Colored composition, color filter, and method for production of the color filter

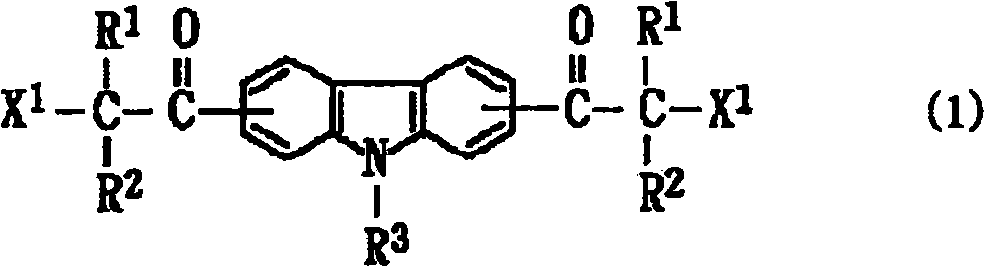

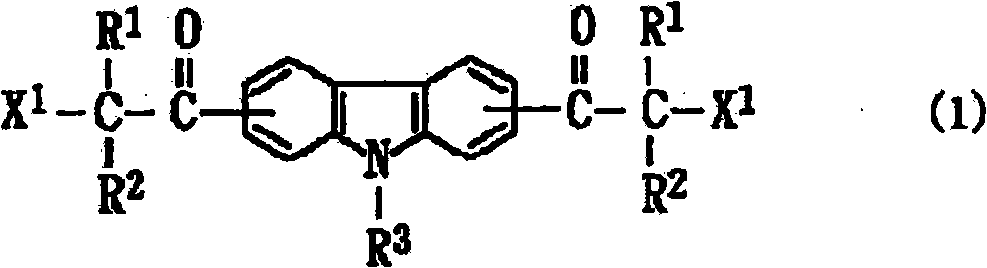

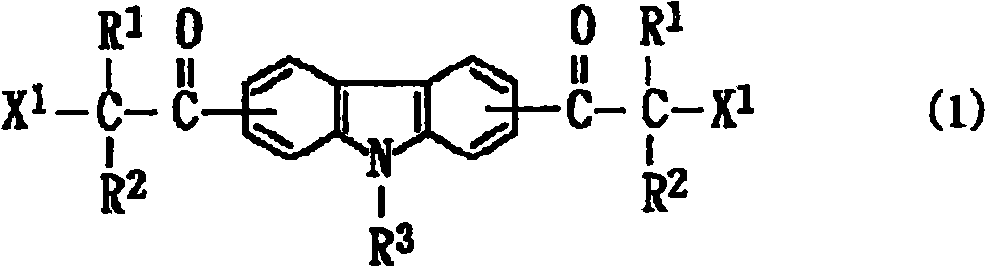

一种着色组合物、制造方法的技术,应用在仪器、滤光片、图纹面的照相制版工艺等方向,能够解决光聚合引发剂昂贵、阻碍感光性着色组合物固化、运送或成本不利等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] (Preparation of Coloring Composition)

[0097] The coloring composition can be prepared by finely grinding the pigment and, if necessary, the above-mentioned pigment dispersant using various dispersing means such as a three-roll mill, a two-roll mill, a sand mill, a kneader, and an ultrafine pulverizer. After dispersing in a monomer having an ethylenically unsaturated double bond, and if necessary, a transparent resin and an organic solvent, a photopolymerization initiator is added. Moreover, you may manufacture the coloring composition for color filters containing two or more types of pigments after finely dispersing each pigment in monomer etc. which have an ethylenically unsaturated double bond, respectively, and mixing.

[0098] The coloring composition preferably removes coarse particles of 5 μm or larger, preferably 1 μm or larger, more preferably 0.5 μm or larger coarse particles and mixed dust by means of centrifugation, sintered filter, membrane filter, and the...

Embodiment 1~22、 comparative example 1-4

[0149] After the mixture of the formulations shown in the following tables 4, 5, and 6 containing the previously prepared pigment dispersions R-1, G-1, B-1, and BM-1 shown in the above table 1 was uniformly stirred and mixed, the Filter through a 1 μm filter to obtain coloring compositions of various colors.

[0150] The formulations of the coloring compositions of each color are shown in Table 2 below. In addition, the following Table 3 shows the molar absorptivity (ε 308 ) and molar absorptivity at 365nm (ε 365 ).

[0151]

[0152] Pigment dispersion: previously prepared pigment dispersion

[0153] Acrylic resin solution: previously prepared acrylic resin solution 1

[0154] Photopolymerization initiator: substances shown in Table 3 below

[0155] Monomer 1: dipentaerythritol hexaacrylate

[0156] ("ARONIX M-402" manufactured by Toagosei Co., Ltd.)

[0157] Monomer 2: Multifunctional acrylate containing carboxyl groups

[0158] ("TO-1382" manufactured by Toagosei ...

Embodiment 8

[0201] What embodiment 8 used is the molar absorptivity (ε) under 308nm 308 ) is less than the molar absorptivity at 365nm (ε 365 ) of the photopolymerization initiator 7, but there are parts where the linearity is poor locally, and the film reduction rate is also slightly deteriorated, but it is to the extent that it does not affect the use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com