Reflection type LED lamp and a head lamp for vehicles using the reflection type LED lamp

A technology for automobile headlights and LED lights, applied in the field of lighting, can solve the problems of low brightness, small luminous flux of a single LED, large size of LED headlights, etc., so as to improve the utilization rate of light energy, simplify the structure and production cost, The effect of high utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

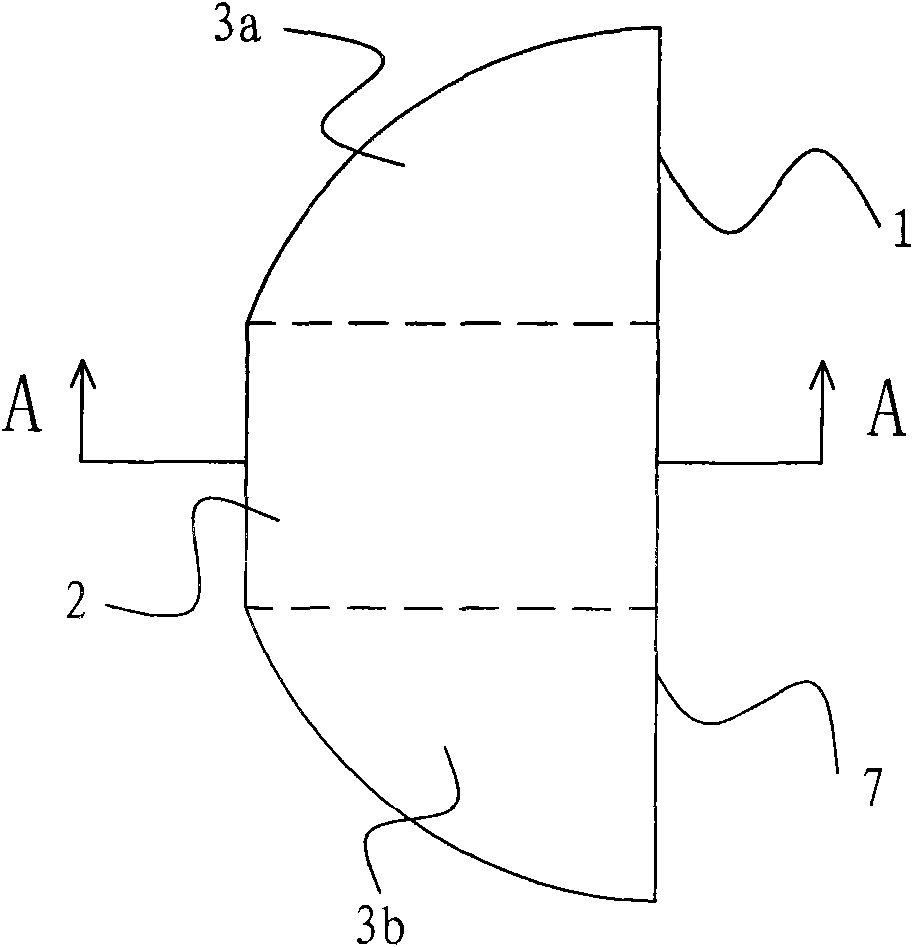

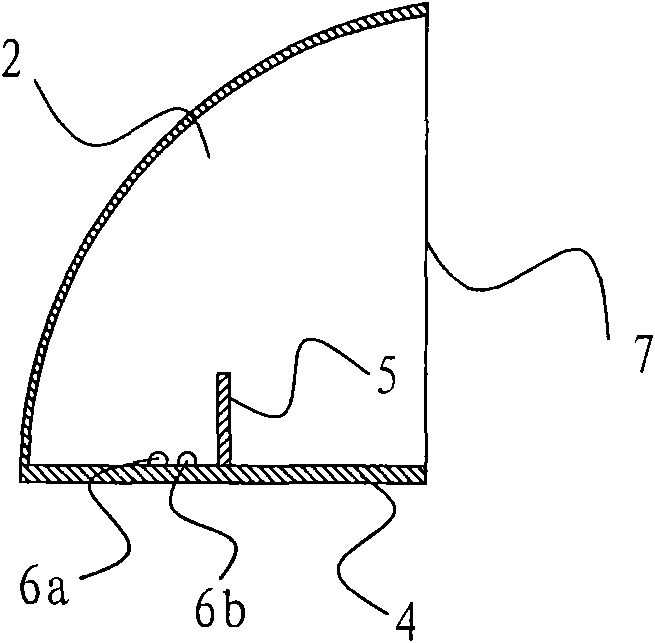

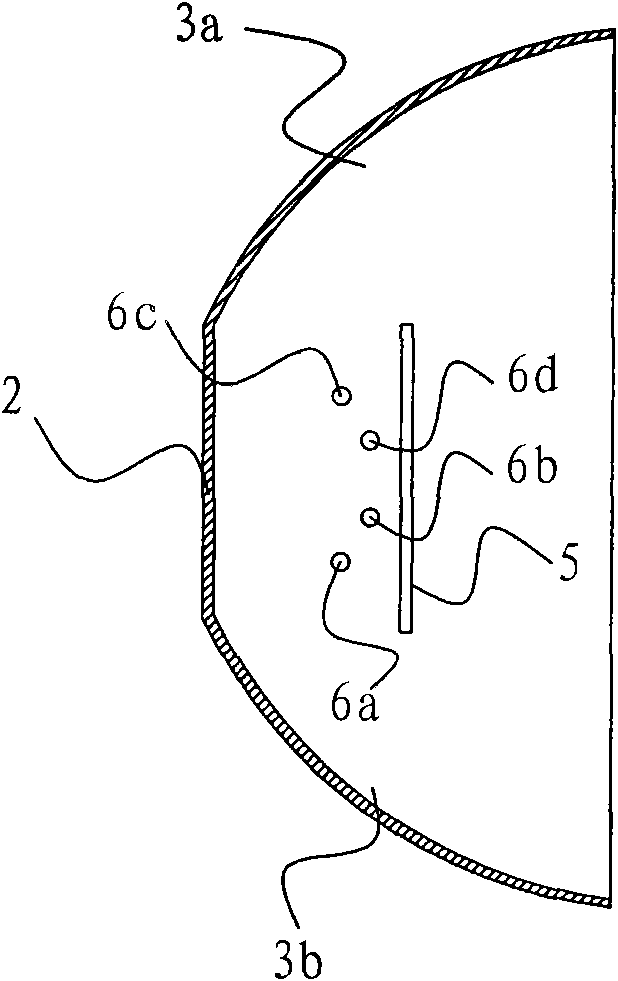

[0032] See attached Figure 1~4 , the reflective LED lamp of the present invention is a housing with a light port 7 surrounded by a base 4 and a reflective cup 1 located above the base 4. The base 4 has an LED light source, and a light source is provided between the LED light source and the light port 7. Reflector 5 facing the plane of the LED light source.

[0033] The LED light source is composed of 4 light-emitting diodes 6a, 6b, 6c, and 6d whose light-emitting parts are vertically upward. The row of light-emitting diodes (light-emitting diode 6b, light-emitting diode 6d) and the back row of light-emitting diodes (light-emitting diode 6a, light-emitting diode 6c) far away from the reflector 5 of the plane.

[0034]In order to realize dislocation distribution, the distance between the light emitting diodes 6a and 6c in the back row is greater than the distance between the light emitting diodes 6b and 6d in the front row, and the distance between the light emitting diodes 6b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com