Catalyzing distillation method for gasoline alkylate desulfuration

A technology of alkylation desulfurization and catalytic distillation, which is applied in hydrocarbon distillation, petroleum industry, refined hydrocarbon oil, etc. It can solve the problem of low conversion rate of thiophene and achieve the effects of easy control of the process, mild operating conditions, and accelerated reaction and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

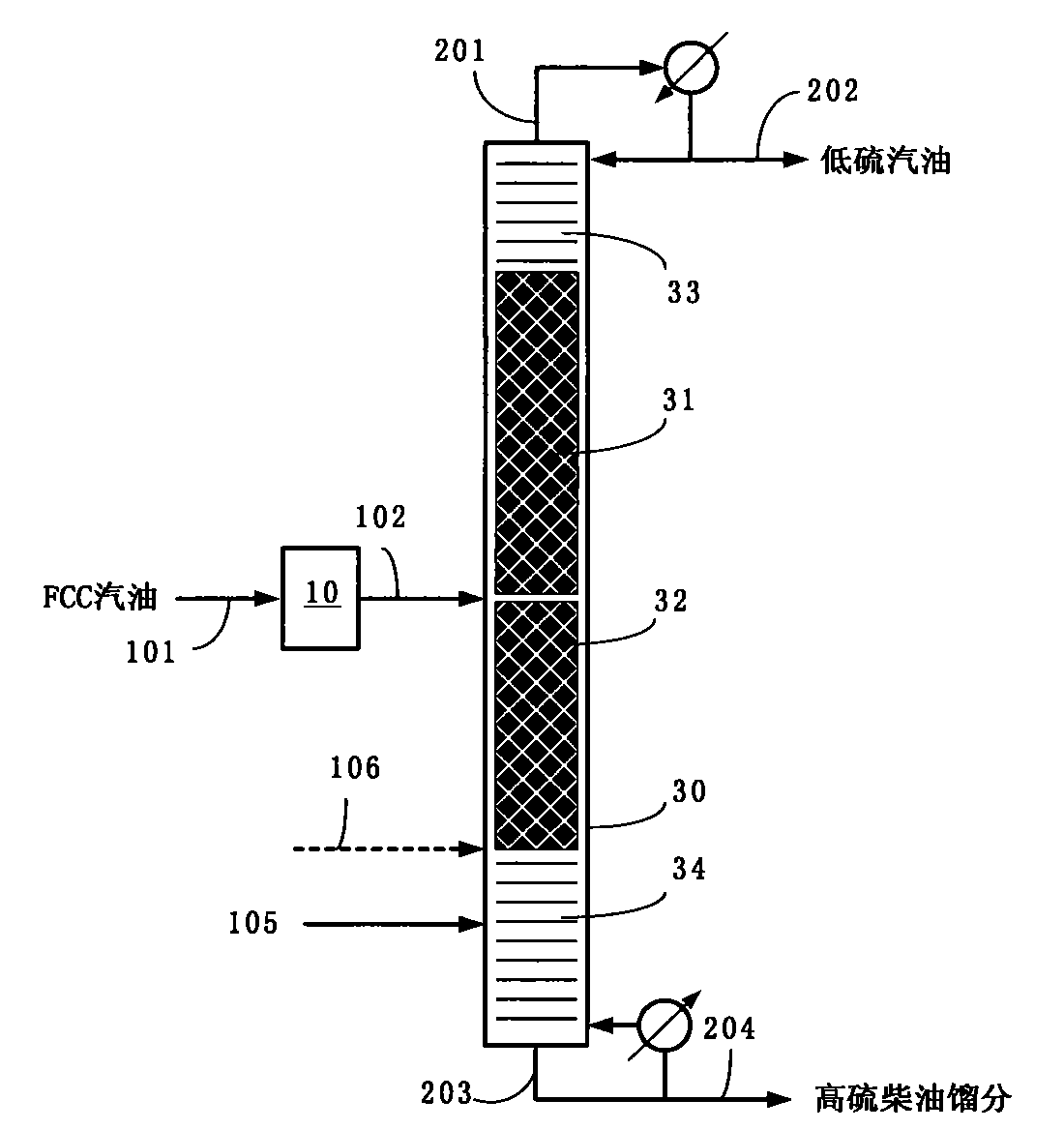

[0024] Combine figure 1 , The process of the present invention is further explained.

[0025] The catalytic distillation tower is divided into four parts: the upper reaction section 31, the lower reaction section 32, the rectification section 33 and the stripping section 34. The FCC gasoline feedstock is connected to the preconditioner 10 through the pipeline 101, and then connected between the upper reaction section 31 and the lower reaction section 32 of the catalytic distillation tower 30 through the pipeline 102, and the pipeline 106 for supplementing C3-C5 olefins and the bottom of the lower reaction section 32 In connection, the diesel or high boiling point hydrocarbon oil pipeline 105 is connected to the stripping section 34 of the catalytic distillation column 30. The top steam is connected to the total condenser through a pipe 201, and the pipe 202 is connected to the distillate outlet of the catalytic distillation column 30. The pipes 203 and 204 are ...

Example Embodiment

[0028] Example 2

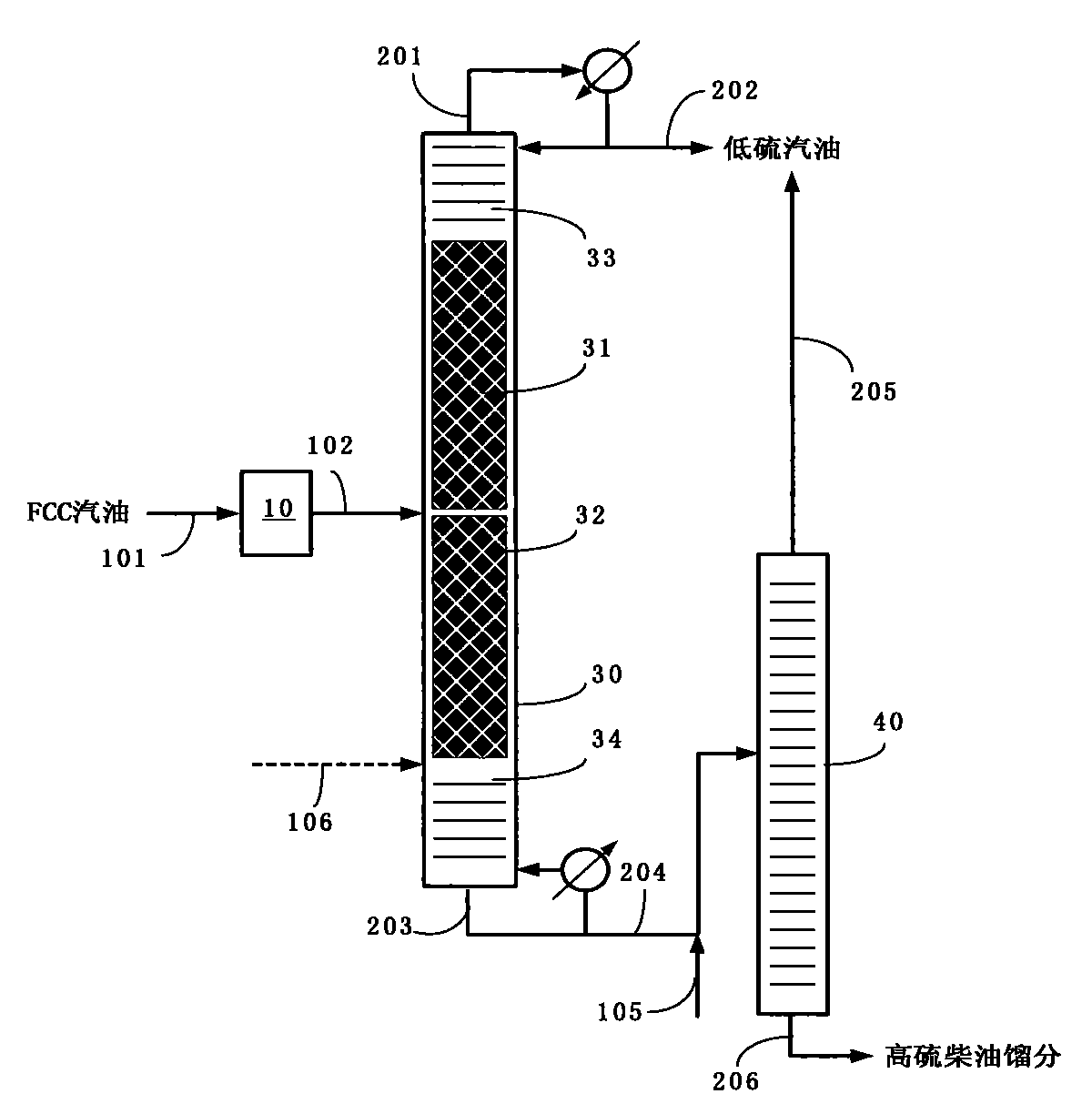

[0029] Knot and attach figure 2 , The process of the present invention is further explained.

[0030] The catalytic distillation tower is divided into four parts: the upper reaction section 31, the lower reaction section 32, the rectification section 33 and the stripping section 34. The FCC gasoline feedstock is connected to the preconditioner 10 through the pipeline 101, and then connected between the upper reaction section 31 and the lower reaction section 32 of the catalytic distillation tower 30 through the pipeline 102, and the pipeline 106 for supplementing C3-C5 olefins and the bottom of the lower reaction section 32 connection. The top steam is connected to the total condenser through a pipe 201, and the pipe 202 is connected to the distillate outlet of the catalytic distillation column 30. The bottom of the catalytic distillation tower 30 is connected to the middle of the fractionation tower 40 through pipelines 203 and 204 after being merged with the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap