Soft capsule and preparation method thereof

A technology of soft capsules and soft capsule skins, applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as leakage, soft capsule skin degeneration, local deformation, etc., and achieve uniform toughness and softness , Guarantee the effect of activity and full glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) To make an inner coating film, weigh 41 g of liquid paraffin, 13 g of povidone K30, 16 g of polyacrylic acid resin II, 25 g of polyvinyl alcohol 400, 5 g of citric acid, and 95 g of salad oil. Fully mix the above raw materials in the coating liquid storage tank, emulsify at a temperature of 50°C, emulsify for 40 minutes until the material liquid is evenly mixed, and then stand at room temperature for later use;

[0027] Wherein, liquid paraffin, povidone K30, polyacrylic acid resin II, polyvinyl alcohol 400, citric acid are solutes, and salad oil is a solvent.

[0028] (2) making capsule skins, fully mixing the raw materials for producing capsule skins in glue tank 1 for subsequent use;

[0029] (3) melt the mixture in the glue tank 1 in step (2) at a temperature of 60° C. for 2 hours to obtain glue;

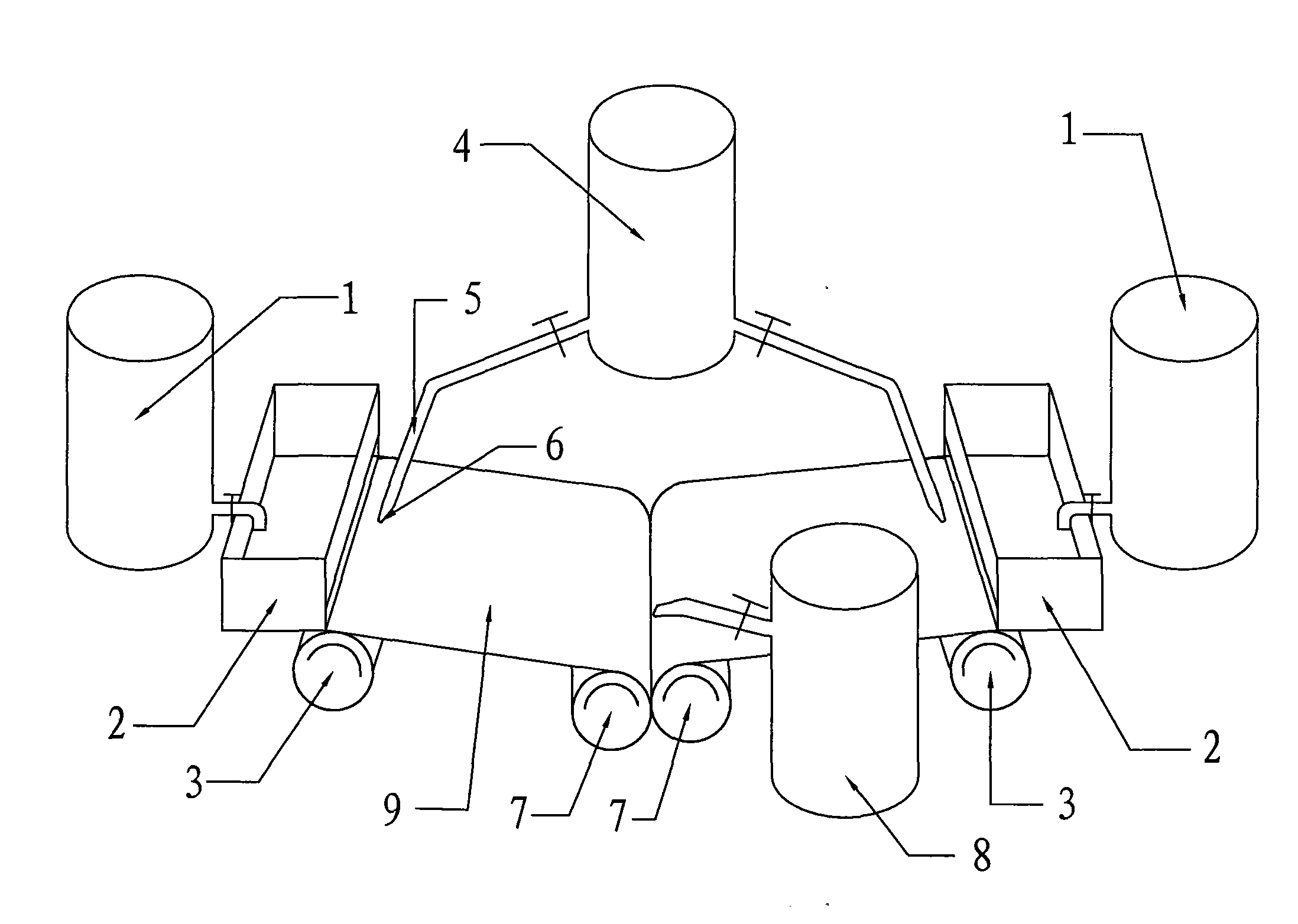

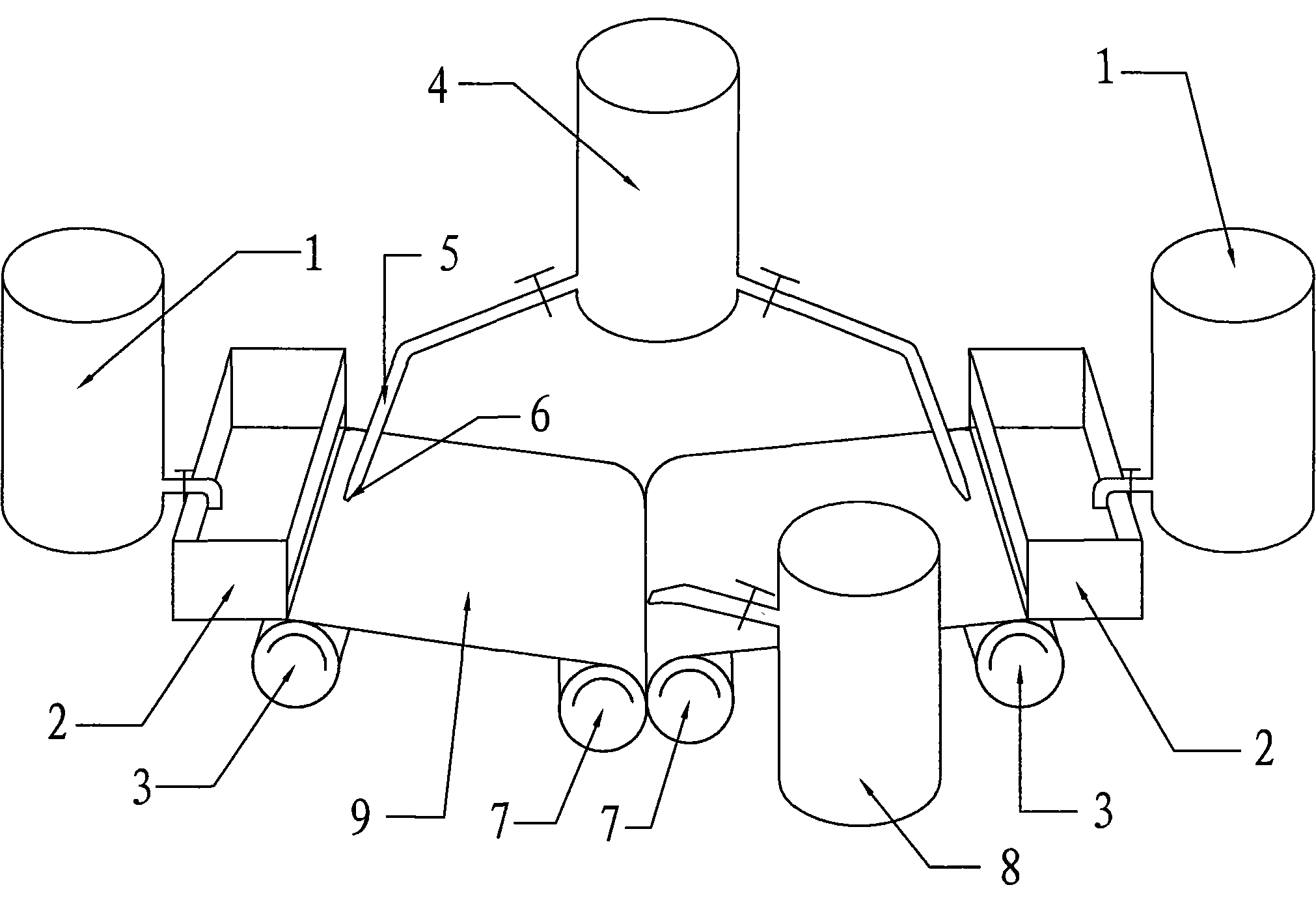

[0030] (4) The glue liquid obtained after melting the glue in the glue tank 1 through the step (3) flows into the rubber box 2 through the rubber tube, and the glue ...

Embodiment 2

[0035] Prepare soft capsule of the present invention, comprises the steps:

[0036] (1) To make an inner coating film, weigh 25g of liquid paraffin, 15g of povidone K3015g, 20g of polyacrylic acid resin II, 40030g of polyvinyl alcohol, 10g of citric acid and 130g of salad oil. Fully mix the above raw materials in the coating liquid storage tank, emulsify at a temperature of 40°C, emulsify for 3 hours until the material liquid is evenly mixed, and let it stand at room temperature for later use;

[0037] Wherein, liquid paraffin, povidone K30, polyacrylic acid resin II, polyvinyl alcohol 400, citric acid are solutes, and salad oil is a solvent.

[0038] (2) making capsule skins, fully mixing the raw materials for producing capsule skins in glue tank 1 for subsequent use;

[0039](3) melt the mixture in the glue tank 1 in step (2) at a temperature of 75° C. for 0.6 hours to obtain glue;

[0040] (4) The glue liquid obtained after melting the glue in the glue tank 1 through the ...

Embodiment 3

[0045] Prepare soft capsule of the present invention, comprises the steps:

[0046] (1) To make an inner coating film, weigh 50g of liquid paraffin, 10g of povidone K3010g, 10g of polyacrylic resin II, 40020g of polyvinyl alcohol, 10g of citric acid and 60g of salad oil. Fully mix the above raw materials in the coating liquid storage tank, emulsify at a temperature of 60°C, emulsify for 30 minutes until the material liquid is evenly mixed, and stand at room temperature for later use;

[0047] Wherein, liquid paraffin, povidone K30, polyacrylic acid resin II, polyvinyl alcohol 400, citric acid are solutes, and salad oil is a solvent.

[0048] (2) making capsule skins, fully mixing the raw materials for producing capsule skins in glue tank 1 for subsequent use;

[0049] (3) melt the mixture in the glue tank 1 in step (2) at a temperature of 55° C. for 4 hours to obtain glue;

[0050] (4) The glue liquid obtained after melting the glue in the glue tank 1 through the step (3) fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com