Methods for oxidizing and degrading organic contaminants in water by utilizing multiphase catalyst to strengthen Fenton technology

A heterogeneous catalyst and organic pollutant technology, applied in the fields of oxidation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve incomplete oxidation degradation, low efficiency, consumption of hydroxyl radicals, etc. problems, to achieve high recycling efficiency, improve processing efficiency, and not easy to consume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

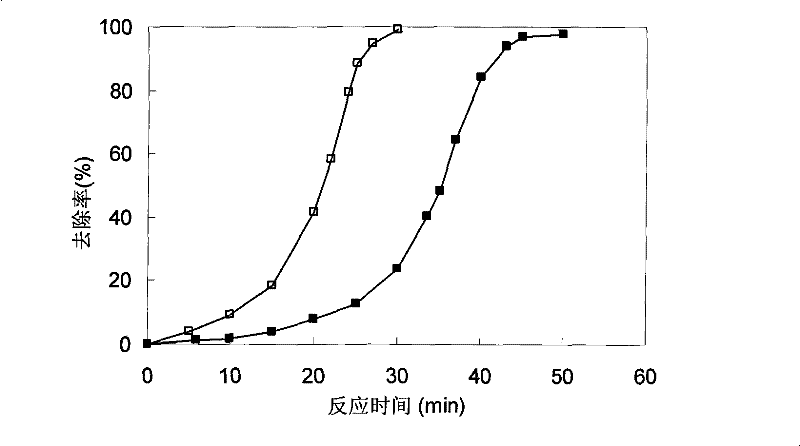

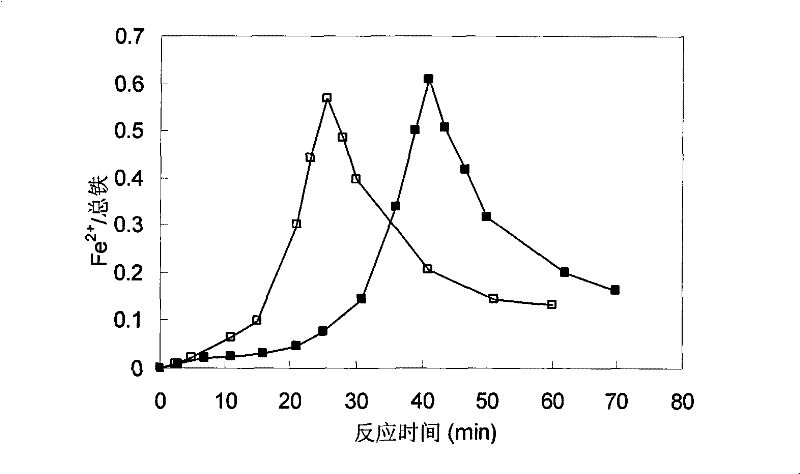

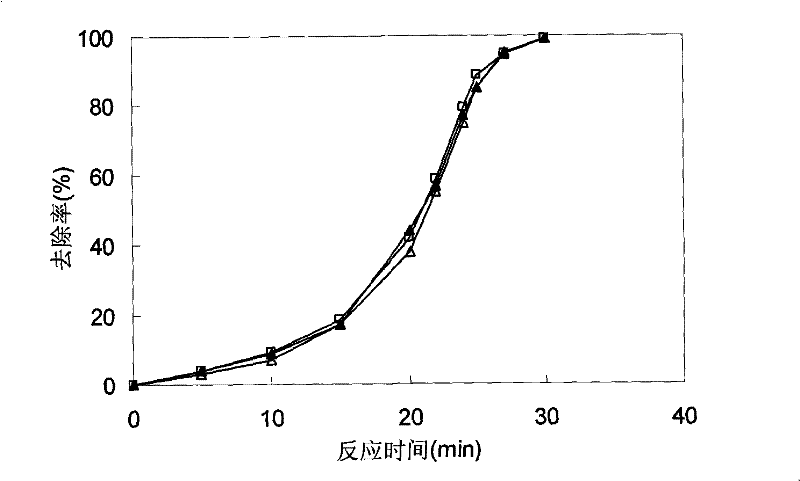

[0011] Specific embodiment one: this embodiment utilizes heterogeneous catalyst to strengthen the method for oxidative degradation of organic pollutants in water by Fenton process to carry out according to the following steps: 1. Pretreatment: the water containing organic pollutants is carried out through grille, sedimentation tank and adjustment tank Physical treatment, control the hydraulic retention time to 20-40 minutes; 2. Enter the pretreated water into the reactor filled with multi-phase catalyst, add iron ions and H 2 o 2 Solution, control the concentration of iron ions in the reactor to be 0.2-20mg / L, H 2 o 2 The molar concentration ratio to iron ions is 5-10:1, and the residence time of water is 10-40 minutes; 3. The water treated in step 2 is discharged after solid-liquid separation; that is, the oxidative degradation of organic pollutants in water is completed ; Wherein the iron ion in the step 2 is Fe 2+ and / or Fe 3+ In step 2, the heterogeneous catalyst in th...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is: in step 1, the hydraulic retention time is controlled to be 25-35 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is: in step 1, the hydraulic retention time is controlled to be 30 minutes. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com