Zero gas consumption low dew point compression heat regeneration absorption compressed air drying method and device thereof

A technology of compressed air and drying method, which is applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., to achieve the effects of improving regeneration effect, low noise, and eliminating consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

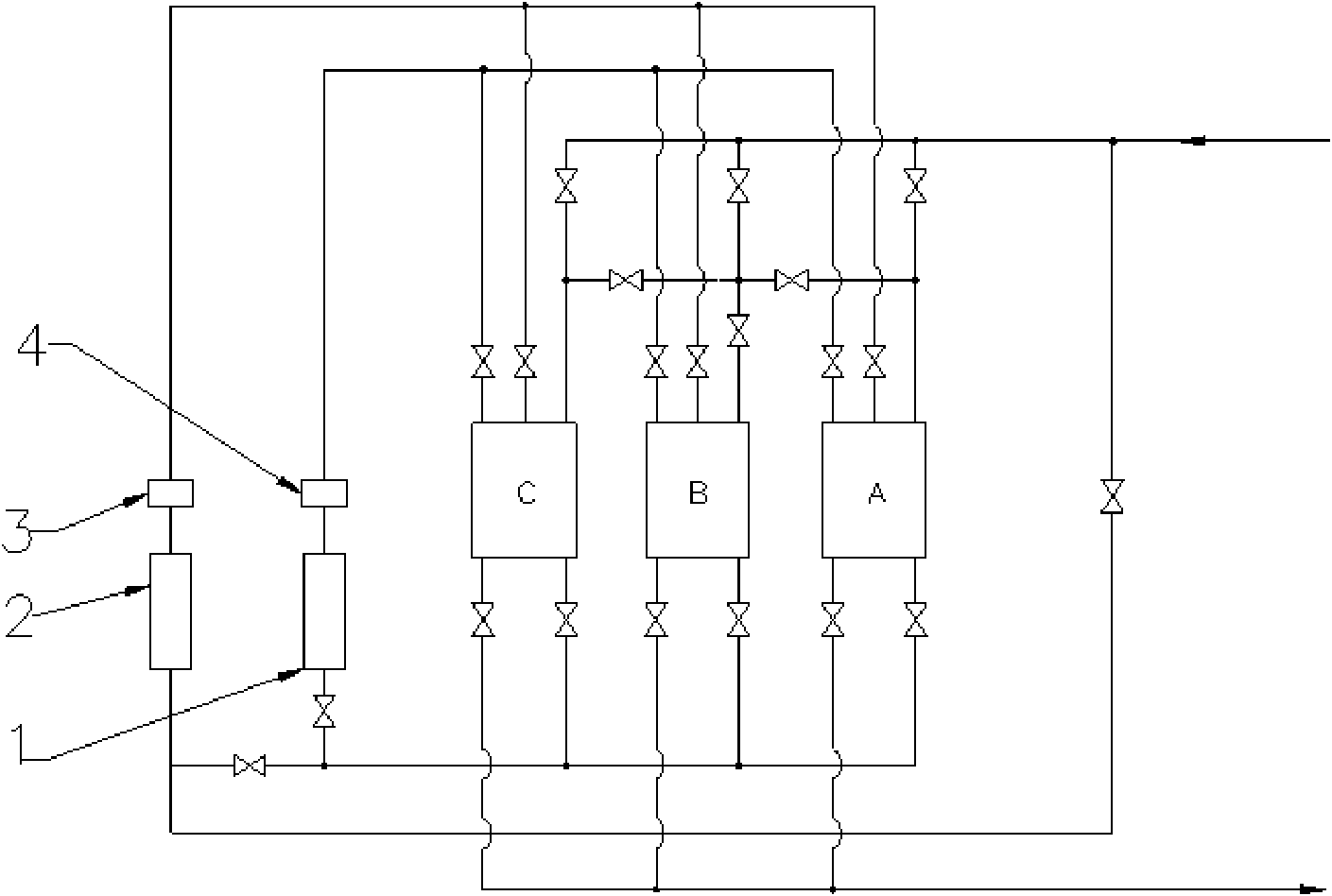

[0041] Example: attached figure 1It is a structural representation of the present invention. Including the adsorption and regeneration process carried out separately in different adsorption towers, the regeneration process includes heating and cold blowing process, characterized in that the method is carried out in three adsorption towers with the same adsorption capacity and the same specific heat of the adsorbent , the three adsorption towers are Tower A, Tower B, and Tower C, and the following steps a, b, and c are performed alternately:

[0042] a. When tower A is regenerated, tower B is the main adsorption, and tower C is the secondary adsorption

[0043] Tower A is heated, and tower B is adsorbing at this time, and the flow direction of its compressed air is as follows:

[0044] High temperature compressed air inlet-tower A-cooling-tower B-product gas outlet,

[0045] Tower A is cold blowing, at this time tower B and tower C are adsorbing, and the flow sequence of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com