Resonance element and method for manufacturing the same

A technology of resonant components and resonators, which is applied in the direction of electrical components, waveguide devices, circuits, etc., can solve the problems of increased manufacturing costs and achieve the effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

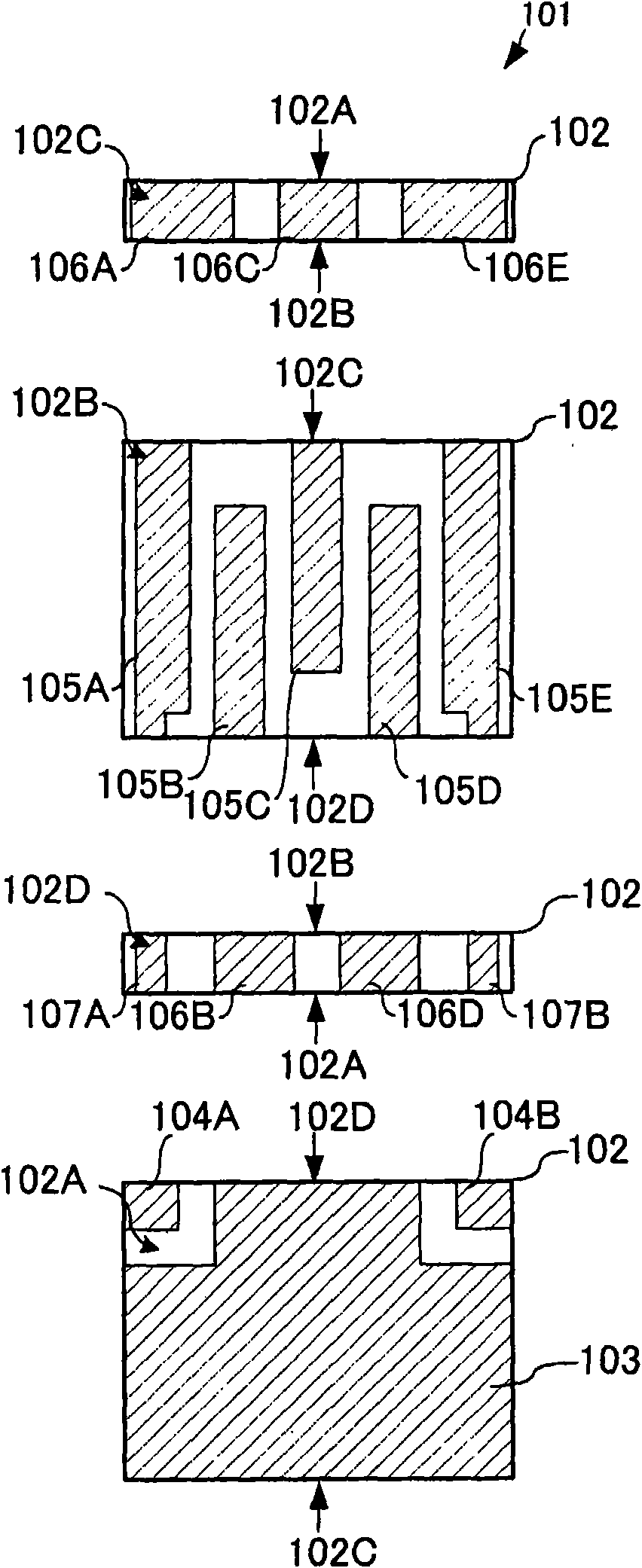

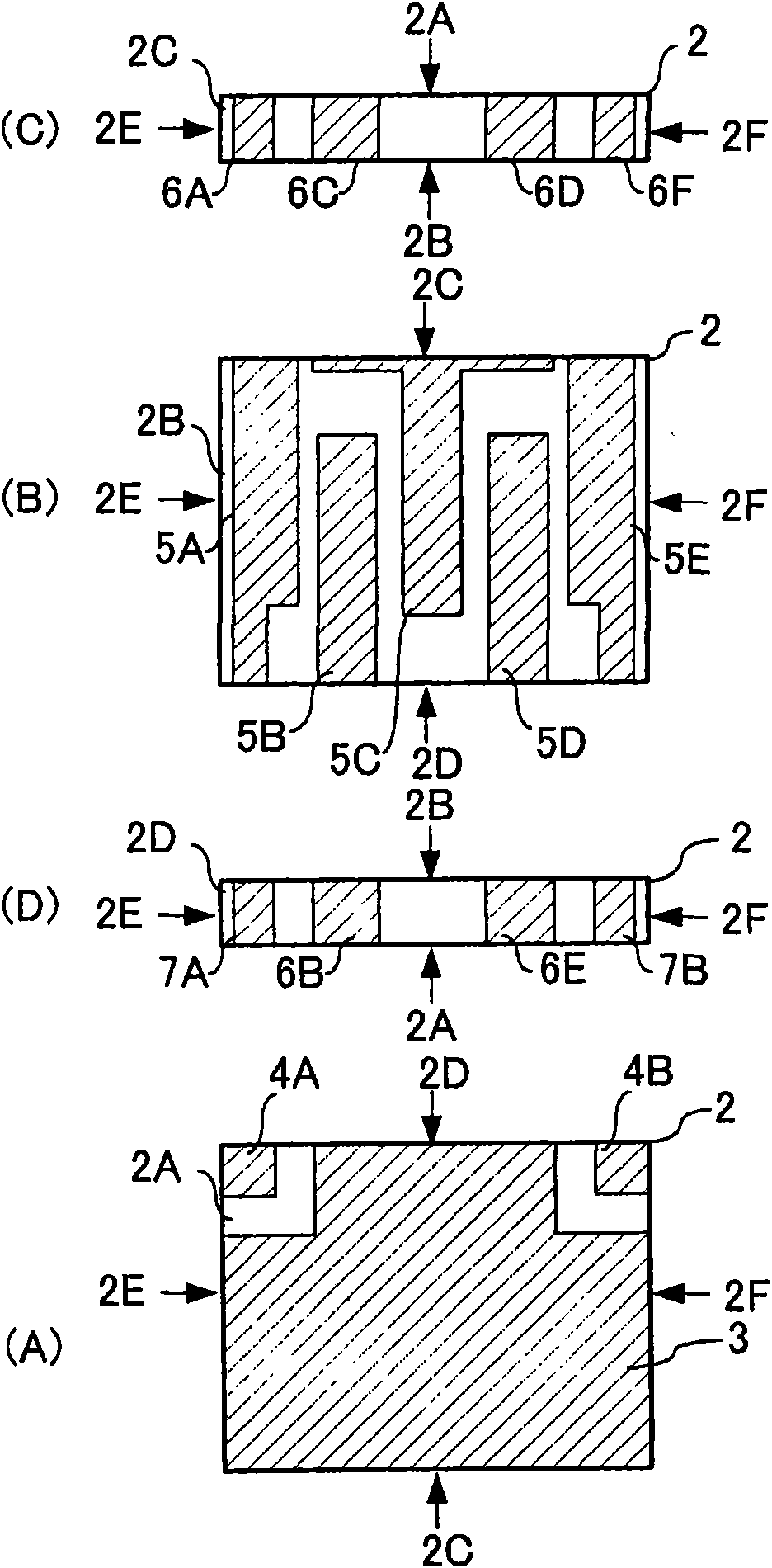

[0028] Hereinafter, the present invention will be described based on a configuration example of a resonance element. figure 2 is a partially expanded view of the resonant element. This resonance element includes a stripline resonator, and is used as a filter for high-frequency, wide-band UWB (Ultra Wide Band) communication.

[0029] This resonance element includes a dielectric substrate 2 in the shape of a small cuboid. The dielectric substrate 2 is made of a ceramic dielectric such as titanium oxide, has a dielectric constant of approximately 110, a substrate thickness of 500 μm, a lateral dimension of approximately 3.2 mm in the figure, and a short-side dimension of the main surface of approximately 2.5 mm.

[0030] In addition, the composition and dimensions of the dielectric substrate 2 can be appropriately set in consideration of frequency characteristics and the like.

[0031] figure 2 The rear main surface 2A of the dielectric substrate 2 shown in (A) is the mounti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com