Novel process method for processing throttle body

A processing technology and throttle body technology, applied in the field of throttle body processing technology, can solve the problems of cumulative positioning error and long process flow unfavorable production efficiency, etc., to reduce equipment occupancy rate, improve parts processing pass rate, and reduce parts The effect of repeated clamping

Inactive Publication Date: 2010-12-01

SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

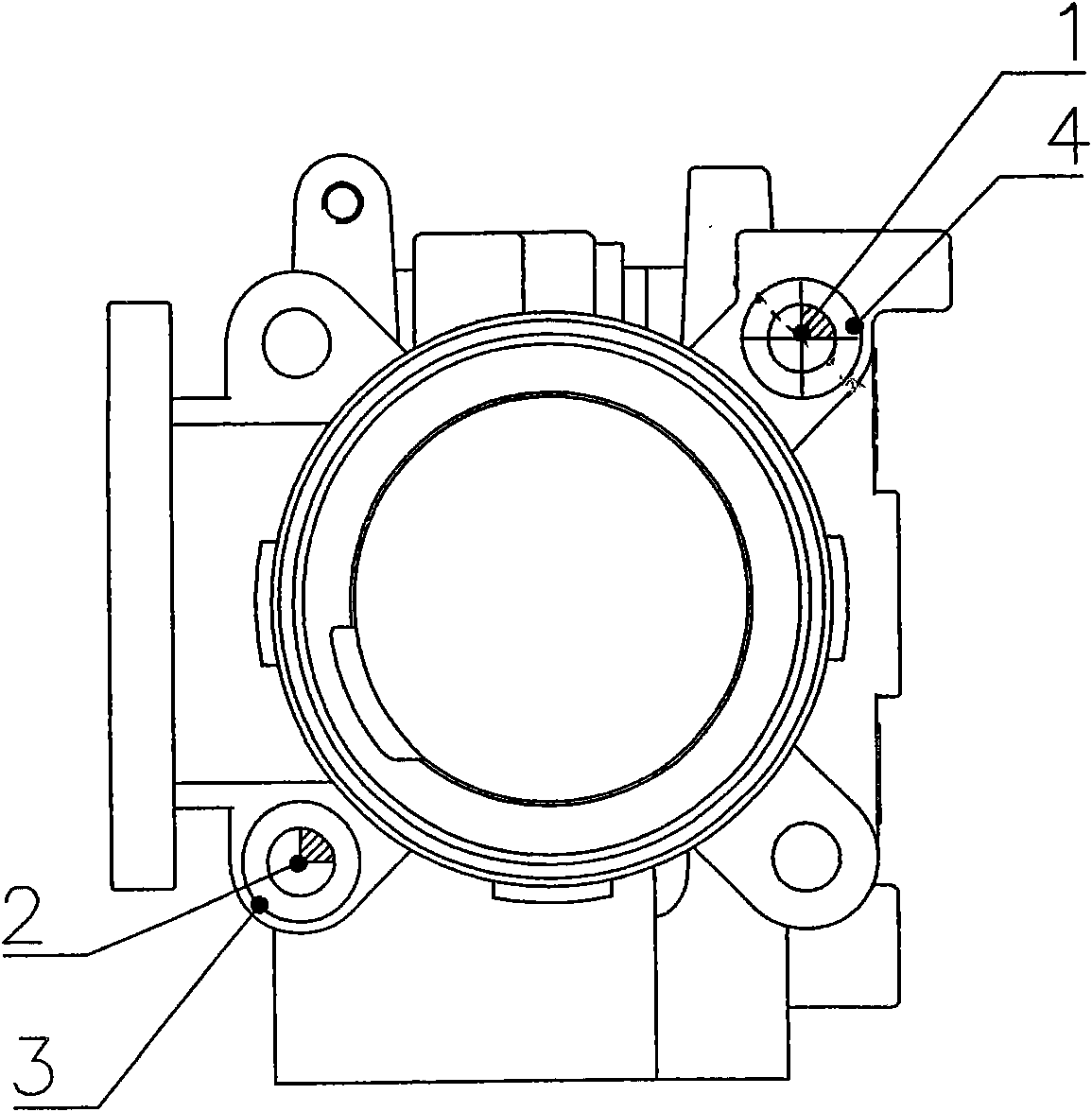

Aiming at the defects and deficiencies of the traditional throttle body processing technology, such as machining fine datum, positioning the workpiece with fine datum, accumulative positioning error in repeated clamping and positioning of the workpiece and long process flow, which is not conducive to improving production efficiency, the present invention proposes to control the quality of the blank , reasonably select the rough datum positioning of the blank, and provide a new fixture design that can overcome the influence of the size of the blank hole and the roundness error, and effectively improve the positioning accuracy of the rough datum

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

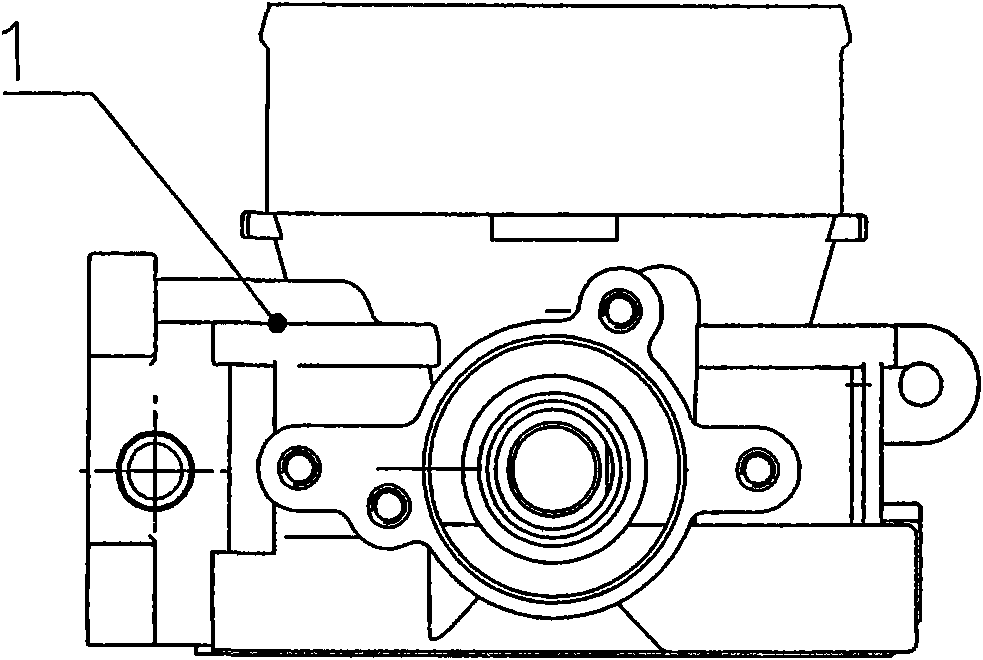

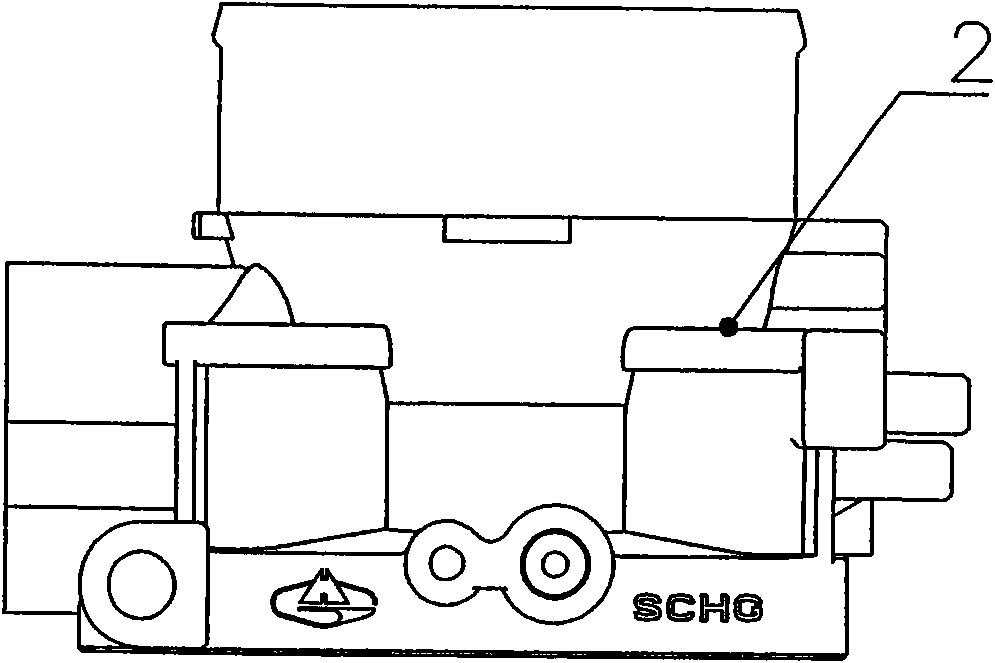

The invention discloses a process method for processing a throttle body, which selects proper blank rough reference according to a die structure by controlling blank quality, and performs clamping and positioning in the rough reference to complete the whole processing procedures, namely complete the processing of the front direction, the rear direction and the upper direction on a rotating table of a processing center and complete the processing in other directions in a multi-axis automatic processing machine production line; and the selection of the blank rough reference is that a fixed die forming part or other blank part of which the size is changed less is selected as the rough reference according to the die structure, the positioning accuracy of the blank rough reference is realized through a special fixture, and the pattern taper of a blank positioning surface is cancelled in die design. The process method cancels the processing procedure of a precise reference, reduces repeat clamping of parts and positioning error, improves the positioning accuracy, and facilitates the improvement of production efficiency and the reduction of occupation rate of equipment.

Description

A new method of throttle body processing technology technical field The invention relates to a mechanical processing technology, in particular to a processing method of a throttle body positioned on the rough reference of a blank. Background technique In the manufacturing industry of auto parts processing, the traditional processing technology of the throttle body generally first processes the fine datum (such as the positioning surface, the positioning hole), and then processes the workpiece with the fine datum positioning. Due to the cumulative positioning error in the repeated clamping and positioning of the workpiece, it is difficult to guarantee the dimensional tolerance of some high precision requirements, and the pass rate of parts processing is not high. Due to the long process and the occupation of more equipment, it is not conducive to improving production efficiency. Contents of the invention The purpose of the present invention is to provide a throttle body ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P15/00

Inventor 肖传良张德政夏秋耕冯伟俞大年

Owner SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com