Nondestructive quantitative detecting method and device for internal defects of refractory brick

A technology of internal defects and detection methods, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using radiation for material analysis, etc. It can solve the problems of whether the quality meets the requirements, it is difficult to quantify, the cost of instrument operation and detection is insufficient, and production is inconvenient. Achieve the effect of simple structure, reliable performance and lower detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

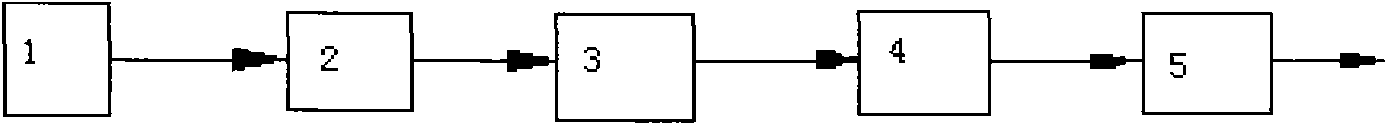

[0017] Such as figure 1 As shown, the refractory brick 1 to be tested is placed at the sensor, and it is stimulated (knocked) with a pulse hammer or a small hand hammer. The intensity of the excitation can make the response sound of the refractory brick after being excited enough to drive subsequent circuits and instruments. The intensity should not be too large, so as not to cause new damage to the refractory brick; at this time, the response sound of the refractory brick is a mechanical quantity, which is converted into electricity (voltage or current) by the sound sensor 2, and the electricity is passed through the conversion circuit. 3 After the conversion, a waveform diagram similar to the output of the sound sensor is obtained. The waveform diagram is a time-domain signal of the refractory brick being knocked. The domain signal is analyzed by the spectrum analysis function block 4 to obtain the self-power spectrogram of the tested piece, that is, the spectrogram of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com