Polycarbonate film for polaroid and manufacture method thereof

A technology of polycarbonate film and polarizer, applied in optics, optical elements, polarizing elements, etc., can solve the problems of unpopularity, high price, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

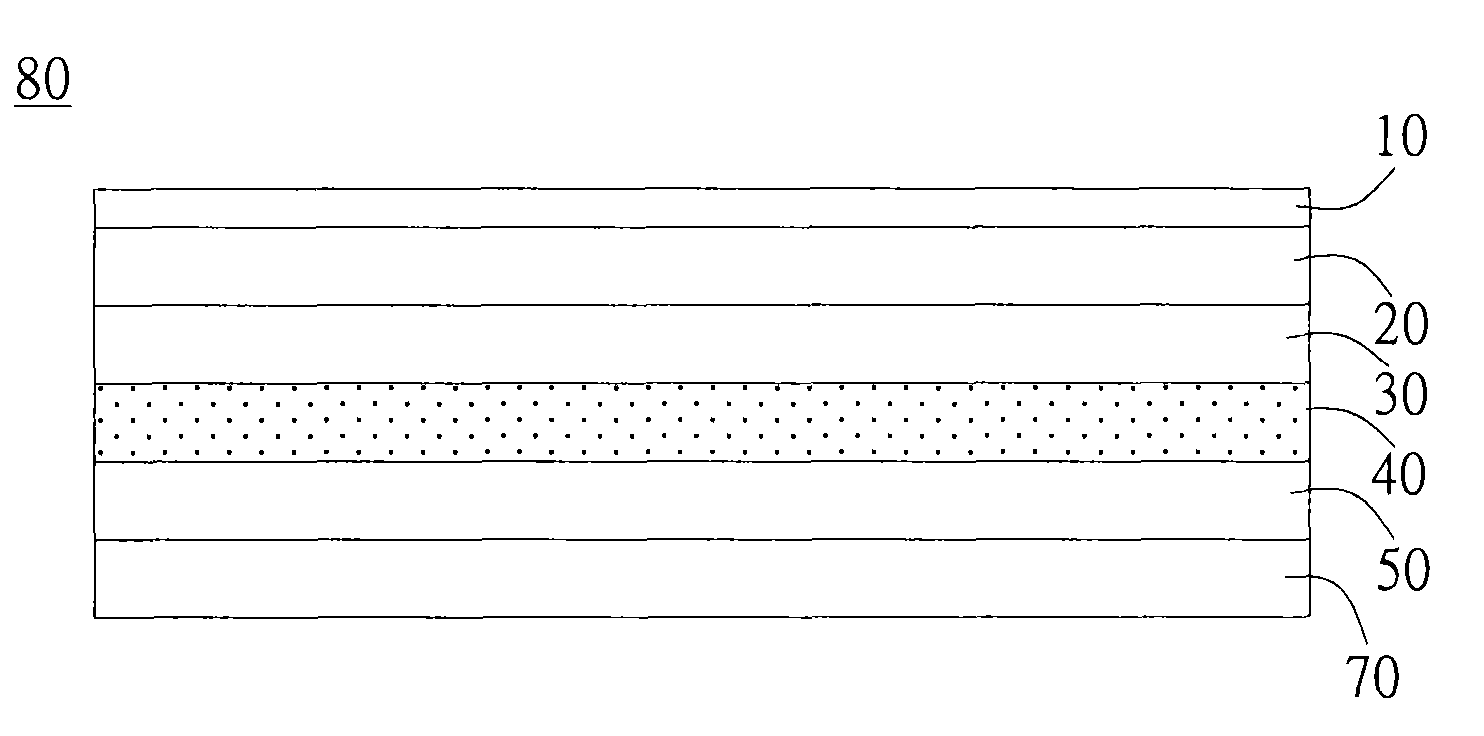

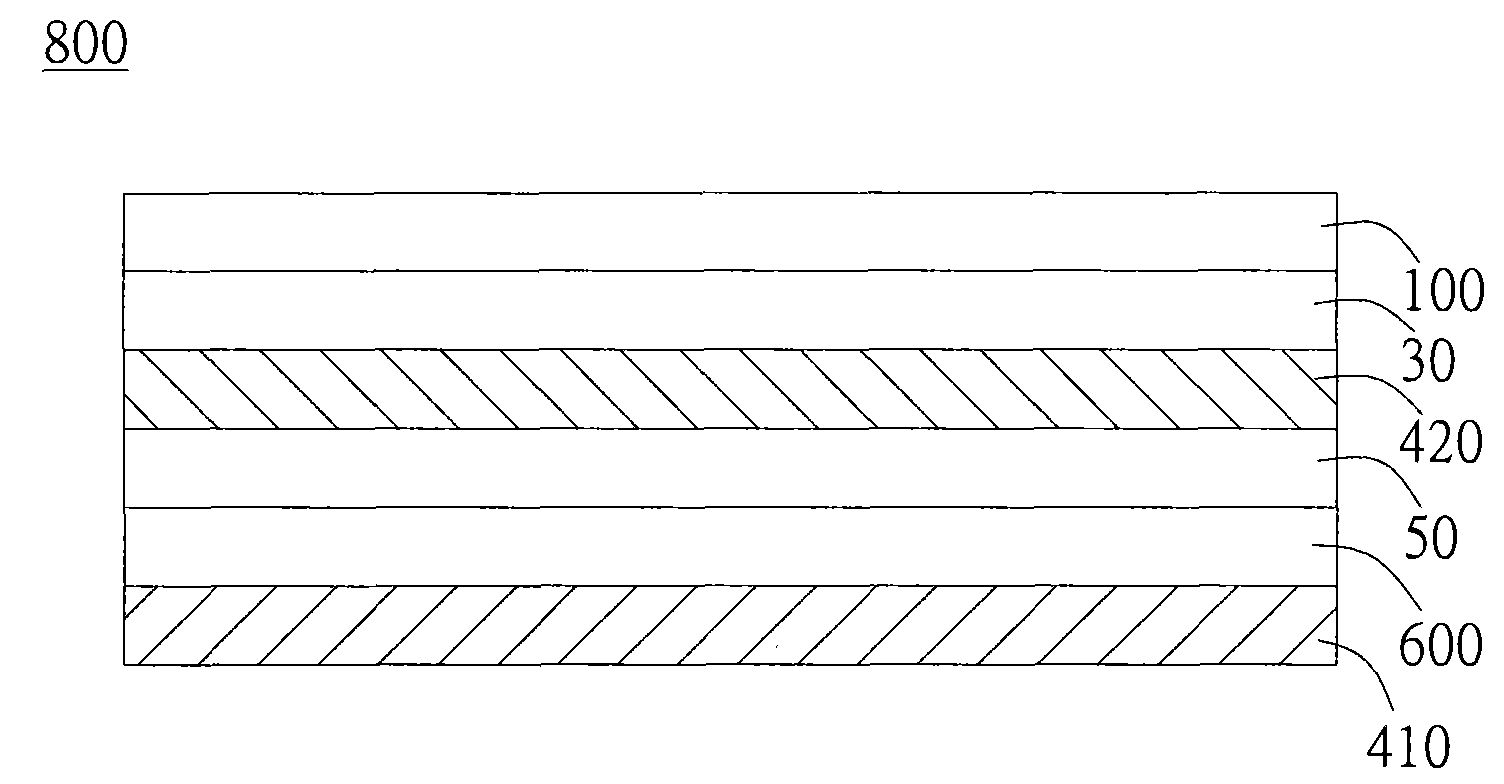

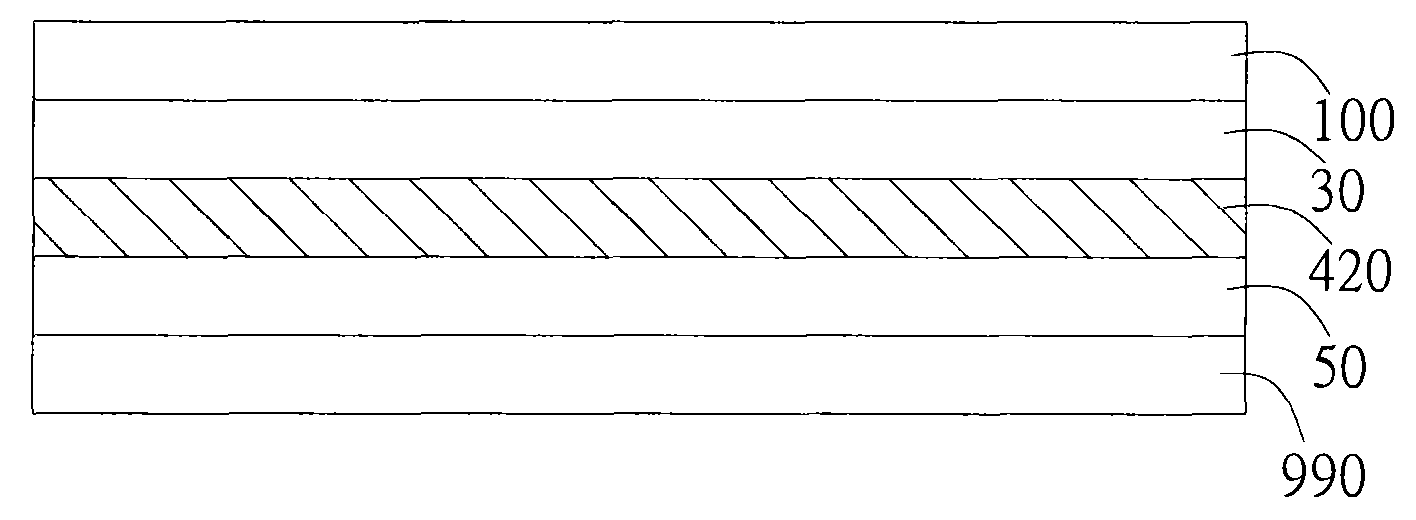

[0020] The invention provides a polycarbonate film used for a polarizer and a manufacturing method of the polycarbonate film. The optical properties of the polycarbonate film used for polarizers of the present invention include: the full spectrum average transmittance is greater than 86%; the haze is less than 1%; the in-plane retardation is less than 15nm; and the out-of-plane retardation is less than 50nm. The polycarbonate film further has mechanical properties such that the ratio of longitudinal strength to transverse strength is between 0.7 and 1.4. Since the polycarbonate material itself does not need to be stretched, it has optical properties close to isotropy, and the material cost is low. Therefore, the polycarbonate film for polarizer of the present invention has isotropic optical properties and low manufacturing cost.

[0021] In a preferred embodiment, the polarizer includes at least a protective film, and the protective film includes a polycarbonate film. Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com