Light-transmitting electric conductor, method of manufacturing the same, destaticizing sheet, and electronic device

A technology for electronic devices and electric conductors, applied in cable/conductor manufacturing, static electricity, transparent dielectrics, etc., can solve the problems of difficulty in using carbon nanotubes for conductivity, reduced transparency, and difficult to disperse carbon nanotubes, etc., and achieve high visible light transmittance , conductivity and mechanical properties are not damaged by the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In Embodiment 1, an example of a light-transmitting conductor and a method of manufacturing the light-transmitting conductor will mainly be described. In this case, it is assumed that carbon nanotubes are used as carbon nanolinear structures.

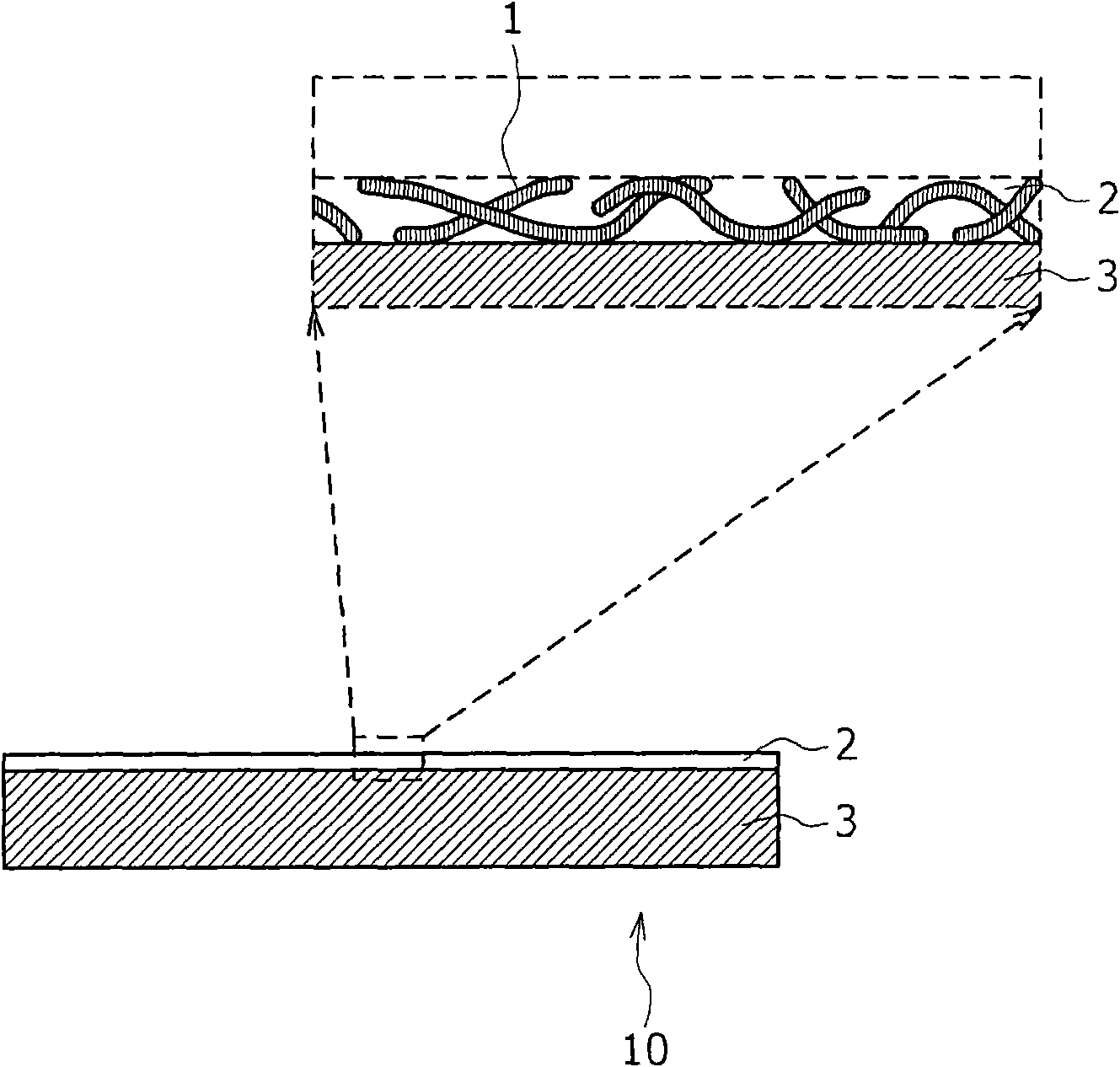

[0050] figure 1 A cross-sectional view illustrating the structure of the light-transmitting conductor 10 according to Embodiment 1 of the present invention and a partially enlarged cross-sectional view are shown. Such as figure 1 As shown, in the light-transmitting conductor 10, a conductive material 2 is provided directly on the main surface of the light-transmitting support 3 side, and a plurality of carbon nanotubes 1 are stacked two-dimensionally in the conductive material 2, and a plurality of carbon nanotubes The tubes 1 are in local contact with each other. The conductive material 2 has a structure in which carbon nanotubes 1 are stacked substantially two-dimensionally, and usually one or no carbon nanotubes 1 exist in ...

Embodiment 2

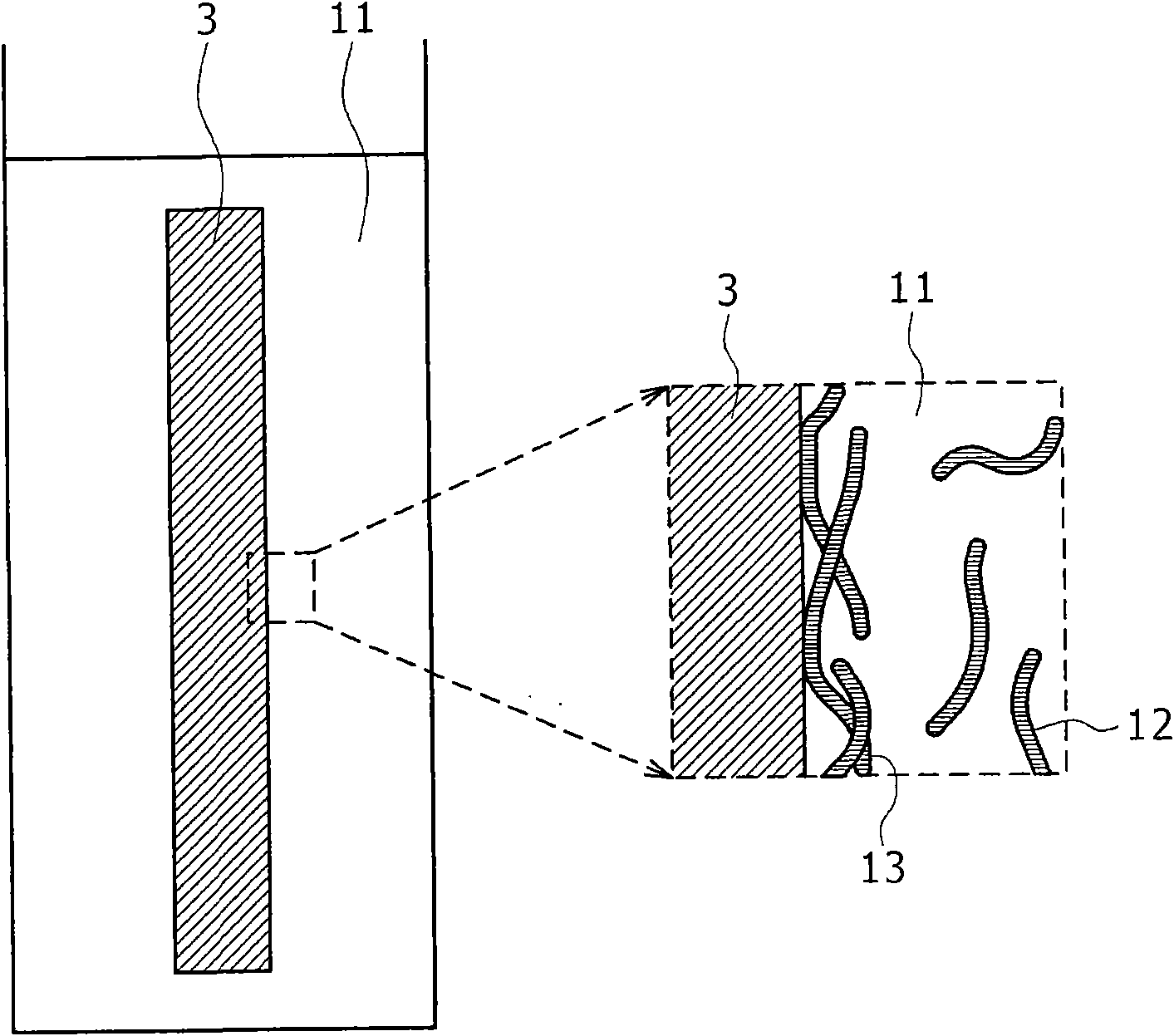

[0069]In Embodiment 2, another light-transmitting conductor and a method of manufacturing another light-transmitting conductor will be mainly described.

[0070] image 3 A cross-sectional view illustrating the structure of the light-transmitting conductor 20 according to Embodiment 2 of the present invention and a partially enlarged cross-sectional view are shown. Such as image 3 As shown, in the light-transmitting conductor 20, the conductive material 2 is provided to consist of carbon nanotubes 1 fixed to the main surface of one side of the light-transmitting support 3, and the polymer resin layer 21 is provided to cover the light-transmitting support 3 The junction between the surface of the surface and the carbon nanotube 1 in contact with the surface.

[0071] The polymeric resin layer 21 is a resin layer similar to the urethane acrylate resin described in Example 2 of Patent Document 2. For example, after the conductive material 2 consisting only of carbon nanotubes...

Embodiment 3

[0073] In Embodiment 3, as an example of an electronic device provided with a light-transmitting conductor, an electronic device configured as a touch panel is mainly described.

[0074] Figure 4 is a sectional view showing the structure of the touch panel 50 according to Embodiment 3 of the present invention. The touch panel 50 is a resistive film type touch panel in which a light-transmitting conductor 30 having a transparent conductive film 32 is provided on a light-transmitting support 31 and a light-transmitting conductor 40 having a transparent conductive film 42 is provided on a light-transmitting support 41 , the light-transmitting conductor 30 and the light-transmitting conductor 40 are arranged such that the transparent conductive film 32 and the transparent conductive film 42 face each other.

[0075] For example, the light-transmitting support 31 is a glass substrate, and the light-transmitting support 41 is a transparent polymer resin film such as a PET film. B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com