Rotary tillage ditching stubble burying machine capable of rotating positively and reversely

A forward-reverse, rotary tiller technology, applied in the fields of tillage equipment, agricultural machinery and equipment, application, etc., can solve the problems of inconvenient adjustment of ditch width, affecting the leveling of fields and unadjustable width, etc., and achieve the functions of installation adjustment and change. Convenience, expand the scope of use, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiment is described in detail below in conjunction with accompanying drawing:

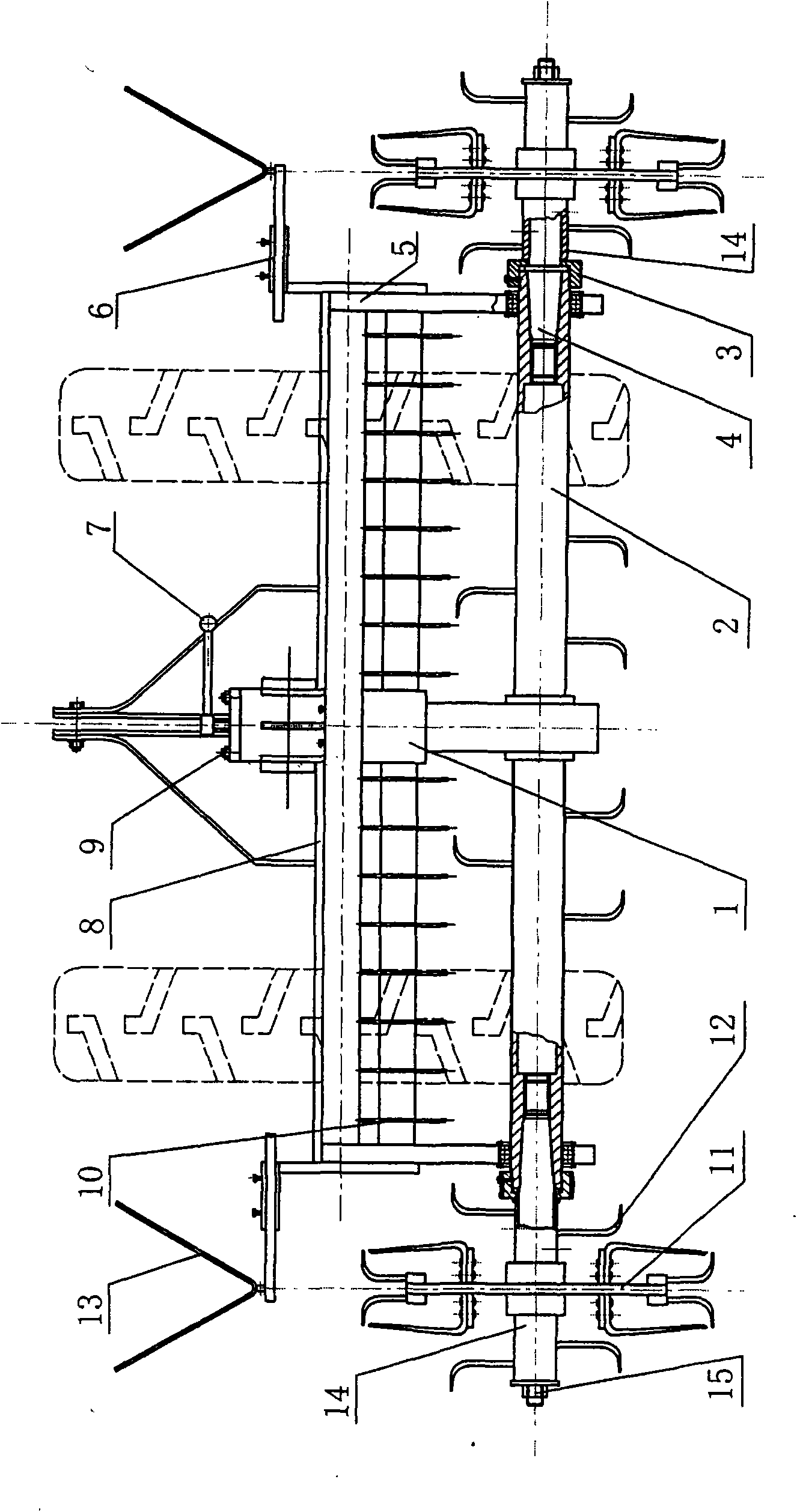

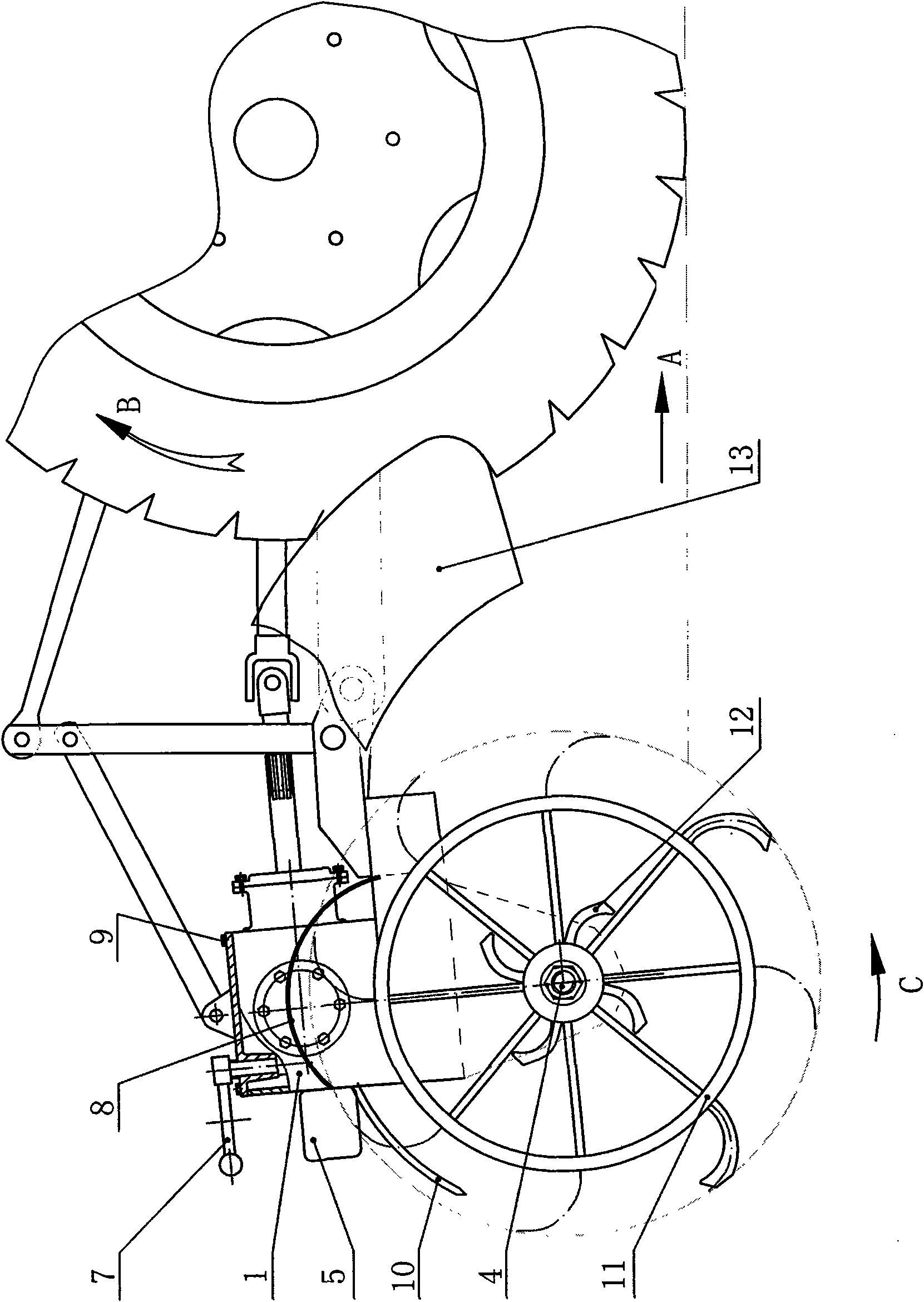

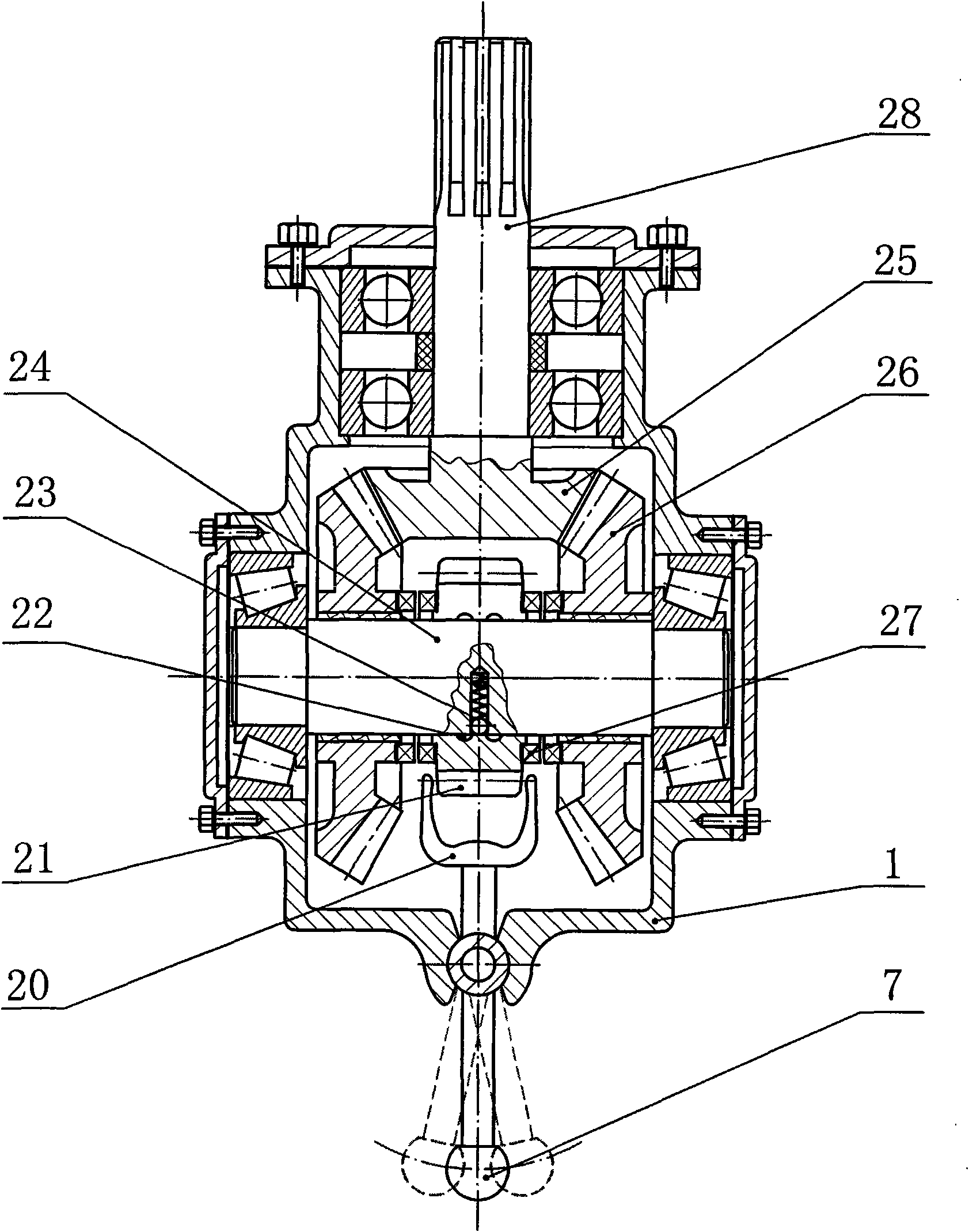

[0038] A reversible rotary tillage ditching and stubble embedding machine of the present invention, figure 1 It is the structure of Embodiment 1 shown from the rear view direction of the tractor: figure 1 Middle: 1. Reduction gear box, 2. Coulter shaft, 3. Set nut, 4. Cutter shaft, 5. Rotary cultivator frame, 6. Divider bracket, 7. Fork handle, 8. Vault Cover, 9, connecting bolt, 10, stubble fence, 11, ditching cutter head, 12, rotary tiller, 13, soil dividing plate, 14, leveling knife casing, 15, nut.

[0039] figure 1 A fork handle 7 is arranged on the upper part of the reduction gear box 1 of the rotary cultivator. The coulter shaft 2 is a circular tube structure, and the small conical end of its inner wall is provided with an internal spline. The cutter head shaft 4 is inserted into the coulter shaft 2. In the conical tube, the small conical end section is an external spline corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com