Device and method for testing inside relative humidity of cement base material

A technology of cement-based materials and testing devices, applied in the direction of material capacitance, etc., can solve the problems of restricting the depth of research, large gaps, and difficult sealing, etc., and achieve the effect of simple test methods, small device volume, and small test space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

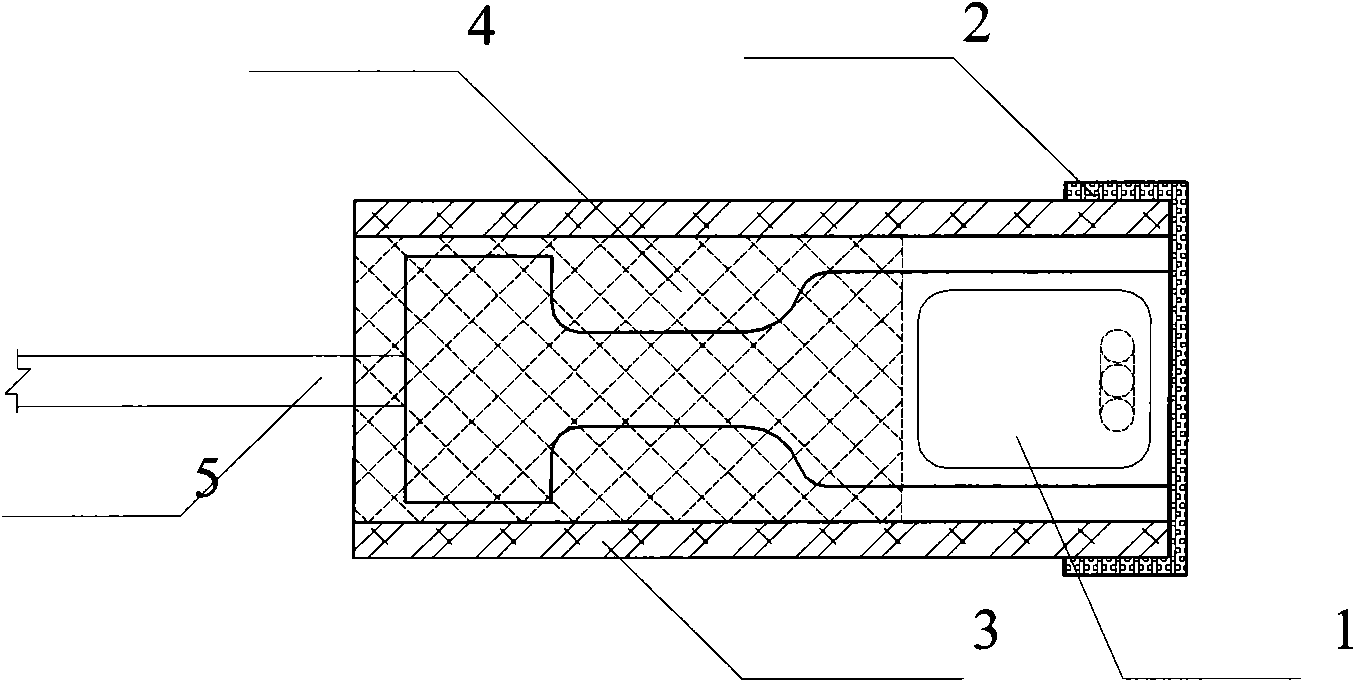

[0016] The humidity measuring element used in the embodiment of the present invention is a SHT75 digital temperature and humidity sensor, and the sensor includes a capacitive polymer humidity measuring element and an energy gap temperature measuring element. The main features of the sensor are: the humidity measurement accuracy is ±1.8%RH at 25°C, the temperature measurement accuracy is ±0.3°C; the humidity measurement range is 0 to 100%RH, and the temperature measurement range is -40 to +123.8°C; the response time is <8s; small size, etc.

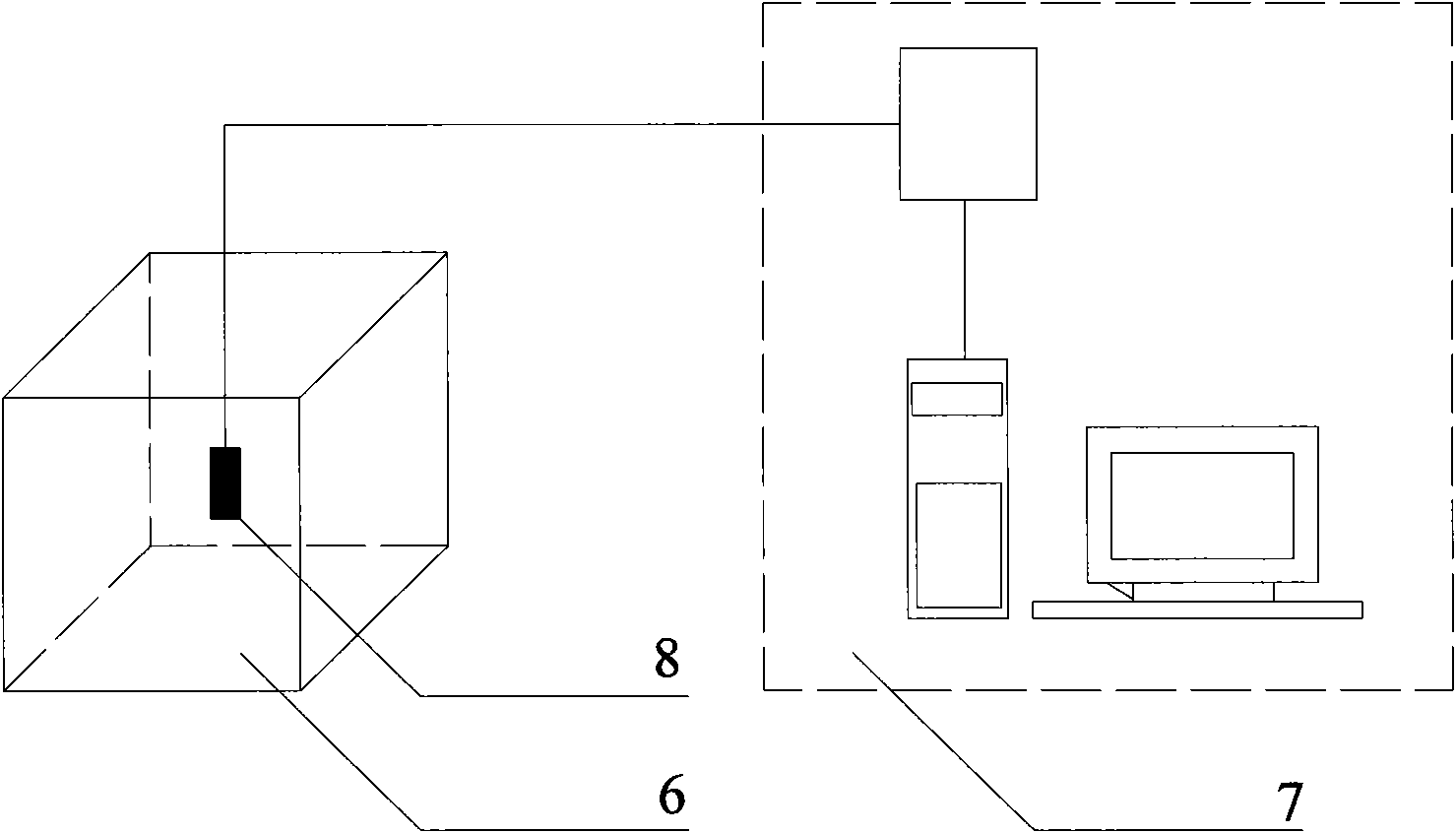

[0017] Embodiments of the present invention are introduced in conjunction with the accompanying drawings, accompanying drawings and embodiments:

[0018] The manufacturing method of the device of the present invention: first connect the SHT75 temperature and humidity sensor 1 with the four-core wire 5, and insert the casing 3 made of stainless steel. 32mm, so that the temperature and humidity sensor 1 is flush with the top of the casing 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com