Abamectin batch fermentation optimizing process

A technology of abamectin and process, applied in the field of batch fermentation process of abamectin, can solve the problems of increasing tank volume, decreasing dry matter fermentation yield, increasing COD concentration of fermented sewage, etc. The effect of increasing the volume of the tank and reducing the concentration of residual sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through specific examples.

[0017] The production strain used in the present invention is the Streptomyces avermannii strain introduced from China Agricultural University, and the titer of the strain shaker is more than 5500ug / ml; the formula of the initial fermentation liquid is: starch 10%, nitrogen source 4%, Inorganic salts and trace elements 1% ingredients, supplemented with water, the initial loading volume is 70m 3 . Fermentation equipment: 100m 3 Stainless steel fermenter.

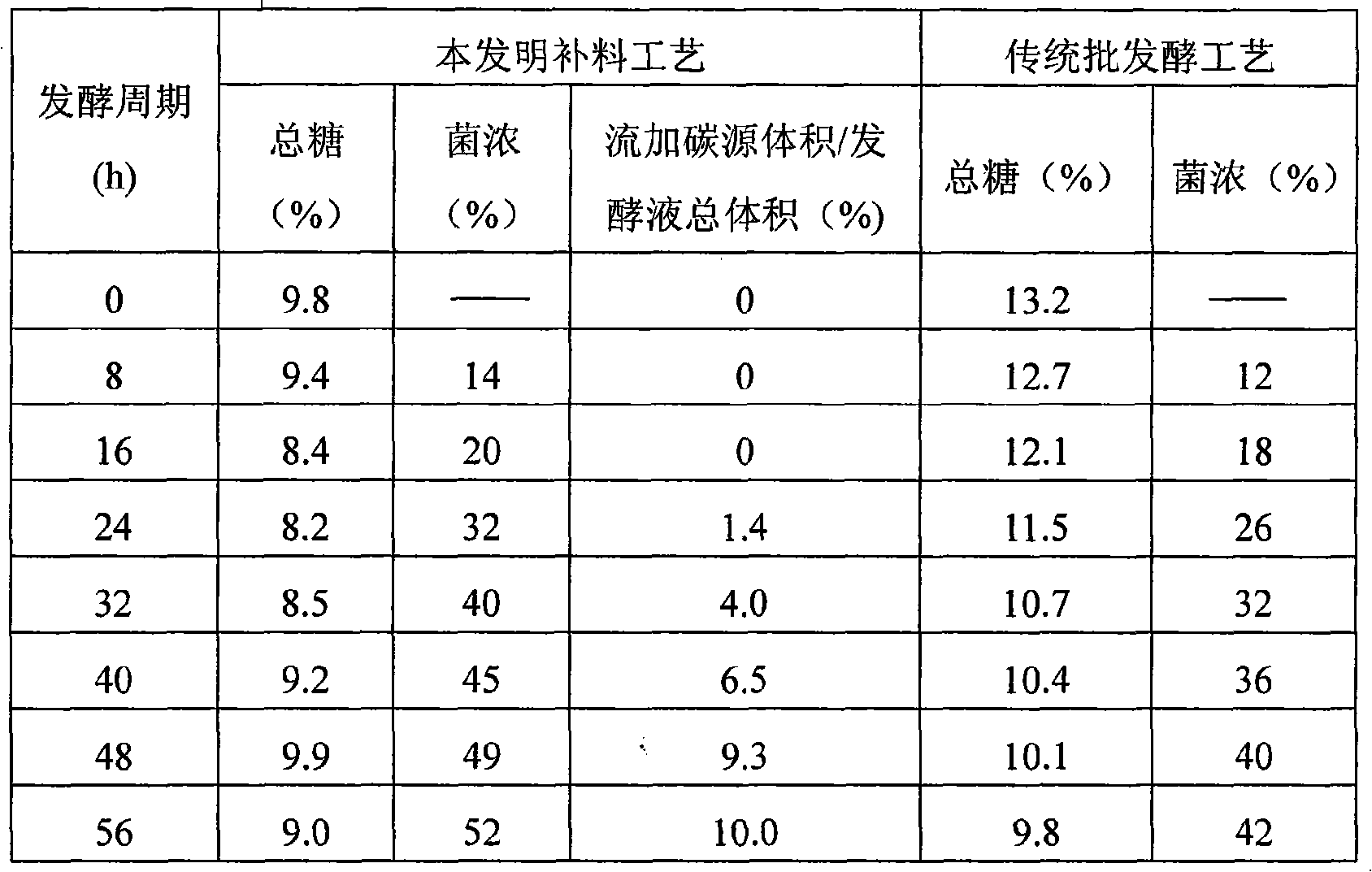

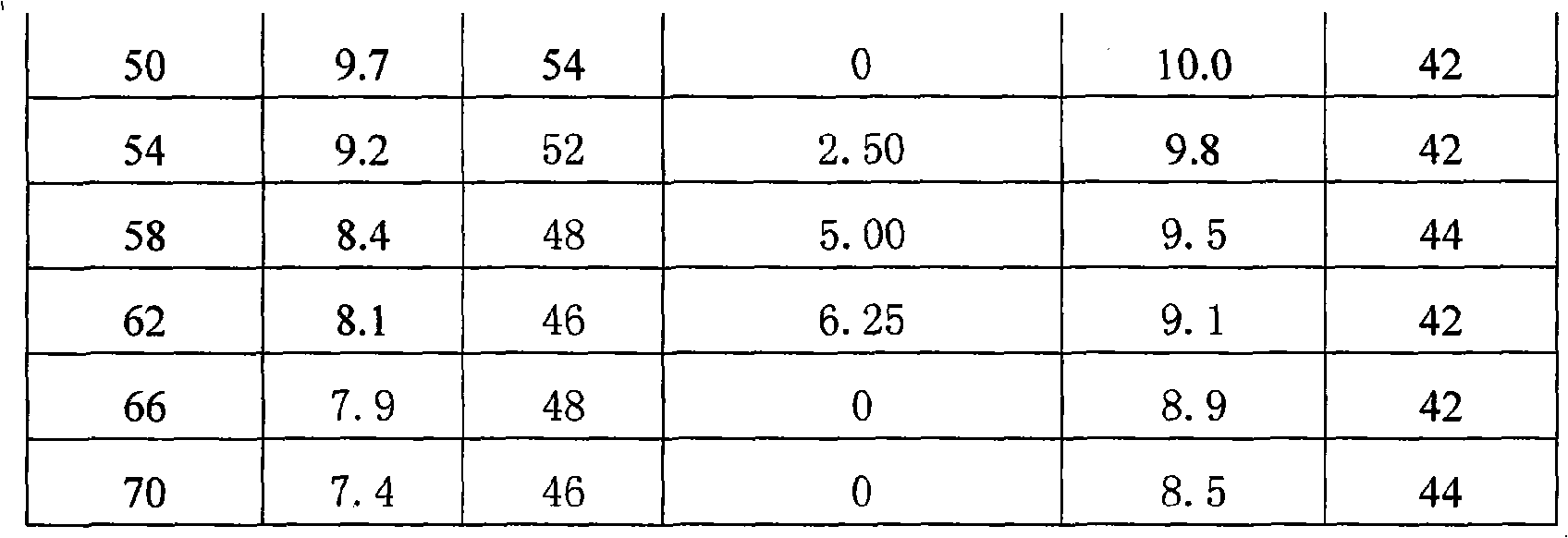

[0018] In the traditional batch fermentation process, the carbon source (total sugar) ratio is about 14%, but the present invention reduces the carbon source concentration in the initial culture medium to about 10%, and reducing the carbon source concentration not only does not have adverse effects on the thalline, but also due to Removing the glucose inhibition can promote the faster growth of the thalline; carry out to 20~30 hours a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com