Water glass-triacetyl glycerine grouting material and preparation method thereof

A technology of glycerol triacetate and grouting materials, which is applied in the direction of soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of low strength of reinforced fine sand, unstable permeability, and groundwater pollution, and achieve anti- The effect of high compressive strength, strong permeability and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

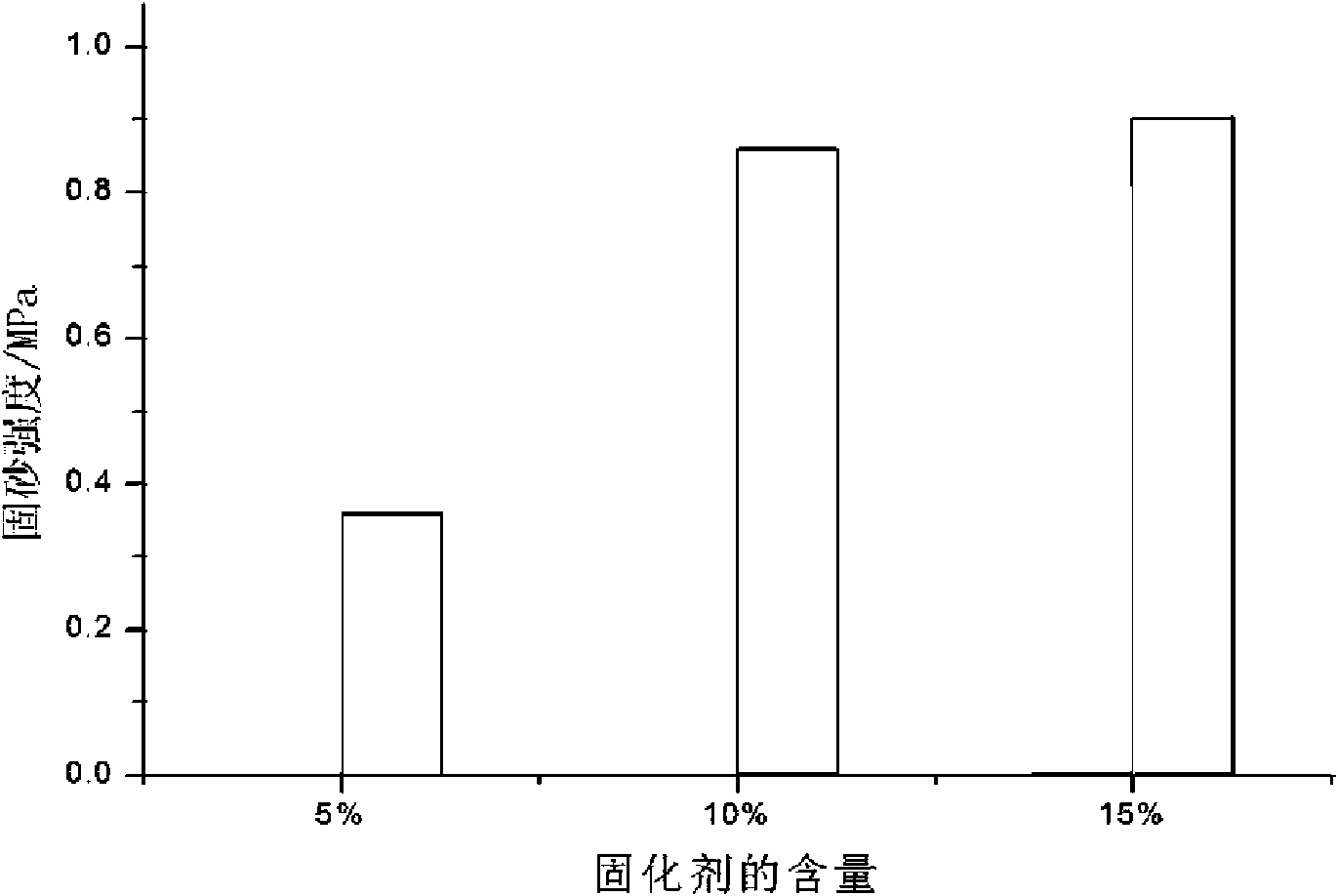

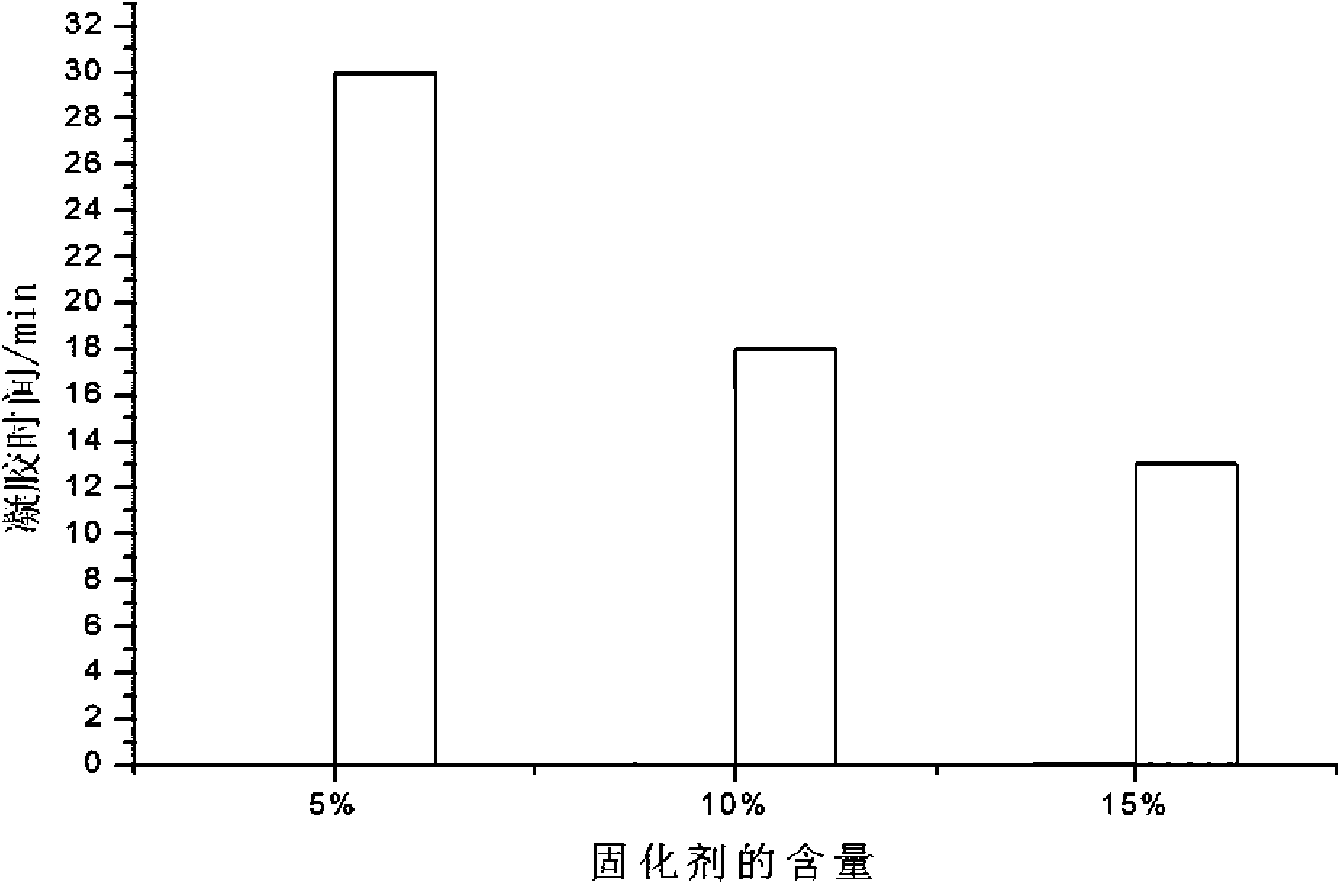

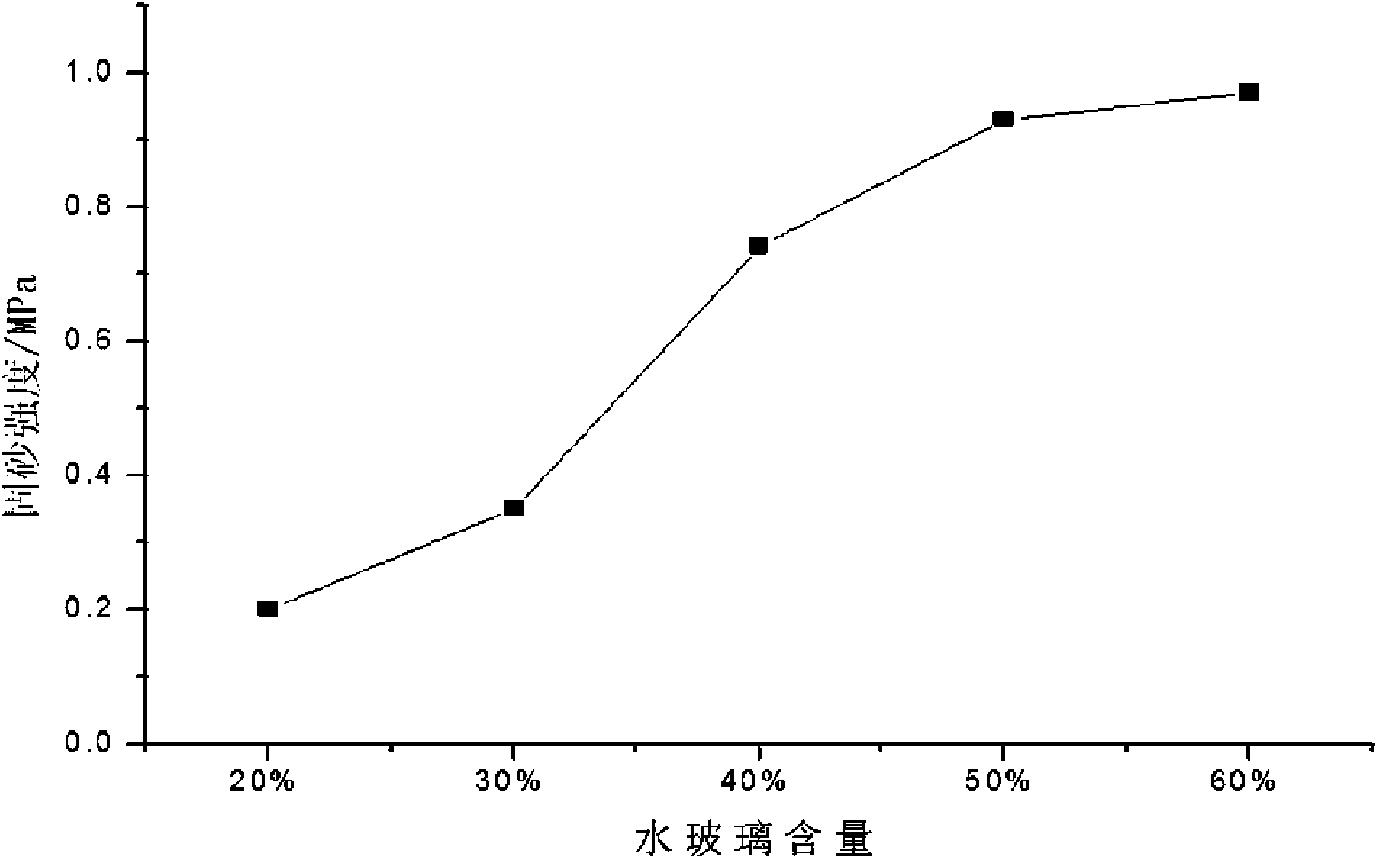

[0031] Embodiment 1, this reinforced powder fine sand water glass type grouting material, take water glass as the main material, take curing agent, catalyst, surfactant as auxiliary materials, and form according to the following parts by weight,

[0032] 100 parts of water;

[0033] 50 parts of water glass;

[0034] Glyceryl triacetate as 10 parts of curing agent;

[0035] Catalyst 0.1 part;

[0036] Surfactant 1 part.

[0037] Above-mentioned catalyst is acetic acid or dilute sulfuric acid, surfactant can be sodium dodecylbenzenesulfonate, and the modulus of water glass is 1.6~3.4, is preferably 2.8.

Embodiment 2

[0038] Embodiment 2, this reinforced powder fine sand water glass type grouting material, take water glass as the main material, take curing agent, catalyst, surfactant as auxiliary materials, and form according to the following parts by weight,

[0039] 100 parts of water;

[0040] 60 parts of water glass;

[0041] Glyceryl triacetate as 5 parts of curing agent;

[0042] Catalyst 0.2 part;

[0043] Surfactant 1.5 parts.

Embodiment 3

[0044] Embodiment 3, this reinforced powder fine sand water glass type grouting material is based on water glass, with curing agent, catalyst, and surfactant as auxiliary materials, and is formed by the following proportions by weight,

[0045] 100 parts of water;

[0046] 70 parts of water glass;

[0047] Glyceryl triacetate as 12 parts of curing agent;

[0048] Catalyst 0.3 part;

[0049] Surfactant 0.7 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com