Controllable wheel-groove slow flow type water turbine/water pump

A flow-type, water-wheel technology, applied in machines/engines, rotary piston pumps, rotary piston machines, etc., can solve the problems of not easy expansion, limited energy sources, power consumption, etc., to increase output power or Water flow, wide range of energy sources, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

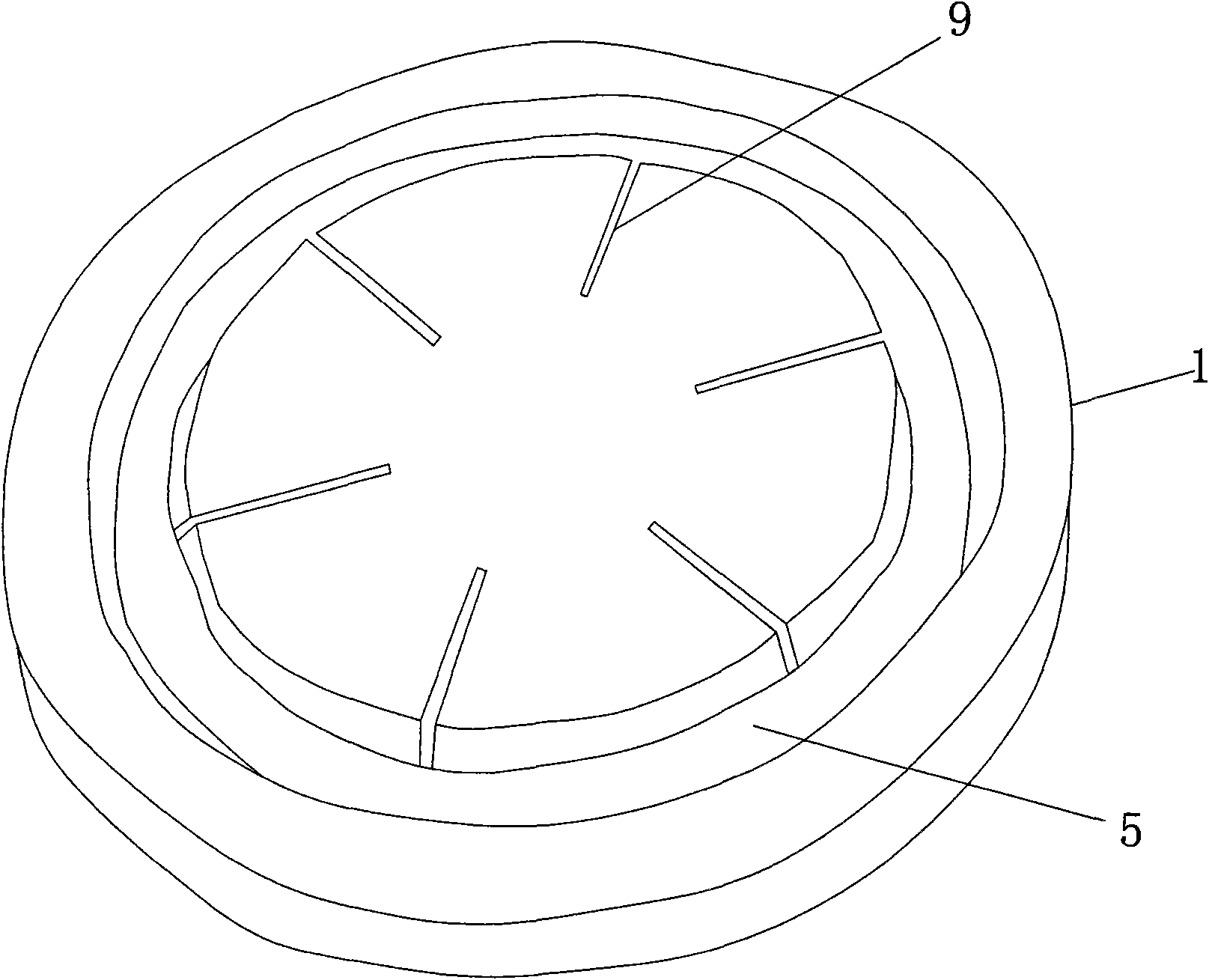

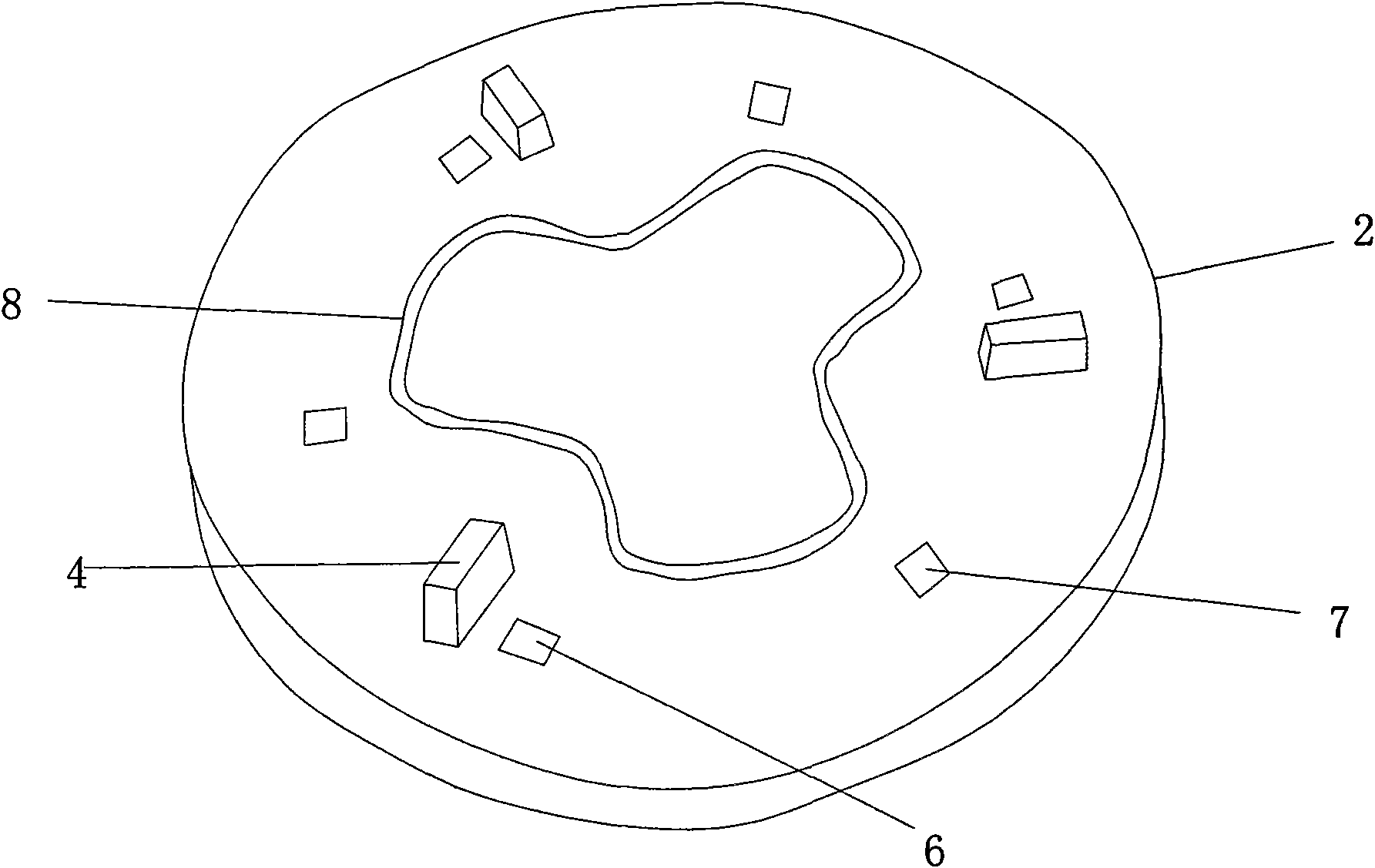

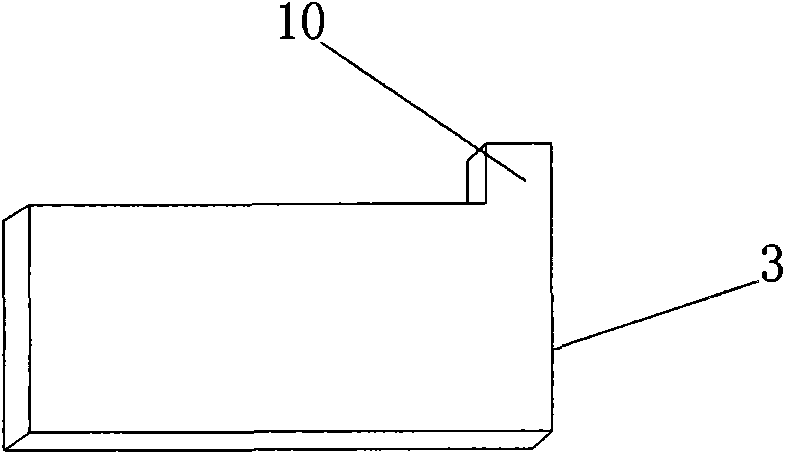

[0035] The controllable wheel groove slow-flow water wheel / water pump machine of the present invention comprises at least one hydraulic drive unit, and the hydraulic drive unit is installed on the output shaft; each hydraulic drive unit consists of a rotating wheel 1, a sealing cover 2 and a plurality of The sealing cover 2 is rotatably assembled in the water flow groove 5 of the rotating wheel 1, and the water flow groove 5 is matched with the water inlet hole 6 on the sealing cover 2. At the same time, the sealing cover 2 is also equipped with multiple The water outlet hole 7 matched with the water flow groove 5, the water inlet hole 6 is connected with the water source; a plurality of radial movable chutes 9 along the circumferential direction are also provided on the rotating wheel 1, and each sealing device is respectively arranged on the correspond...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap