Combined type solid-liquid separation device

A solid-liquid separation and composite technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as paralysis, separation system damage, and different precipitation speeds, and achieve reasonable structure, high-efficiency solid-liquid separation, Safe and reliable effect of separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below by embodiment, the present invention will be further elaborated in conjunction with accompanying drawing:

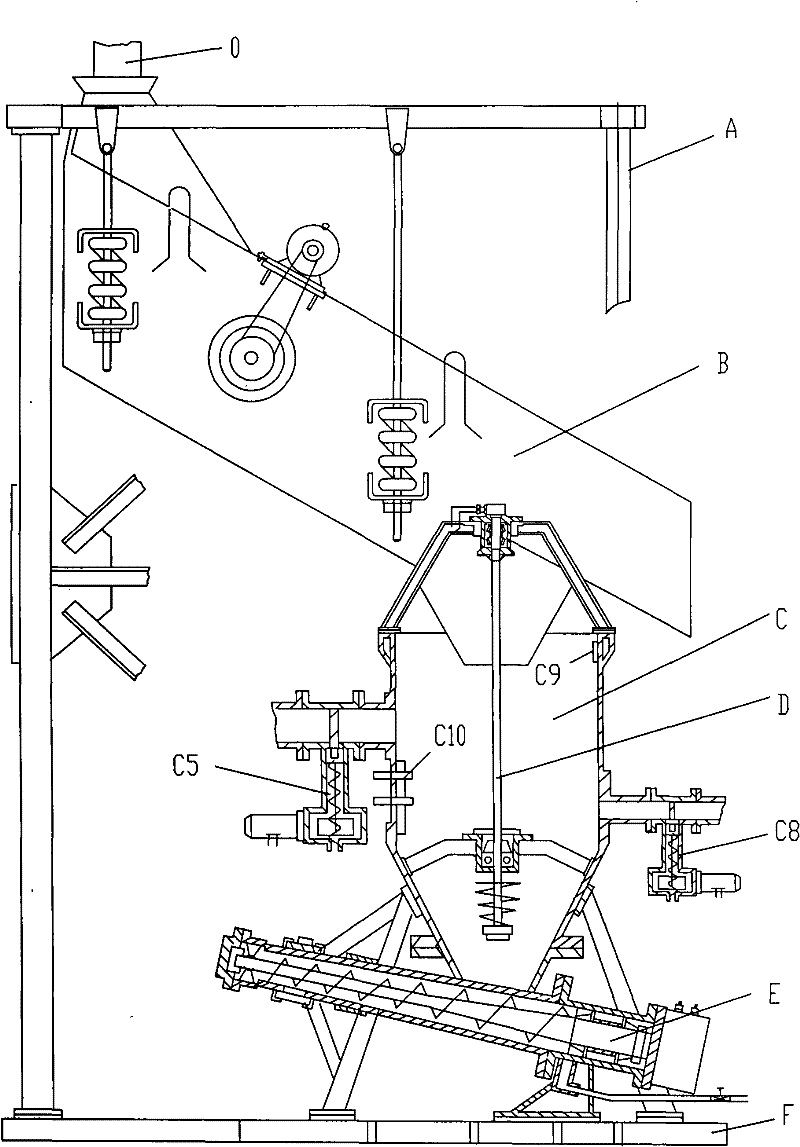

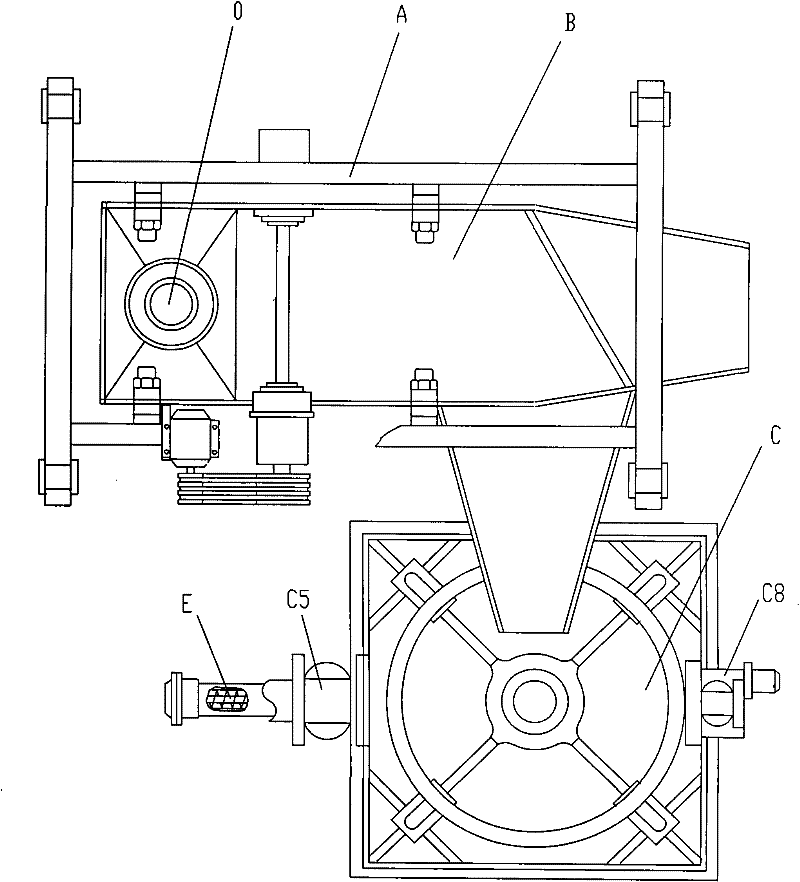

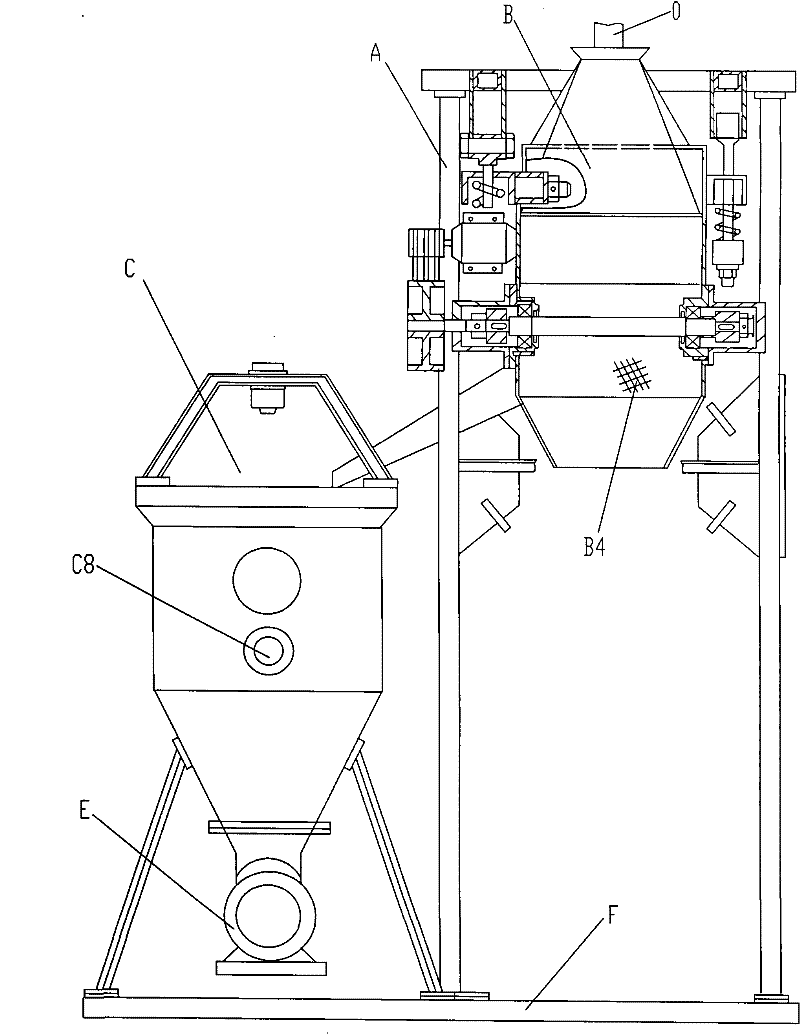

[0037] see figure 1 , figure 2 , image 3 , embodiment composite solid-liquid separation device, comprising mud feed valve O, frame A, eccentric vibrating residue filter B, storage sedimentation bin C, vertical screw conveyor D, variable diameter screw squeezer E, base F and control system J. The material storage and sedimentation bin C is fixed on the base F, and the wall of the material storage sedimentation bin C is provided with a discharge valve C5 and a suspension valve C8, and the discharge valve C5 is located above the suspension valve C8; the rack A is located On the side of the sedimentation bin C, the eccentric vibrating residue filter B is installed obliquely on the frame A, and the eccentric vibrating residue filter B is connected with the mud feed valve O and the storage sedimentation bin C; the vertical screw conveyor D is located in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com