Cascade long-period fiber grating device, manufacturing method thereof, and humidity sensing system

A fiber grating and long-period technology, which is applied in the field of sensor measurement, can solve the problem of low resolution of long-period fiber gratings, and achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

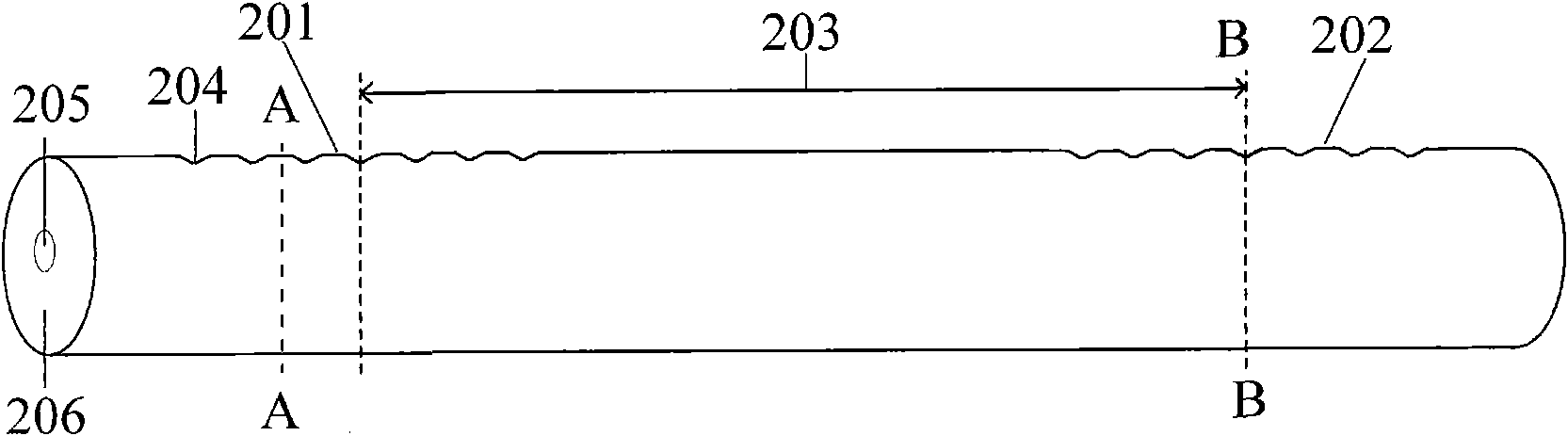

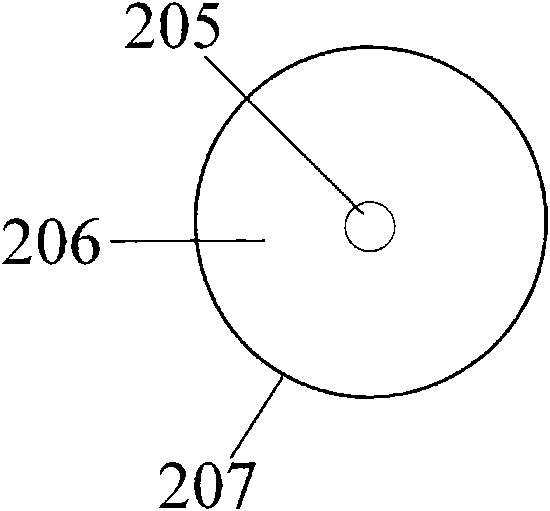

[0052] The cascaded long-period fiber grating device according to this embodiment includes a first long-period fiber grating, a second long-period fiber grating, and an optical fiber. The first long-period fiber grating is used to receive the optical signal and divide it into two paths, one path is transmitted through the fiber core, and the other path is coupled to the fiber cladding for transmission. The light intensities of the two paths separated by the first long-period fiber grating are equal, and it is preferable to make the two paths of light intensities equal during the manufacturing process, and it is also possible to be unequal, but the interference contrast will be relatively poor. The second long-period fiber grating is used to receive the transmitted two-way optical signals through the optical fiber, and couple the optical signals transmitted in the optical fiber cladding back to the optical fiber core. The distance between the center of the first long-period fib...

Embodiment 2

[0060] In this embodiment, the hydrogel humidity sensitive film is coated on the surface of the cascaded long-period fiber grating device in embodiment 1 to form a humidity sensor, which includes two asymmetric long-period fiber gratings separated by a certain distance, and Hydrogel humidity sensitive membrane.

[0061] One of the preferred implementations of the humidity sensor, such as image 3 As shown, the humidity sensor includes: two first long-period fiber gratings 301 and a second long-period fiber grating 302 whose transmittance is 3dB, the distance between the two gratings is L, and the fiber cladding between the two gratings The surface is coated with a hydrogel humidity sensitive film 303 to realize the perception of changes in the humidity of the external environment.

[0062] Such as Figure 4 It is a structural diagram of another embodiment of the cascaded long-period fiber grating humidity sensor. Its structure is basically the same as that of Example 1, exce...

Embodiment 3

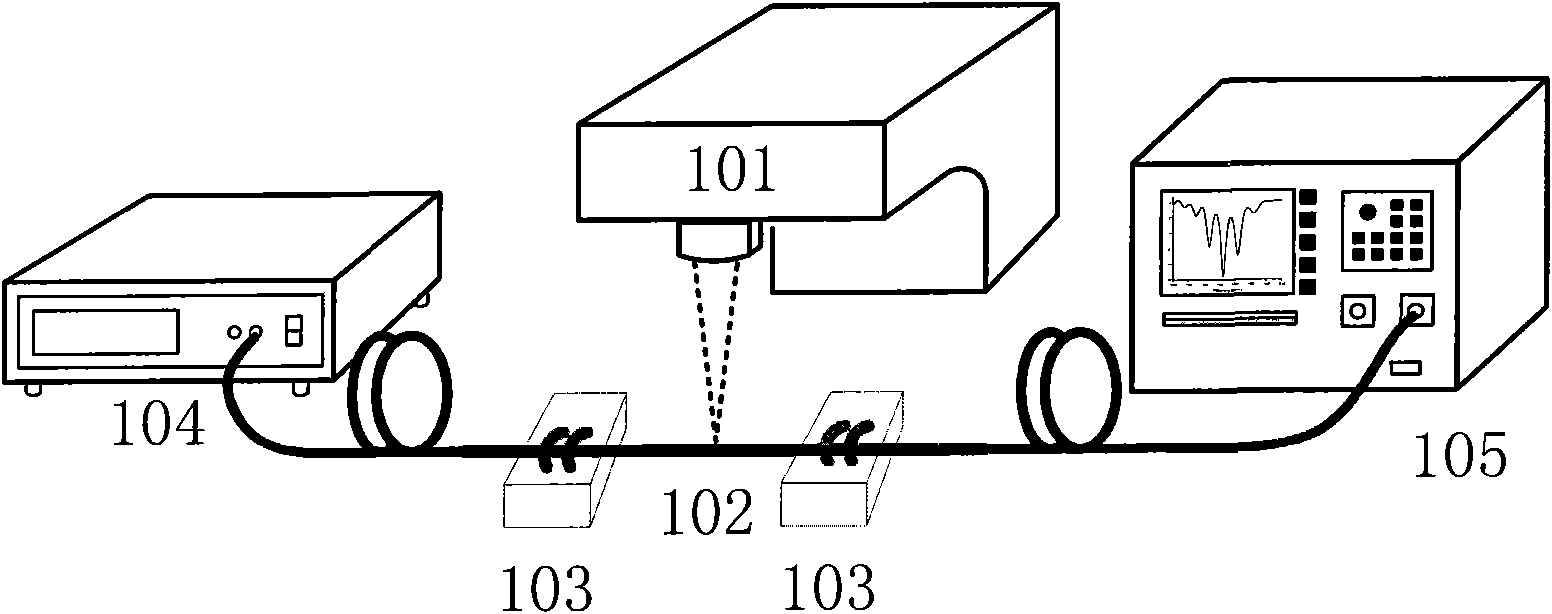

[0065] Such as Figure 5 As shown, the humidity sensor includes two asymmetric long-period fiber gratings 501 and 502 separated by a certain distance L with a transmittance of 3 dB, and a hydrogel humidity sensitive film 503 . The hydrogel humidity-sensitive film 503 is produced by the method of soaking combined with ultraviolet lamp irradiation film formation. First, a layer of hydrogel is coated on the surface of the optical fiber cladding by the soaking method, and then the hydrogel-coated cascade length The two ends of the periodic fiber grating device are fixed with optical fiber clamps 504 to ensure that the entire optical fiber is in a straight state, and the entire optical fiber is placed under an ultraviolet lamp 505, and polymerization is initiated by ultraviolet light irradiation to obtain a hydrogel humidity sensitive film 503 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com