Method for processing wharf foundation by geotextile granular material pile

A technology of geotextiles and bulk piles, applied in the field of wharf foundation, can solve the problems of slow construction progress, high project cost, and secondary silting, and achieve the effects of speeding up construction progress, reducing dredging volume, and ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 (handling the pier foundation that foundation groove is arranged):

[0021] A method for treating dock foundations with geotextile bulk piles comprises the following steps:

[0022] 1) According to the water depth conditions at the front of the wharf, the foundation design does not require dredging;

[0023] 2) Lay out geotextile loose piles within the range not smaller than the length and width of the wharf foundation (within the range where the length is 0m longer than the wharf foundation and the width is 0m larger than the wharf foundation width) (see China Patent application number 200810197321.X, the name of the invention is: method for treating soft foundation with geotextile bulk piles); the planar pile method is quadrilateral, the pile diameter parameter of geotextile bulk piles is 60cm, and the distance between geotextile bulk piles is 1.8 m, the pile length of the geotextile loose pile is 3m, and the distance and pile length of the geotextile lo...

Embodiment 2

[0029] Embodiment 2 (handling the pier foundation that foundation groove is arranged):

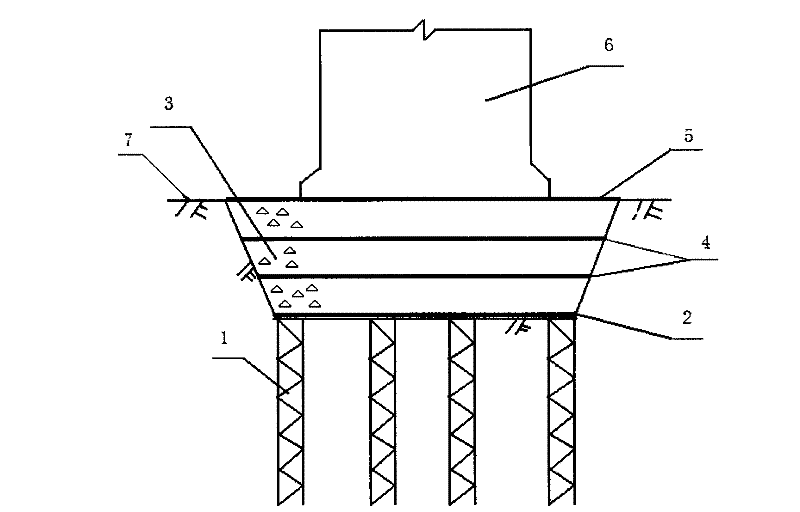

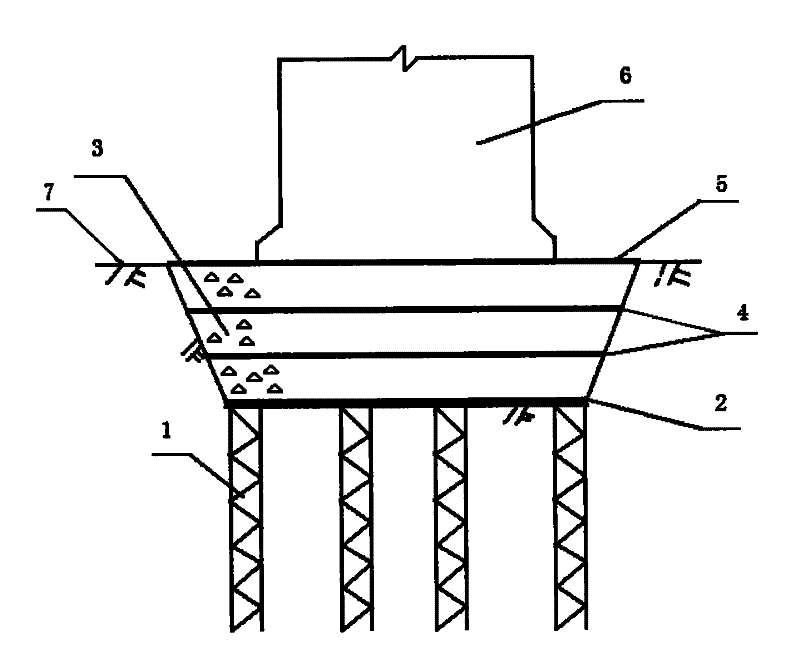

[0030] Such as figure 1 Shown, the method for processing dock foundation with geotextile bulk pile, it comprises the following steps:

[0031] 1) According to the water depth conditions at the front of the wharf, the foundation is designed to carry out shallow trench dredging, and the dredging depth of the foundation trench is 240cm;

[0032] 2) Lay out geotextile loose piles 1 within the range not smaller than the length and width of the wharf foundation (in the range where the length is 1m longer than the wharf foundation and the width is 1m wider than the wharf foundation) (for the construction method of the geotextile loose piles, see Chinese patent application number 200810197321.X, denomination of invention is: the method of geotextile bulk pile processing soft foundation); Plane pile mode is quadrilateral, the pile diameter parameter 100cm of geotextile bulk pile, the spacing of ge...

Embodiment 3

[0038] Embodiment 3 (processing the pier foundation that foundation groove is arranged):

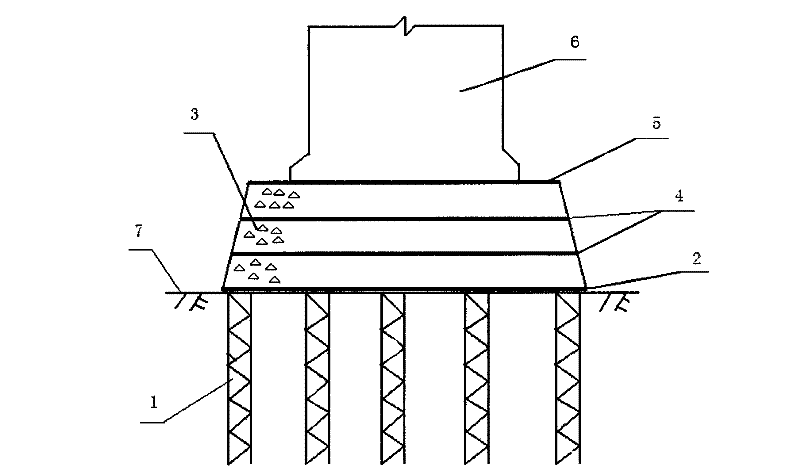

[0039] Such as figure 1 Shown, the method for processing dock foundation with geotextile bulk pile, it comprises the following steps:

[0040] 1) According to the water depth conditions at the front of the wharf, the foundation design shall be dredged in shallow trenches, and the dredging depth of the foundation trench shall be 50cm;

[0041] 2) Within the range not smaller than the length and width of the wharf foundation (within the range where the length is 3m longer than the wharf foundation and the width is 3m larger than the wharf foundation width), the geotextile loose pile 1 is laid out (for the construction method of the geotextile loose pile, see Chinese patent application number 200810197321.X, denomination of invention is: the method of geotextile bulk pile processing soft foundation); Plane pile mode is triangular, the pile diameter parameter 120cm of geotextile bulk pile, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com