Production process of UV transfer printing molded key device

A production process and key technology, applied in the field of UV transfer printing ultra-thin key production process, can solve problems such as difficulty in raw materials, and achieve the effect of simple operation steps, powerful functions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

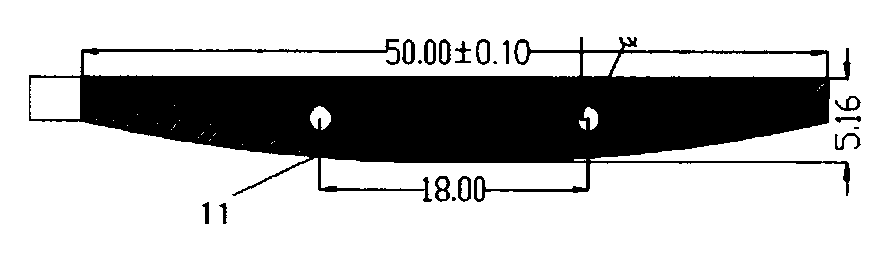

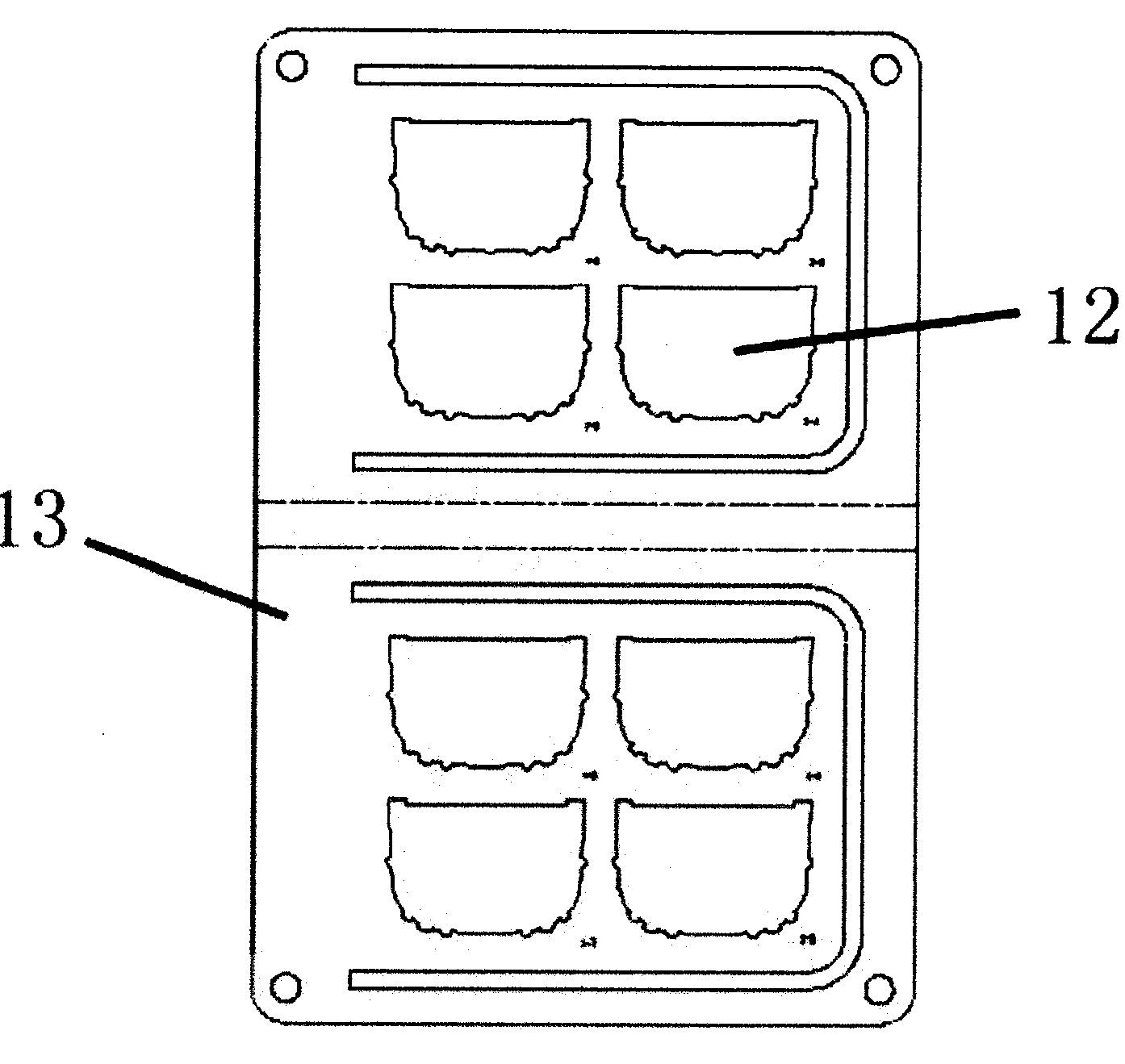

[0031] see figure 2 and Figure 4 The numerical value units marked in are all (mm).

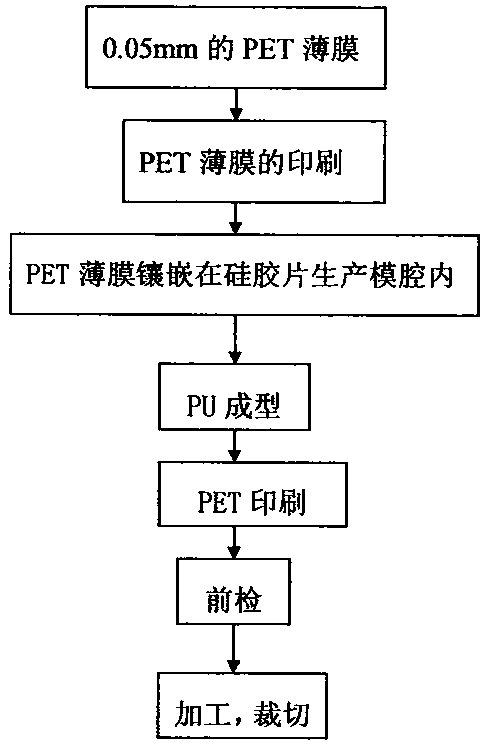

[0032] see figure 1 , the main steps of producing HF-0568 keys by UV transfer printing key production process:

[0033] (1) Pre-drying: unwind the whole roll of PC sheet and pre-dry it with infrared rays. The pre-drying condition is 120°C / 8min;

[0034] (2) Oil pressure: punching edge of PC sheet, punching size is 180×140mm;

[0035] (3) PET film printing: discharge the product, discharge (put the product printing surface), then print varnish and add sulfur (120°C / 0.5H), then print adhesive, add sulfur (120°C / 1H);

[0036] (4) PU molding: dispensing glue on the PU production mold 13, covering with PET film, pressing and rolling, passing through a UV light curing machine (20±5S, temperature is 55±5°C), and demoulding;

[0037] (5) Printing: The operation process is to discharge the product → discharge (put the product printing surface) → hollow character → add sulfur (60°C / 0.5H) → black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com