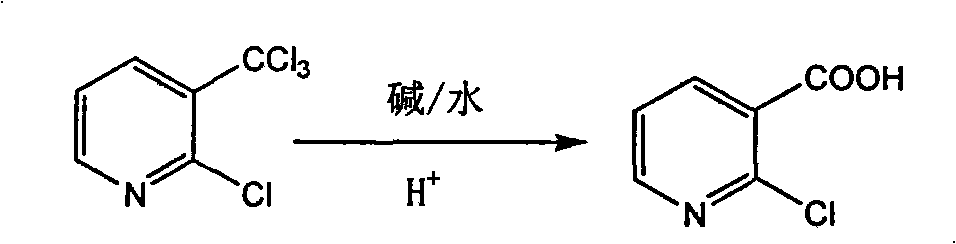

Novel method for synthesizing 2-chloronicotinic acid

A synthetic method, the technology of chloronicotinic acid, applied in the direction of organic chemistry, etc., can solve the problems of low yield and large amount of acid used, and achieve the effect of high yield, simple process and clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 10.0g (0.0433mol) of 2-chloro-3-trichloromethylpyridine, 100g of water, and 7.5g (0.1875mol) of sodium hydroxide were added to a 250ml four-neck flask, stirred and heated at 95°C for 4 hours, then stopped After the reaction, cool to room temperature, add concentrated hydrochloric acid to adjust the pH to below 1, there is a large amount of white precipitate, filter with suction, wash, and dry to obtain 6.46g of solid, 2-chloronicotinic acid with a purity of 97.9% and a yield of 92.8%.

Embodiment 2

[0024] 10.0g (0.0433mol) of 2-chloro-3-trichloromethylpyridine, 150g of water, 6.0g (0.15mol) of sodium hydroxide were added to a 250ml four-neck flask, stirred and heated at 50°C for 9 hours, then stopped After the reaction, cool to room temperature, add concentrated hydrochloric acid to adjust the pH to below 1, there is a large amount of white precipitate, filter, wash, and dry to obtain 6.42g of solid, 2-chloronicotinic acid with a purity of 95.2% and a yield of 89.6%.

Embodiment 3

[0026] 10.0g (0.0433mol) of 2-chloro-3-trichloromethylpyridine, 200g of water, and 8.5g (0.0802mol) of sodium carbonate were added to a 250ml four-neck flask, stirred and heated at 85°C for 6 hours, and the reaction was stopped After cooling to room temperature, concentrated hydrochloric acid was added to adjust the pH to below 1. There was a large amount of white precipitate, which was suction filtered, washed, and dried to obtain 6.50 g of solid. The purity of 2-chloronicotinic acid was 96.7%, and the yield was 92.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com