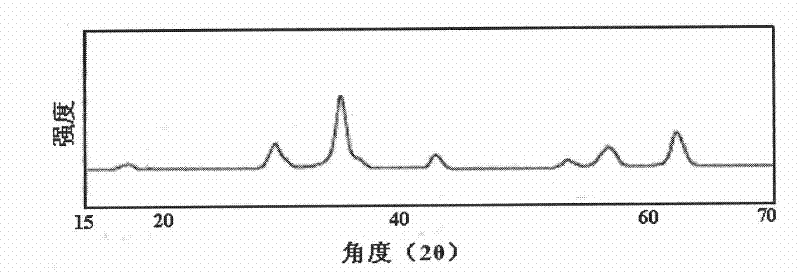

Nanometre complex solid superacid and preparation and application thereof

A solid super acid, nano-composite technology, applied in the preparation of carboxylate, the preparation of organic compounds, catalyst activation/preparation, etc., can solve the problems of unfavorable industrialization promotion, large specific surface area, high preparation cost, and low production cost. , Large specific surface area, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a) press n (Fe 2+ ):n(Zn 2+ )=2.0:1 Weigh FeSO 4 ·7H 2 O and ZnSO 4 ·7H 2 O, mixed and ground into powder;

[0028] b) According to n(NaOH):n(Fe 2+ )=1.8:1 Add NaOH solution, and press n(PEG):n(Fe 2+ )=0.04:1 Add the dispersant polyethylene glycol (PEG-600), and stir at 50-70°C for 30-60 minutes;

[0029] c) Press n (NaHCO 3 ):n(Fe 2+ )=2.0:1 adding NaHCO 3 Solid, adjust pH=10, stir at 50-70°C for 10-20 minutes;

[0030] d) Aging at 20-40°C for 10 hours, suction filtering, and washing the obtained precipitate with absolute ethanol until neutral;

[0031] e) Infrared drying the precipitate at 90-100°C for 3-10 hours to obtain nano-zinc ferrite (ZnFe 2 o 4 )Precursor;

[0032] f) Naturally cool the precursor to room temperature, grind it into powder, and then impregnate it in 0.75mol / L (NH 4 ) 2 S 2 o 8 In the solution, after soaking for 10 hours, filter, and dry the obtained solid at 110°C for 6 hours;

[0033] g) Roasting at 500K for 3 hours, annealin...

Embodiment 2

[0040] a) press n (Fe 2+ ):n(Zn 2+ )=1.8:1 Weigh FeSO 4 ·7H 2 O and ZnSO 4 ·7H 2 O, mixed and ground into powder;

[0041] b) According to n(NaOH):n(Fe 2+ )=1.6:1 Add NaOH solution, and press n(PEG):n(Fe 2+ )=0.02:1 Add the dispersant polyethylene glycol (PEG-600), and stir at 50-70°C for 30-60 minutes;

[0042] c) Press n (NaHCO 3 ):n(Fe 2+ )=1.8:1 adding NaHCO 3 Solid, adjust pH=11, stir at 50-70°C for 10-20 minutes;

[0043] d) Aging at 20-40°C for 7 hours, suction filtering, and washing the obtained precipitate with absolute ethanol until neutral;

[0044] e) Infrared drying the precipitate at 90-100°C for 3-10 hours to obtain nano-zinc ferrite (ZnFe 2 o 4 )Precursor;

[0045] f) The precursor is naturally cooled to room temperature, ground into powder, and then impregnated in 1.2mol / L (NH 4 ) 2 S 2 o 8 In the solution, filter after soaking for 6 hours, and dry the obtained solid at 100°C for 8 hours;

[0046] g) Roasting at 550K for 3 hours, annealing a...

Embodiment 3

[0053] a) press n (Fe 2+ ):n(Zn 2+ )=1.5:1 Weigh FeSO 4 ·7H 2 O and ZnSO 4 ·7H 2 O, mixed and ground into powder;

[0054] b) According to n(NaOH):n(Fe 2+ )=1.5:1 NaOH solution was added, and n(PEG):n(Fe 2+ )=0.06:1 Add the dispersant polyethylene glycol (PEG-600), and stir at 50-70°C for 30-60 minutes;

[0055] c) Press n (NaHCO 3 ):n(Fe 2+ )=1.7:1 adding NaHCO 3 Solid, adjust pH=8, stir at 50-70°C for 10-20 minutes;

[0056] d) Aging at 20-40°C for 3 hours, suction filtering, and washing the obtained precipitate with absolute ethanol until neutral;

[0057] e) Infrared drying the precipitate at 90-100°C for 3-10 hours to obtain nano-zinc ferrite (ZnFe 2 o 4 )Precursor;

[0058] f) The precursor is naturally cooled to room temperature, ground into powder, and then impregnated in 0.5mol / L (NH 4 ) 2 S 2 o 8 In the solution, after soaking for 12 hours, filter, and dry the obtained solid at 90°C for 10 hours by infrared;

[0059] g) Roasting at 450K for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com