Hydraulic decompression device of engine camshaft

A decompression device, camshaft technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of stop lag, stop resistance reduction, exhaust valve can not be completely closed, etc., to achieve smooth start, start resistance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

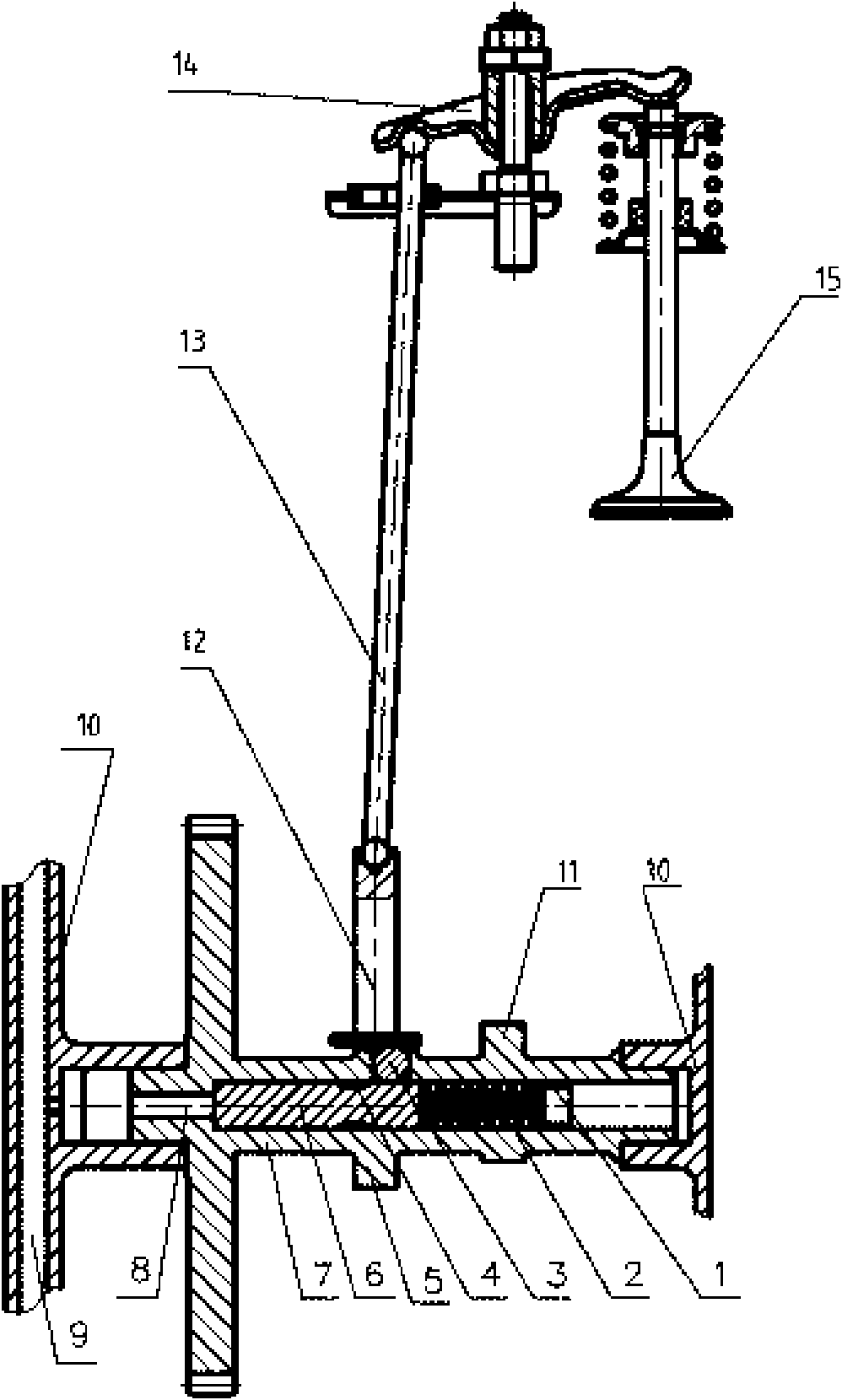

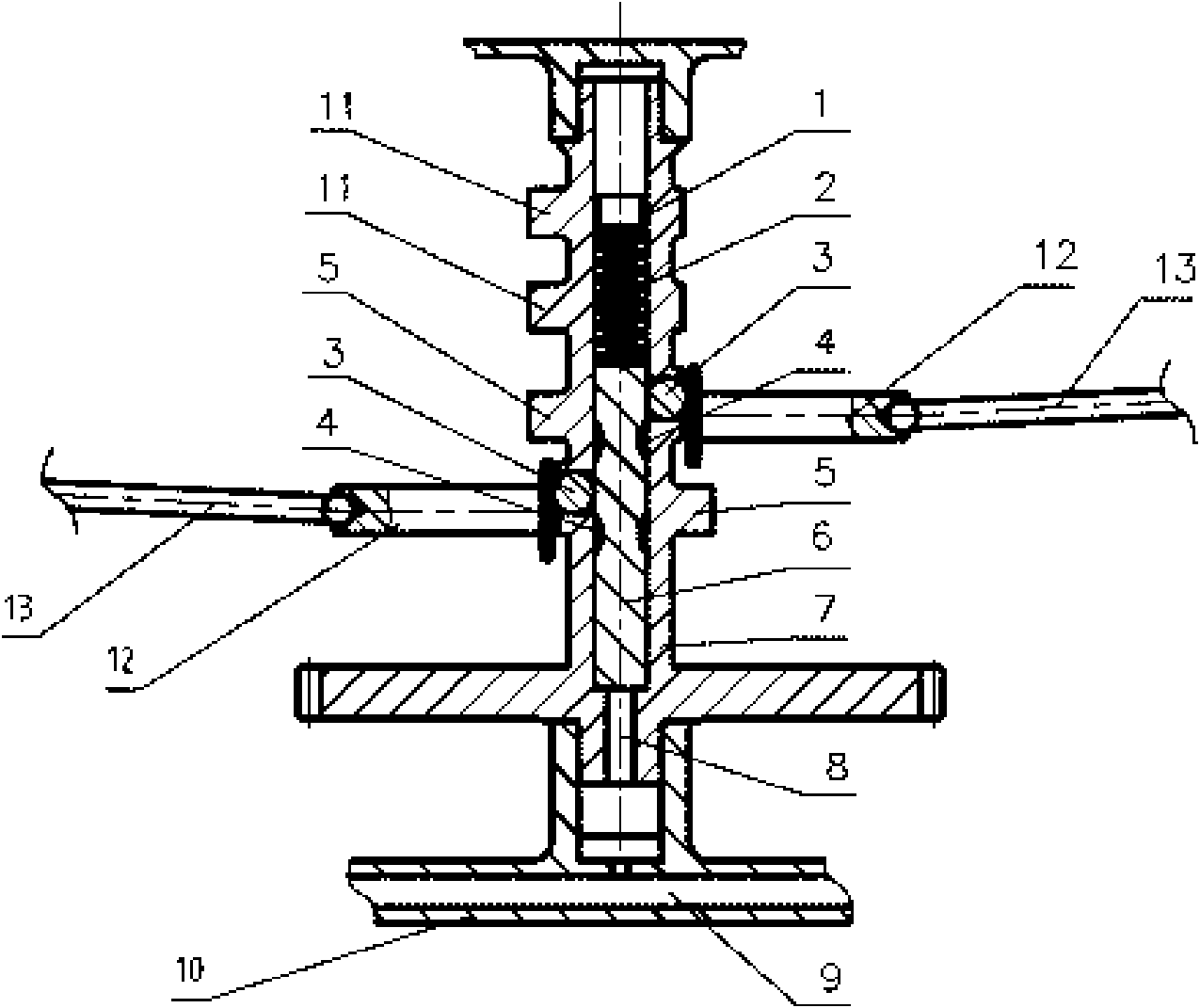

[0016] see figure 1 , is an embodiment arranged on the lower camshaft of the engine. The engine camshaft hydraulic decompression device includes a camshaft 7 provided with an intake cam 11 and an exhaust cam 5 , and the two ends of the camshaft are rotatably supported on the casing 10 . The axial direction of the camshaft 7 is provided with a stepped shaft center hole, the small diameter section of the stepped shaft center hole is a throttle hole 8 communicating with the lubricating oil passage 9 provided on the box body 10, and the exhaust cam 5 is close to the stop stroke base circle In the radial direction, there is a hole for placing the decompression body connected to the large-diameter section of the axial hole. The hole for placing the decompression body is provided with a limit flange at the end of the exhaust cam near the base circle of the stop stroke. A movable decompression body 3 is set in the hole where the decompression body is placed. The decompression body 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com