Electric blower and electric duct collector equipped with the same

A technology for electric motors and blowers, applied in vacuum cleaners, machines/engines, liquid fuel engines, etc., can solve the problems of reduced reliability of electric blowers, hindering mainstream deceleration, and enlarging the interior of the blower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

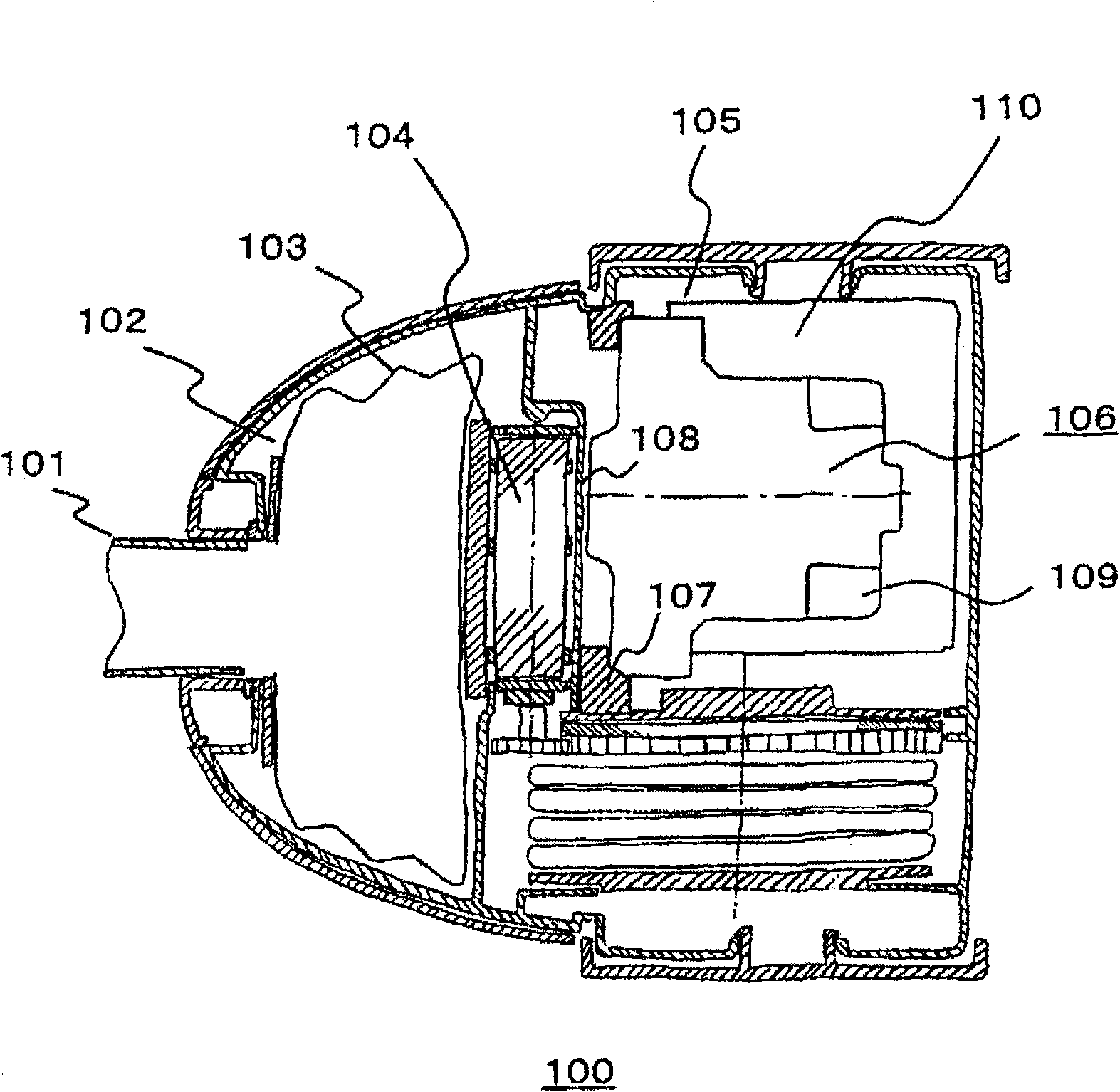

[0029] figure 1 A cross-sectional view of the main body of the vacuum cleaner showing the model. exist figure 1 , the air flow in the cleaner main body 100 will be described. A hose joint 101 is connected to the cleaner main body 100 so as to communicate with the dust collection chamber. The air flowing in from the hose joint 101 enters the dust collecting chamber 102 . exist figure 1 The paper bag 103 is shown as a dust collection unit in , and the raw material of the bag is not limited. Furthermore, in the case of the cyclone system using centrifugal separation, collection is performed in a cyclone chamber instead of the paper bag 103 . The air from which most of the dust has been removed by the paper bag 103 passes through the filter unit 104, where fine dust is also removed. Then, the airflow flows into the motor chamber 105 . The electric blower 106 is suspended in the motor chamber 105 by the anti-vibration rubber 107 , and the air flowing in from the blower inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com