Mechanical punch brake device

A braking device, mechanical technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, presses, etc. Easy to heat and other problems, to achieve the effect of saving maintenance costs, low power, easy to heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

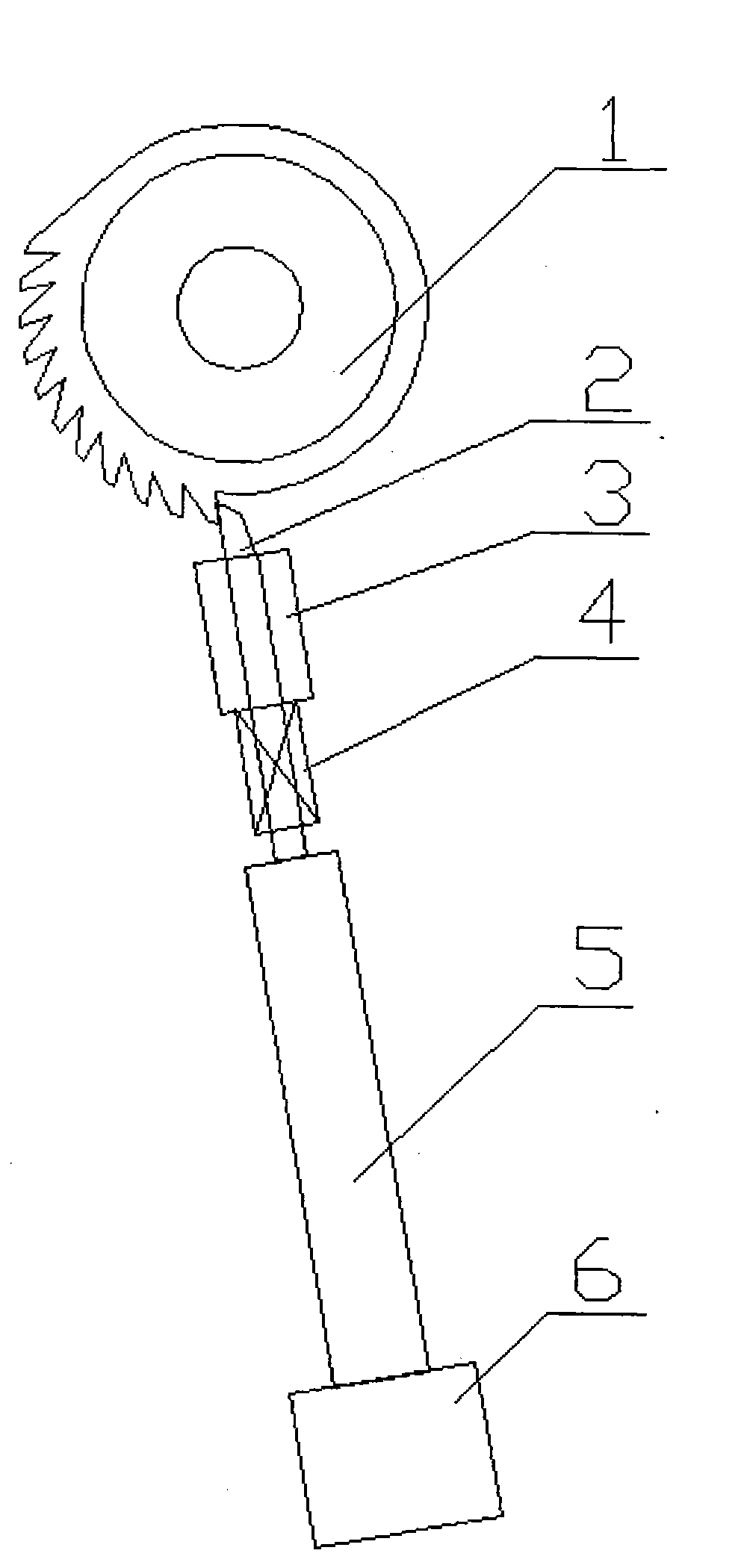

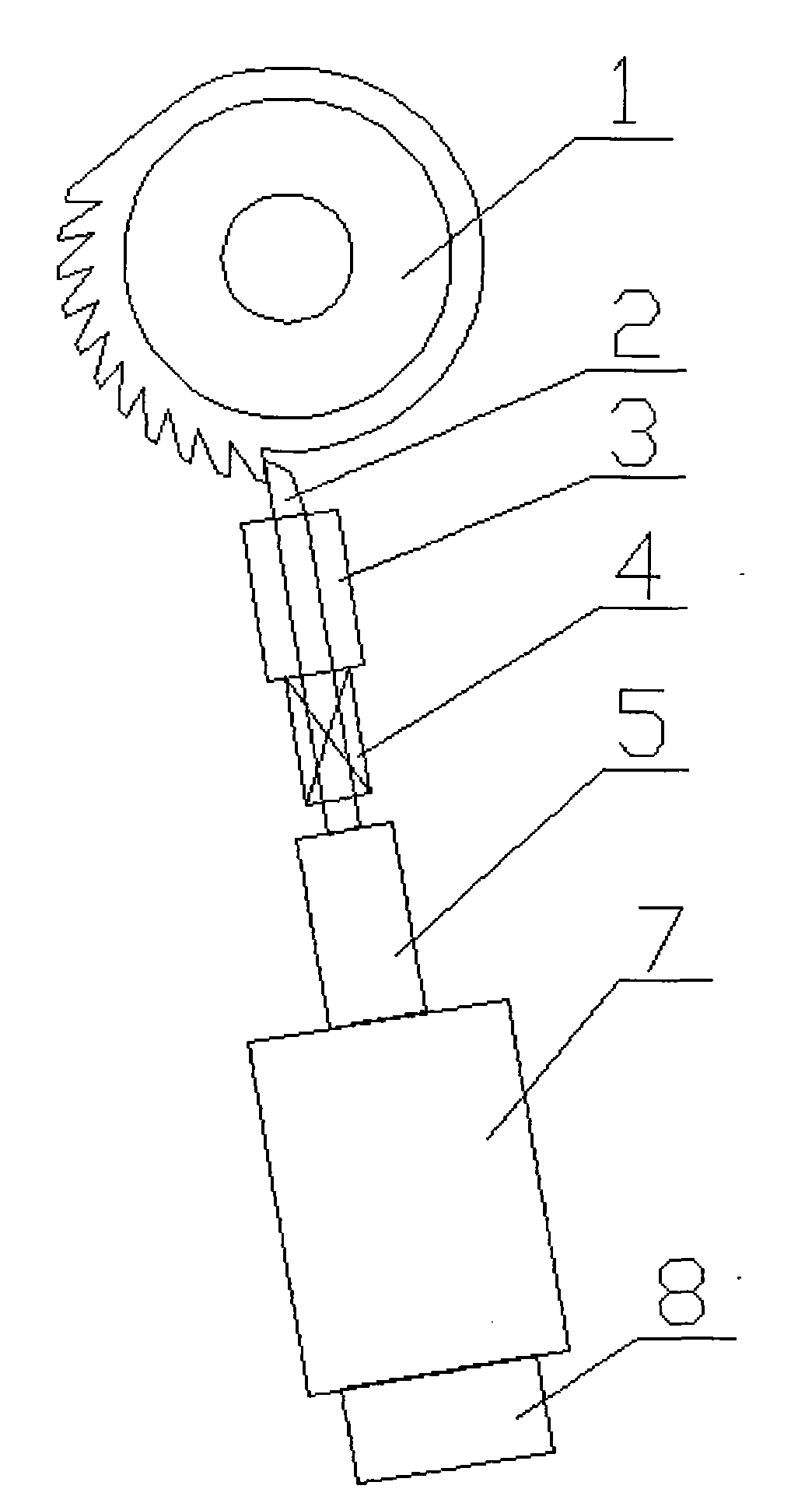

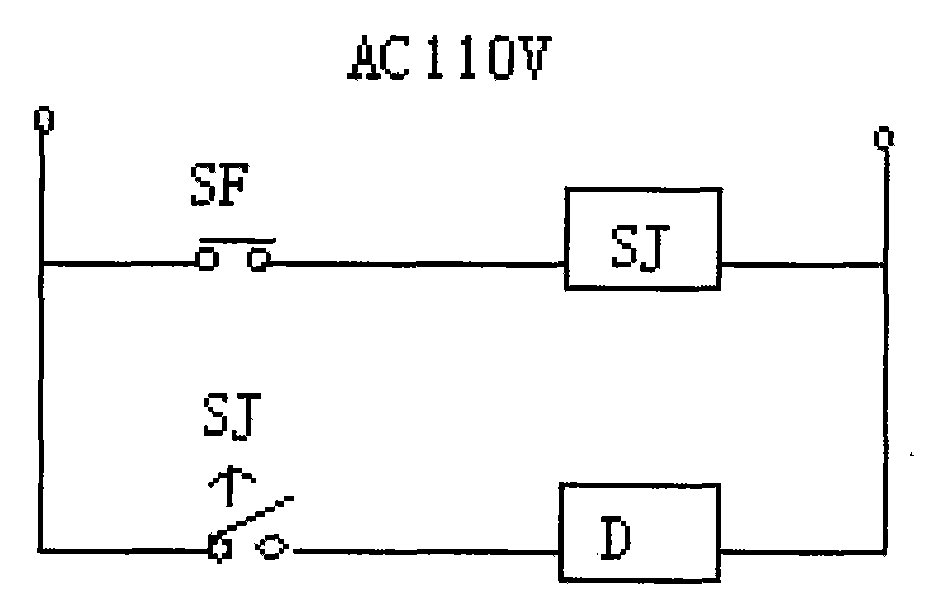

[0014] figure 2 It is a structural schematic diagram of the mechanical braking device in the present invention; image 3 It is the electrical principle diagram of the electromagnetic induction device of the present invention.

[0015] As shown in the figure, the mechanical brake device of the present invention includes a ratchet 1, a brake block 2, a spring 4, a brake block guide 3, a connecting rod 5, a cylinder 7, and an electromagnetic induction device 8. The ratchet 1 cooperates with the brake block 2 to brake The end of the block 2 is inserted into the teeth of the ratchet 1, preventing the rotation of the ratchet 1. The brake shoe guiding device 3 is sleeved on the brake shoe 2, and is fixed on the punch press, and plays a guiding role in the movement of the brake shoe 2. The other end of brake shoe 2 is connected with pull rod 5, is driven by pull rod 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com