Method for increasing the activity of copper-based catalyst in water-gas shift reaction

A copper-based catalyst, a technology for shift reaction, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1~4

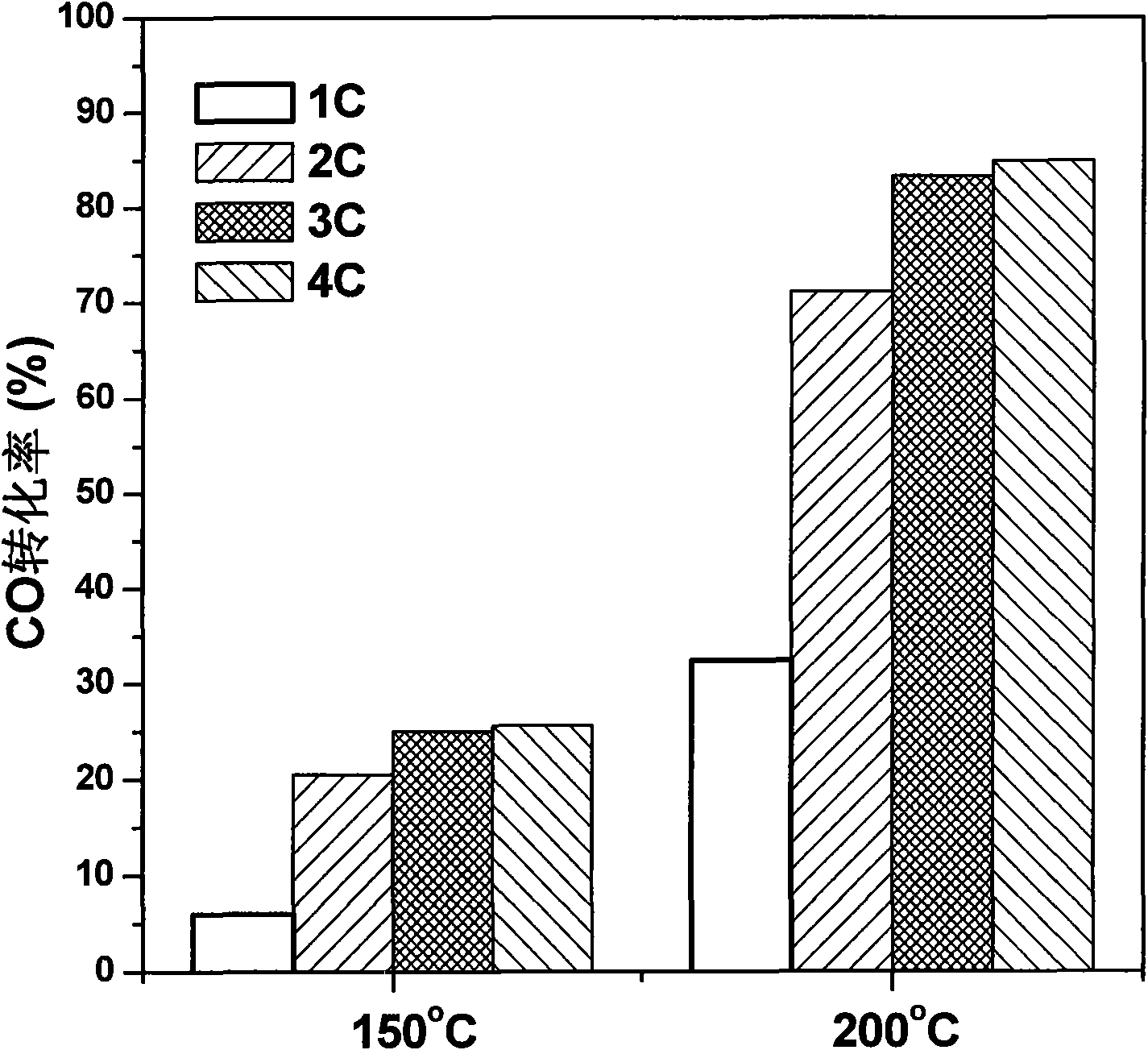

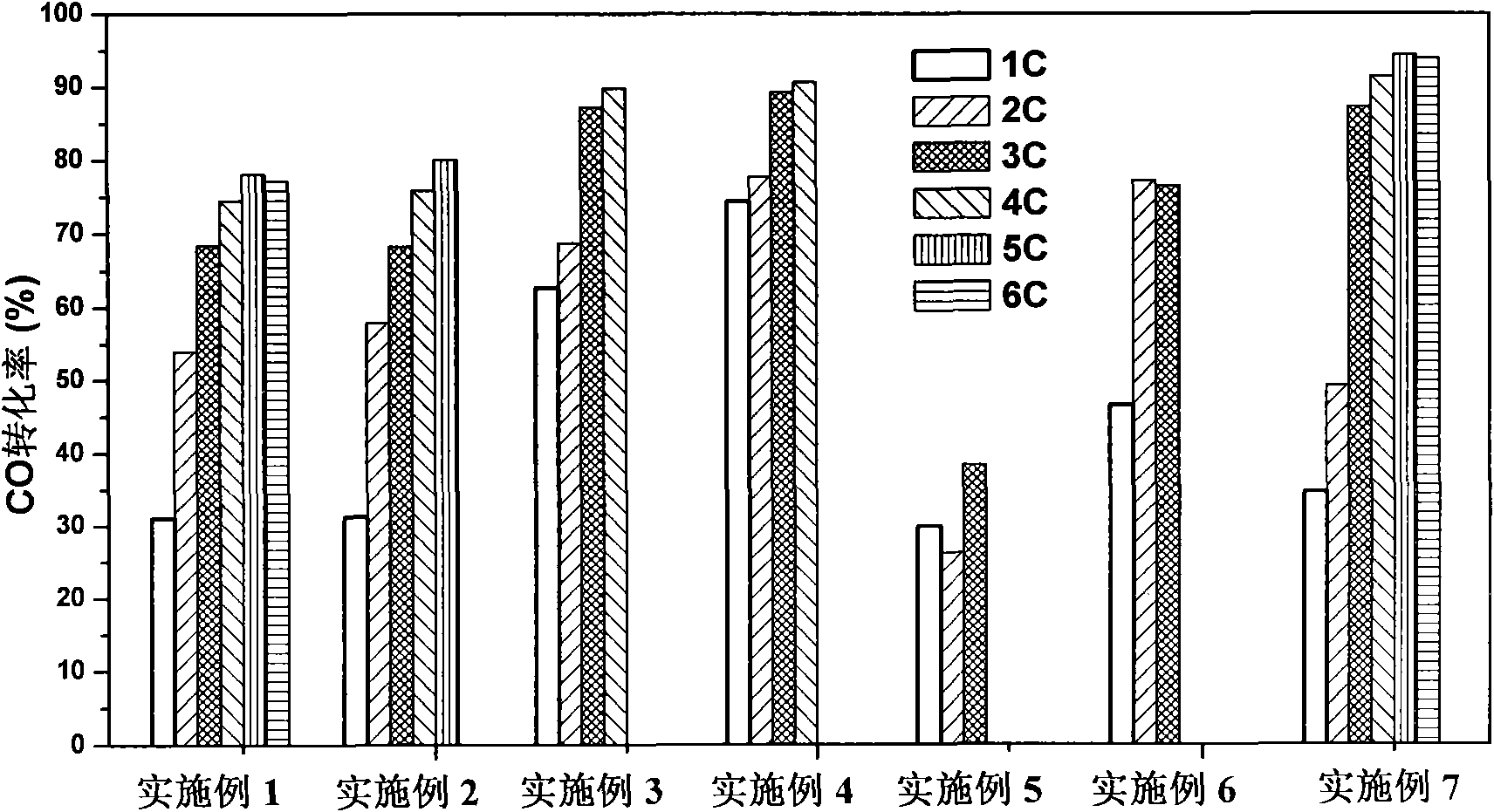

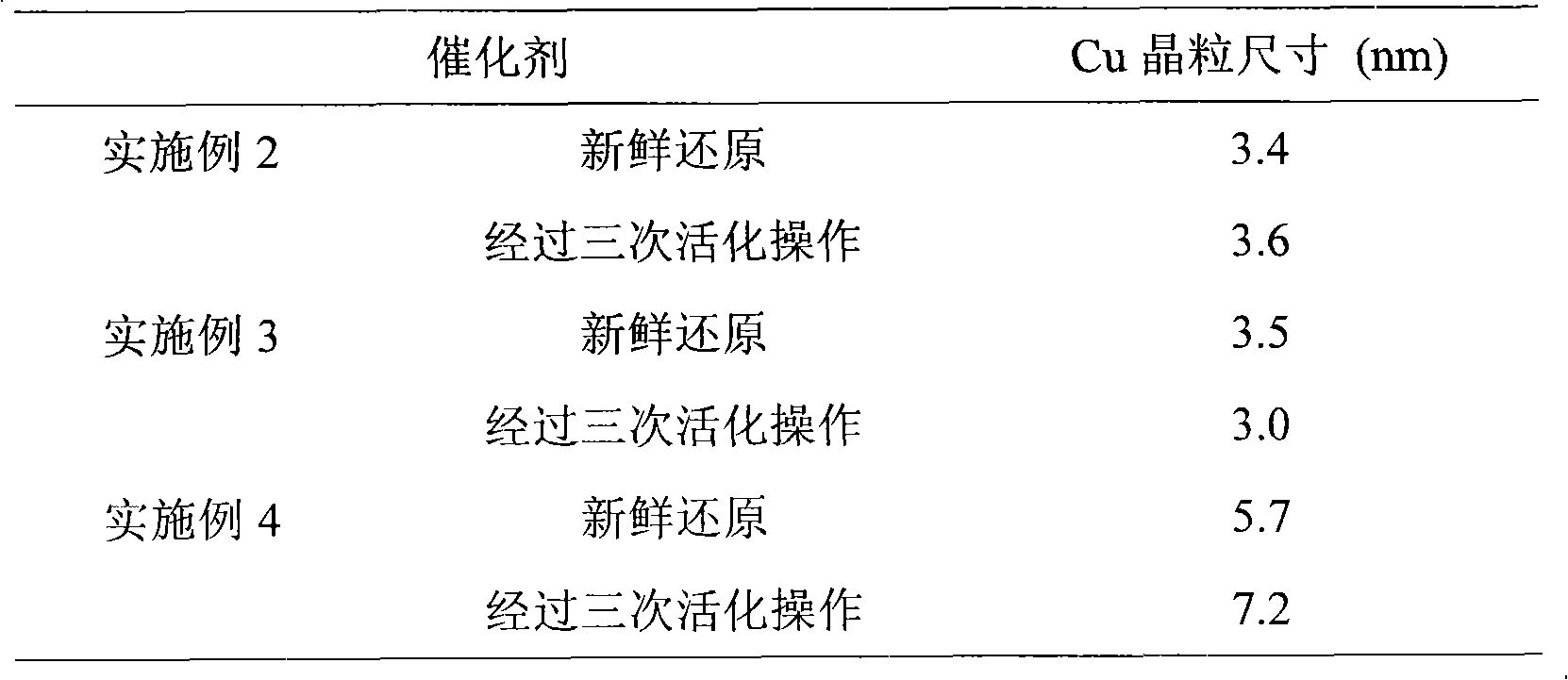

[0010] Add 6 grams of Cu(NO 3 ) 2 ·3H 2 O, 4.4 grams of Zn (NO 3 ) 2 ·6H 2 O, 28 grams of Al(NO 3 ) 3 ·9H 2 O and 19 grams of Mg(NO 3 ) 2 ·6H 2 O is dissolved in water to form a mixed solution of metal ions, 22 grams of Na 2 CO 3 Dissolve in water to obtain precipitant solution. Water bath at 60℃, stirring, while adding dropwise the metal ion and precipitant solution to mix the two together for co-precipitation. After the dripping is over, it is aged for 2 hours. The precipitate thus obtained needs to be washed to remove impurity ions, dried at 120°C overnight, and then calcined at 450, 500, 600, and 700°C for 4 hours to obtain catalyst examples 1 to 4, respectively.

preparation Embodiment 5

[0012] 3g Cu(NO 3 ) 2 ·3H 2 O, 17 grams of Al (NO 3 ) 3 ·9H 2 O and 12 grams of Mg(NO 3 ) 2 ·6H 2 O is dissolved in water to form a mixed solution of metal ions, 12 grams of Na 2 CO 3 Dissolve in water to obtain precipitant solution. Water bath at 60℃, stirring, while adding dropwise the metal ion and precipitant solution to mix the two together for co-precipitation. After the dripping is over, it is aged for 2 hours. The precipitate thus obtained also needs to be washed to remove impurity ions, dried at 120°C overnight, and then calcined at 600°C for 4 hours to obtain Catalyst Example 5.

preparation Embodiment 6

[0014] Add 8 grams of Cu(NO 3 ) 2 ·3H 2 O, 6.4 grams of Zn (NO 3 ) 2 ·6H 2 O, 5.4 grams of Al(NO 3 ) 3 ·9H 2 O is dissolved in water to form a mixed solution of metal ions, 8 grams of Na 2 CO 3 Dissolve in water to obtain precipitant solution. 70℃ water bath, stirring, while adding dropwise the metal ion and precipitant solution to mix the two together and co-precipitate. After the dripping is over, it is aged for 1 hour. The precipitate thus obtained needs to be washed to remove impurity ions, dried at 120°C overnight, and then calcined at 450°C for 4 hours to obtain Catalyst Example 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com