Axle-system axial pulsating force measurement device

A technology of measuring devices and pulsating force, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as lack of accurate input, lack of propellers, difficult propeller axial pulsation force parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

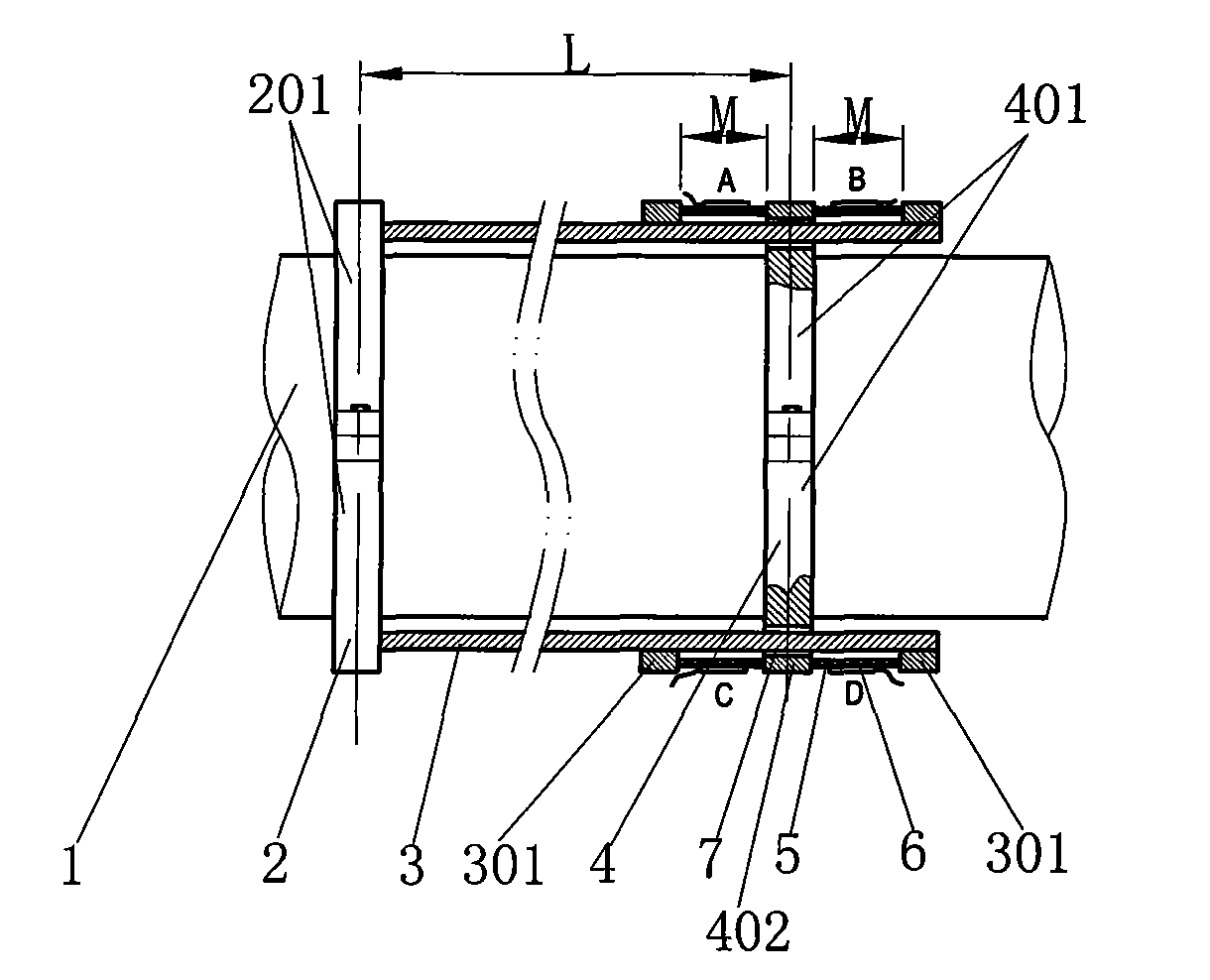

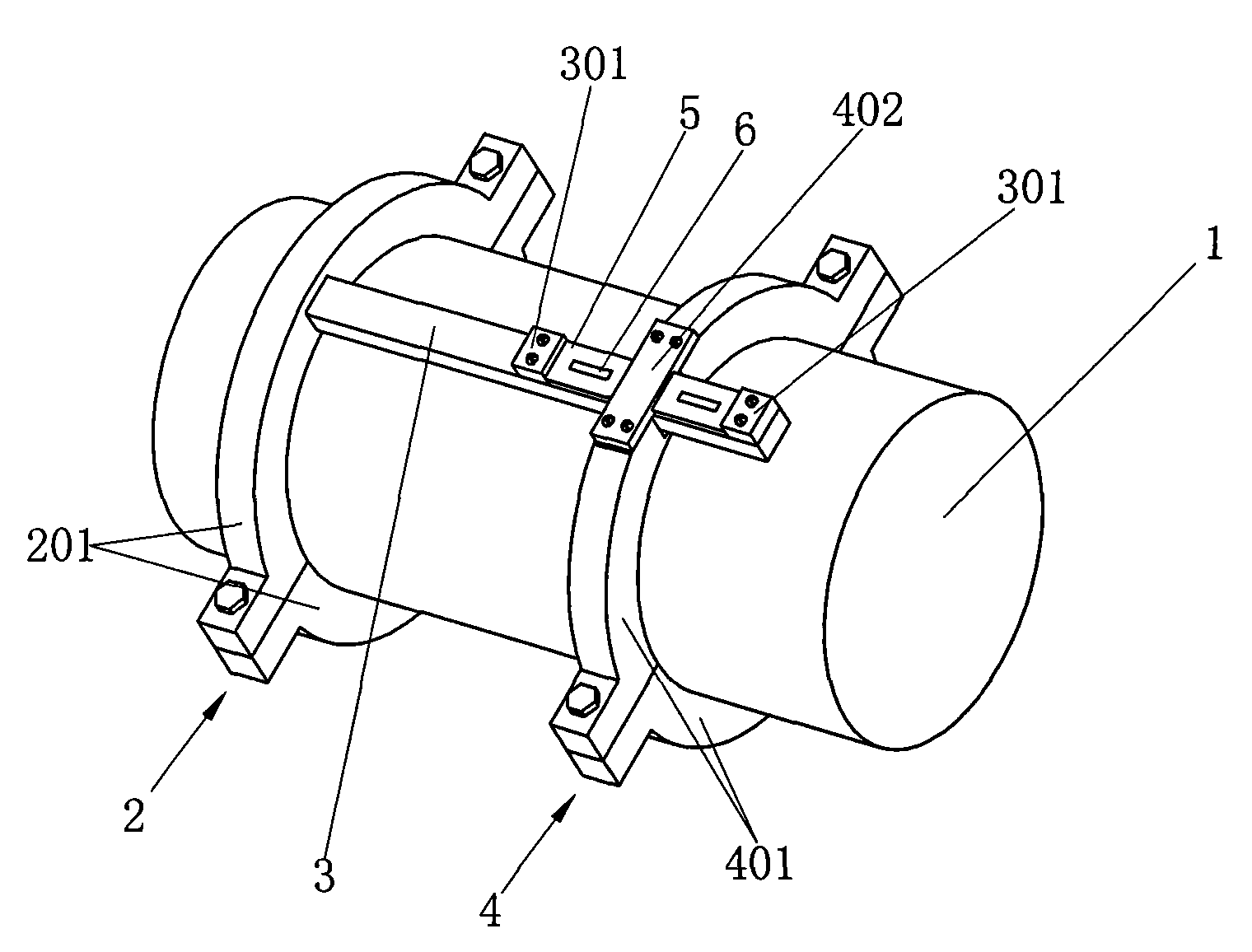

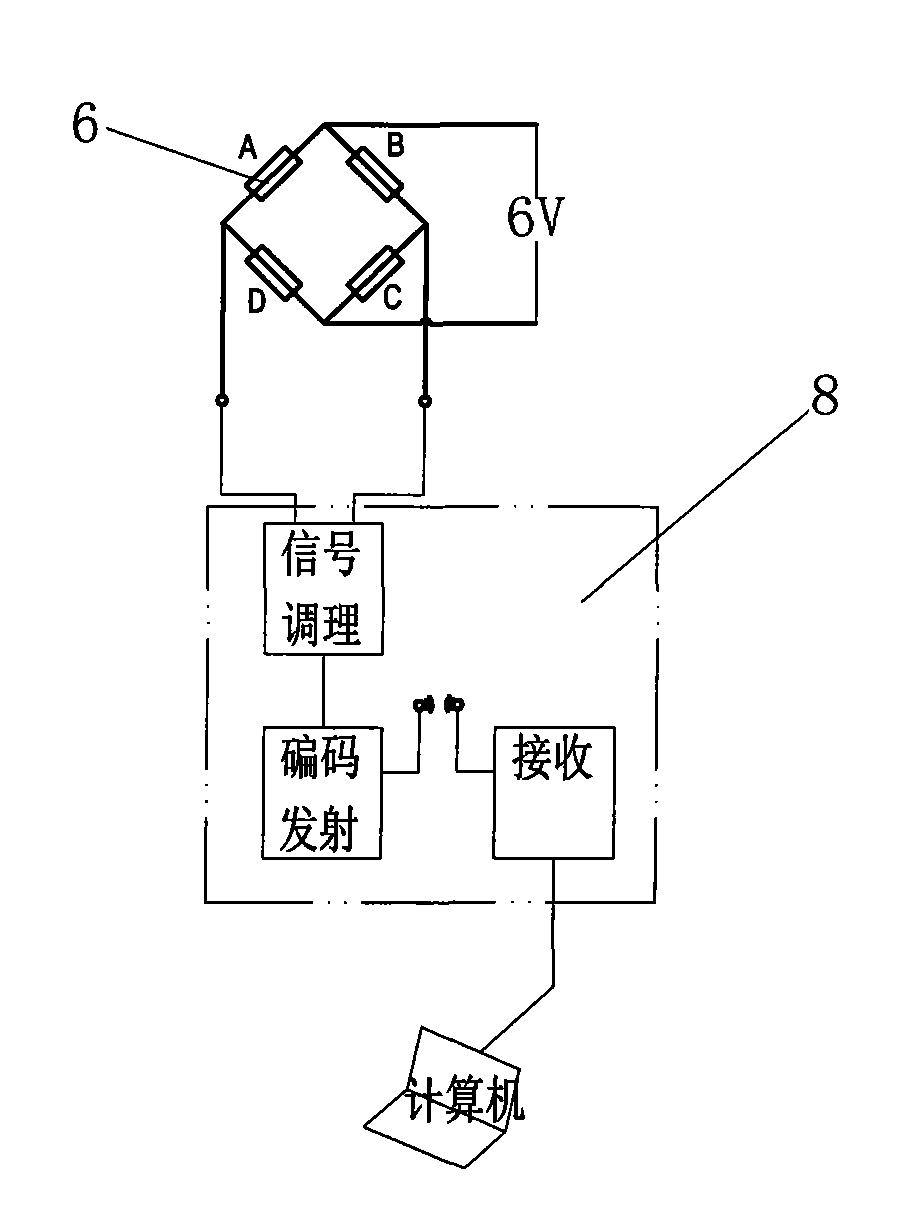

[0019] Such as figure 1 , 2 As shown, the present invention includes a first positioning flange 2 and a second positioning flange 4, and the first positioning flange 2 and the second positioning flange 4 are fixedly installed on the shaft 1 at a certain distance. The two dowel bars 3 are arranged symmetrically, and are respectively slidingly sleeved in the chute 7 of the second positioning flange 4. One ends of the two dowel bars 3 are respectively welded on the first positioning flange 2. In this embodiment, The first positioning flange 2 is composed of two semi-circular flanges 201 connected, and the two semi-circular flanges 201 are fixedly connected by screws and sleeved on the shaft 1; the second positioning flange 4 is composed of two sliding grooves 7 The semi-circular flanges 401 are connected, and the two semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com