Automatic control heavy type anchor winch fairlead with motor-driven hydraulic push rod

A technology of hydraulic push rod and anchor winch, which is applied in the direction of clockwork mechanism and hoisting device, which can solve the problems of many winding layers of drum, damage of steel wire rope, deformed rope surface, etc., and achieve simple structure, flexible rope arrangement, Effect of Precise Rope Synchronization and Reversing Control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

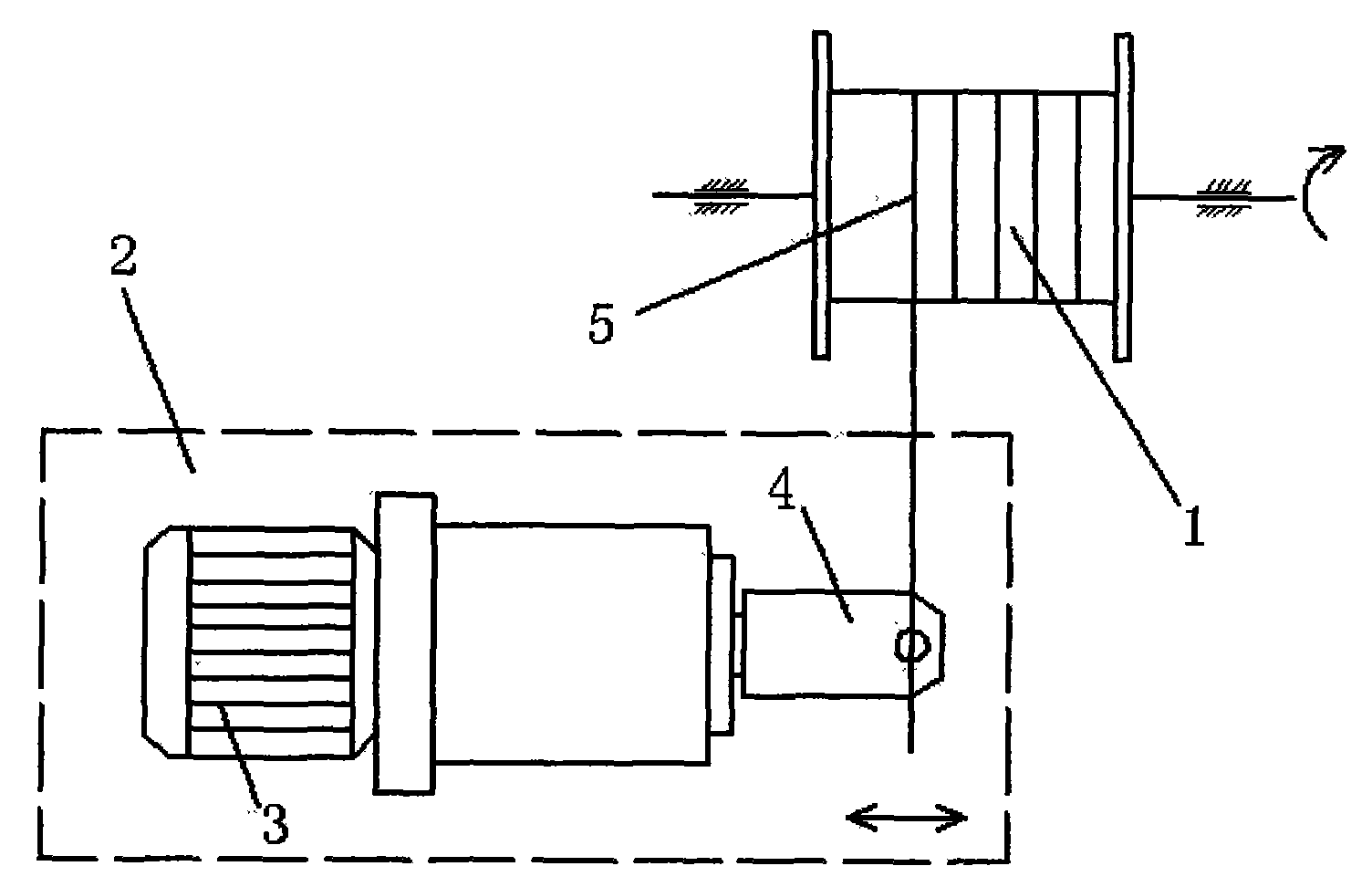

[0022] refer to figure 1 As shown, it is a schematic diagram of the automatic control heavy-duty anchor winch rope rower utilizing the electro-hydraulic push rod in the present invention. The present invention utilizes the electro-hydraulic push rod 2 as the power part of the rope arranging device to realize the reciprocating linear arranging motion of the rope. The electro-hydraulic push rod 2 uses the electric motor 3 as the power source, through the positive and negative rotation of the electric motor 3, and through the control of the internal hydraulic system, the reciprocating linear rowing motion of the push rod head 4 is realized. The reel 1 rotates by itself to wind the wire rope 5 on the reel 1, and one end of the wire rope 5 passes through the circular hole of the push rod head 4, and is driven by the push rod head 4 to carry out a recip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap