Rotary hydrostatic testing machine for steel bottles of liquefied gas

A hydrostatic testing machine, liquefied gas technology, applied in the direction of using stable tension/pressure to test material strength, using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of unsatisfactory test results accuracy, work Problems such as low efficiency and poor operation standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

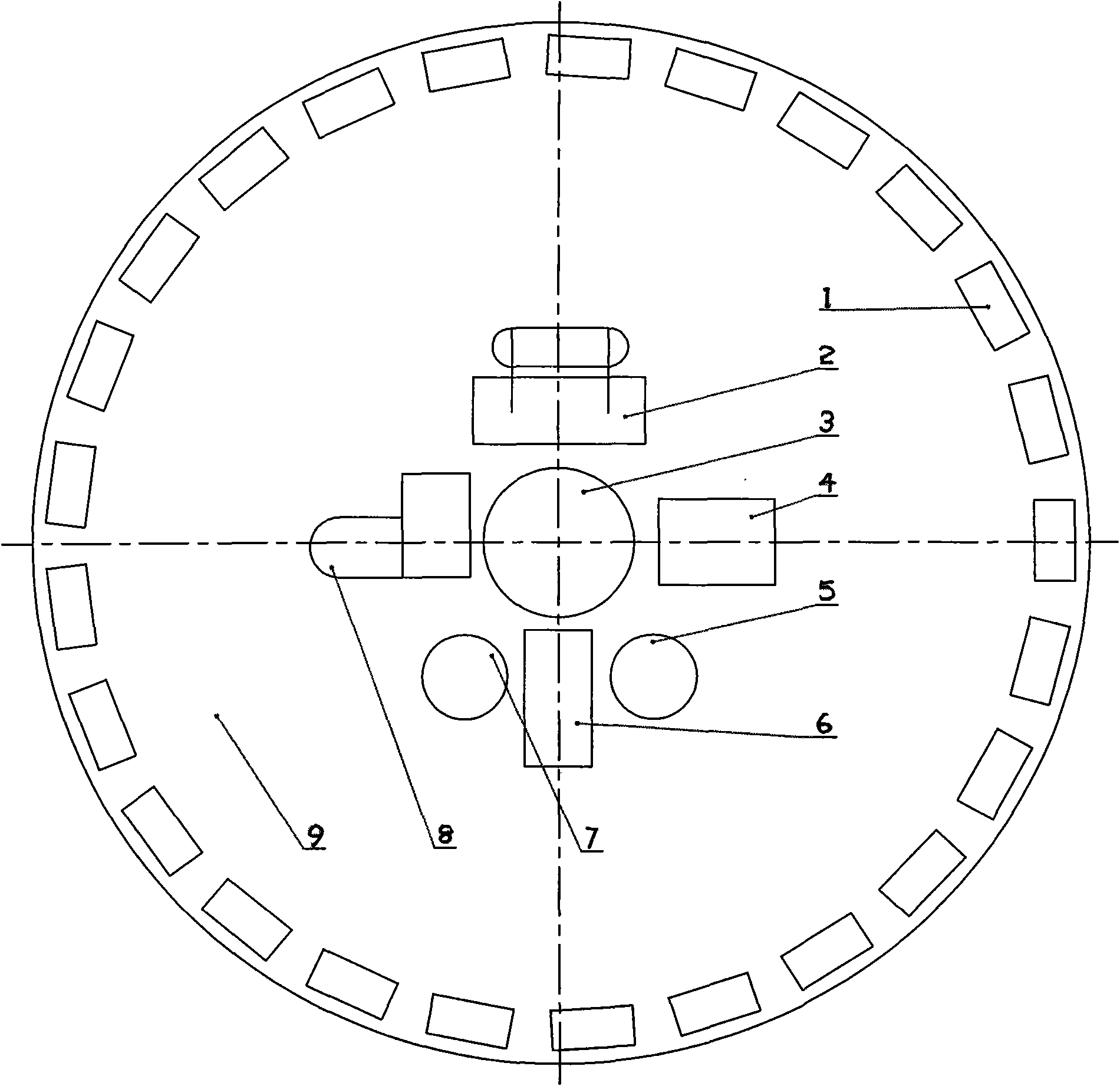

[0016] Such as figure 1 , this example includes a horizontally arranged disc-shaped turntable 9, and the turntable 9 has a central axis mechanism 3 connected to its installation station. Below the turntable 9, a pool is arranged. An autorotation machine 5 for driving the rotation of the turntable is installed on the turntable 9. The autorotation machine 5 includes a motor and a reducer connected with the motor transmission. The reducer drives the central axis mechanism 3 through gears to drive the turntable 9 to rotate.

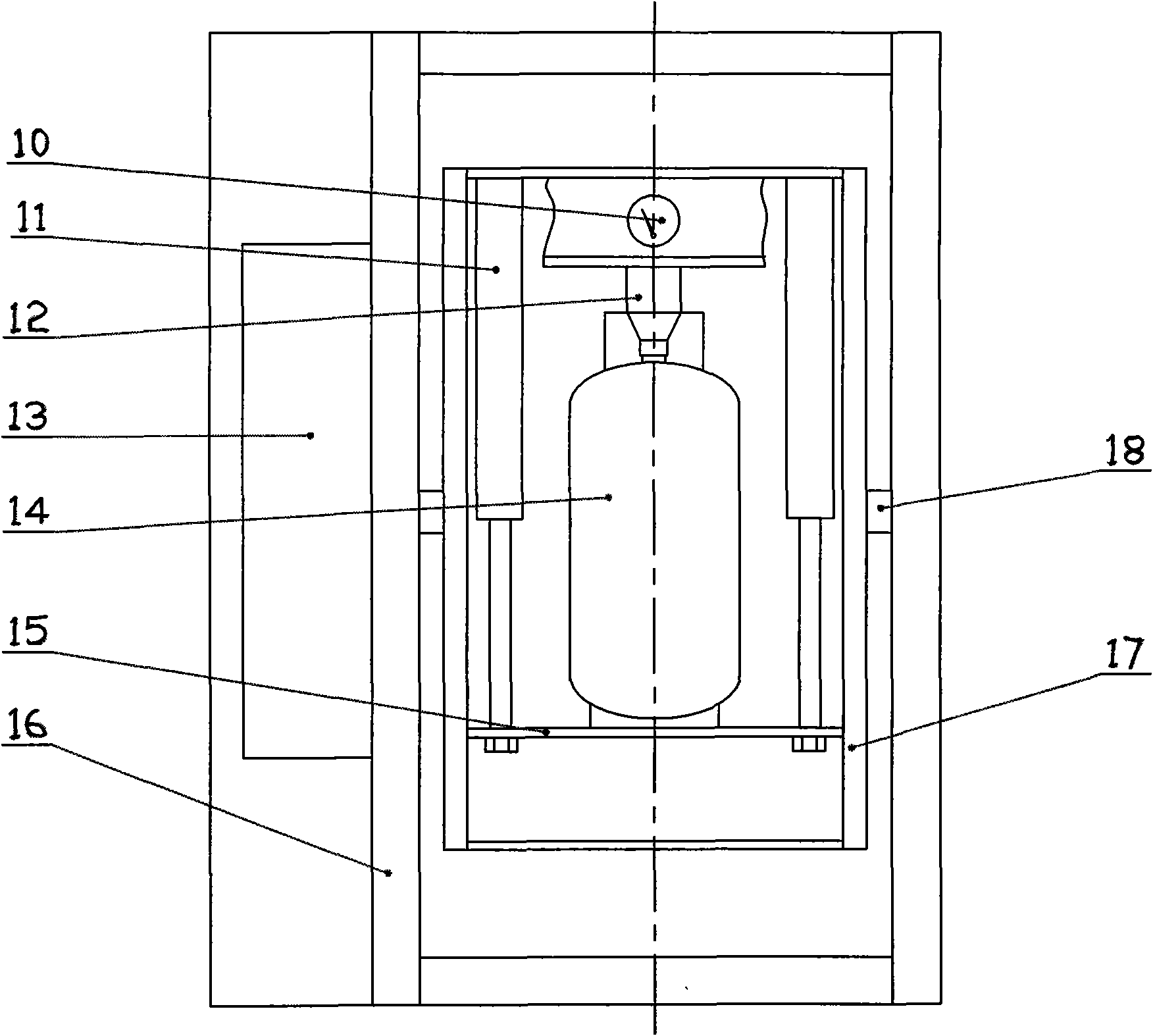

[0017] Several test benches 1 for testing the hydraulic pressure of steel cylinders are installed in the circumferential direction near the outer edge of the turntable 9 . Such as figure 2 As shown, the test bench 1 includes a fixed bracket 16 fixed on the turntable 9 , and an overturn bracket 17 connected to the fixed bracket 16 through an overturn sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com