Needle selecting cam control device for flat knitting machine

A control device and triangle technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems that the needle selector cannot be reset, increase the noise, and weaken the driving force, etc., to achieve fast running speed, reliable and stable performance, and lighten the load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

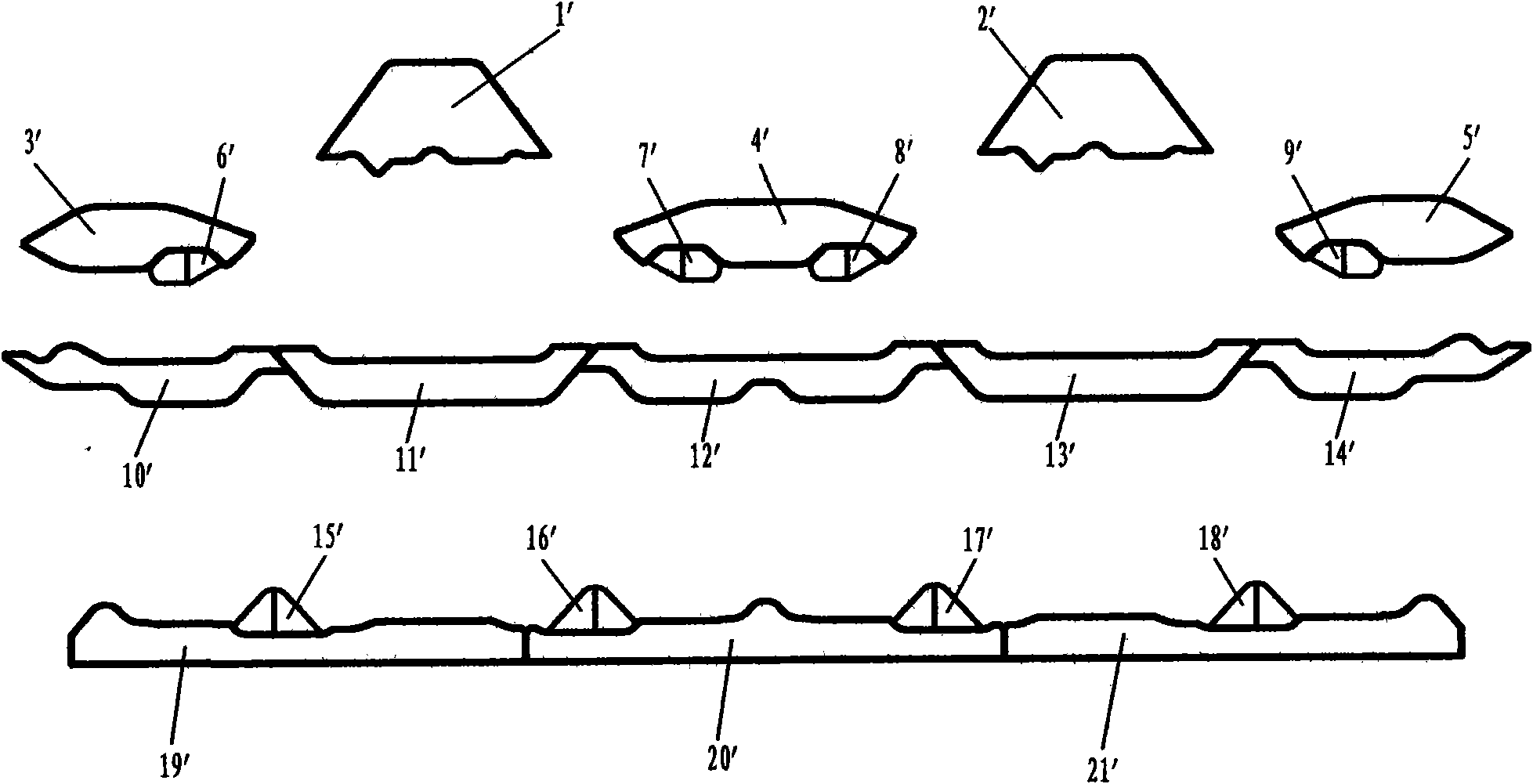

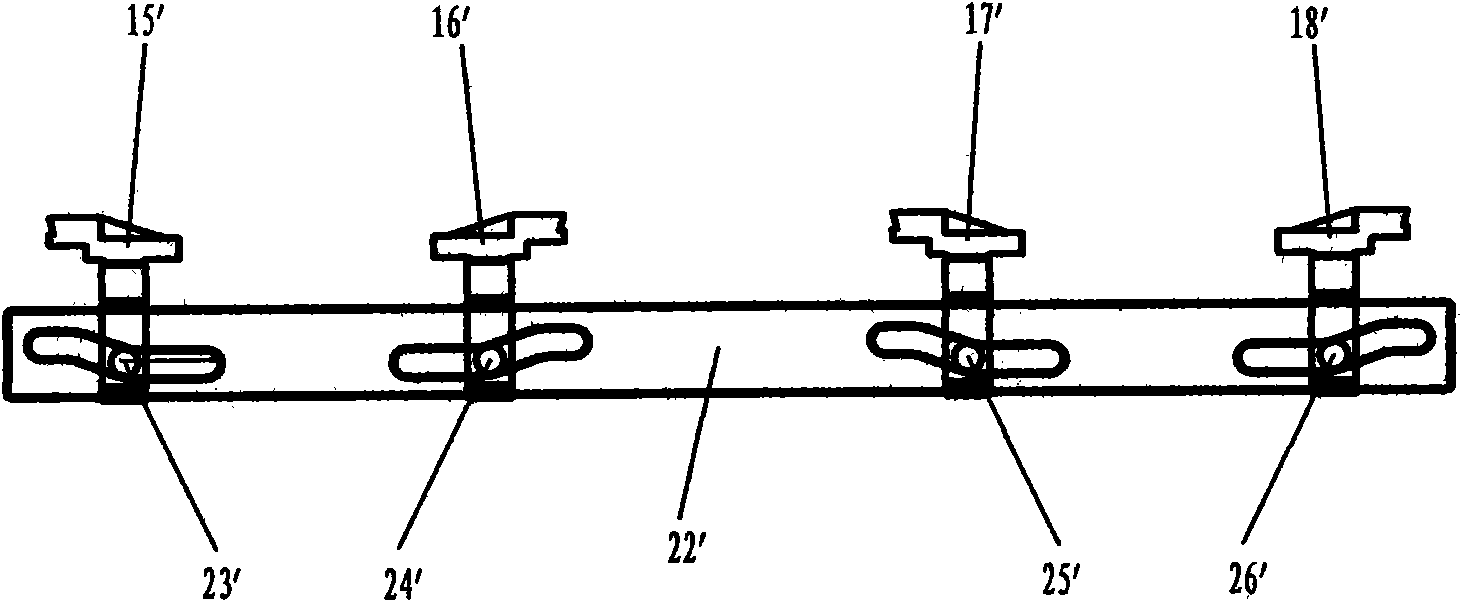

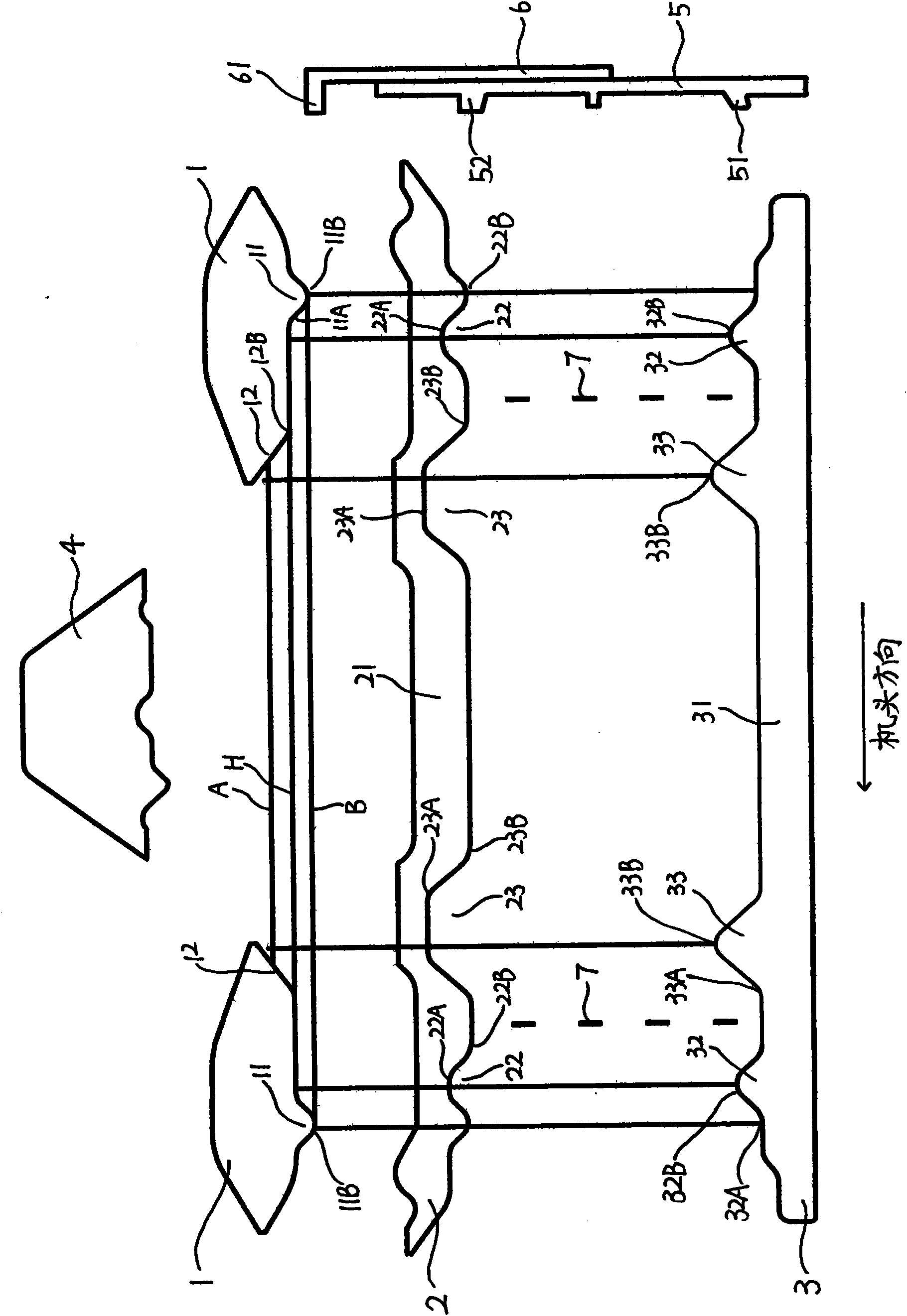

[0028] The needle selection cam control device of a flat knitting machine according to the present invention is arranged at the lower end of the flat knitting machine cam bottom plate relative to the knitting area, and controls a plurality of selector jacks 5 arranged together with knitting, and A plurality of needle presses 6 and each needle selection jack 5 have multiple bells, which can be moved up and down through the needle selection cam control device installed on the triangular bottom plate, so that the needle selection jacks can be adjusted according to the requirements of knitting with the cooperation of the needle selector. Needle selection.

[0029] The present invention includes at least one needle selection cam control unit (applied to one knitting cam in a single system), and may also include two or more needle selection cam control units (when the present invention is applied to two systems or multiple systems) , the following will take a unit as an example to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com