Method for manufacturing integrated circuit

A manufacturing method and technology of integrated circuits, which are applied in the direction of circuits, electrical components, electrical solid devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The aforementioned and other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of two preferred embodiments shown with reference to the accompanying drawings.

[0033] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

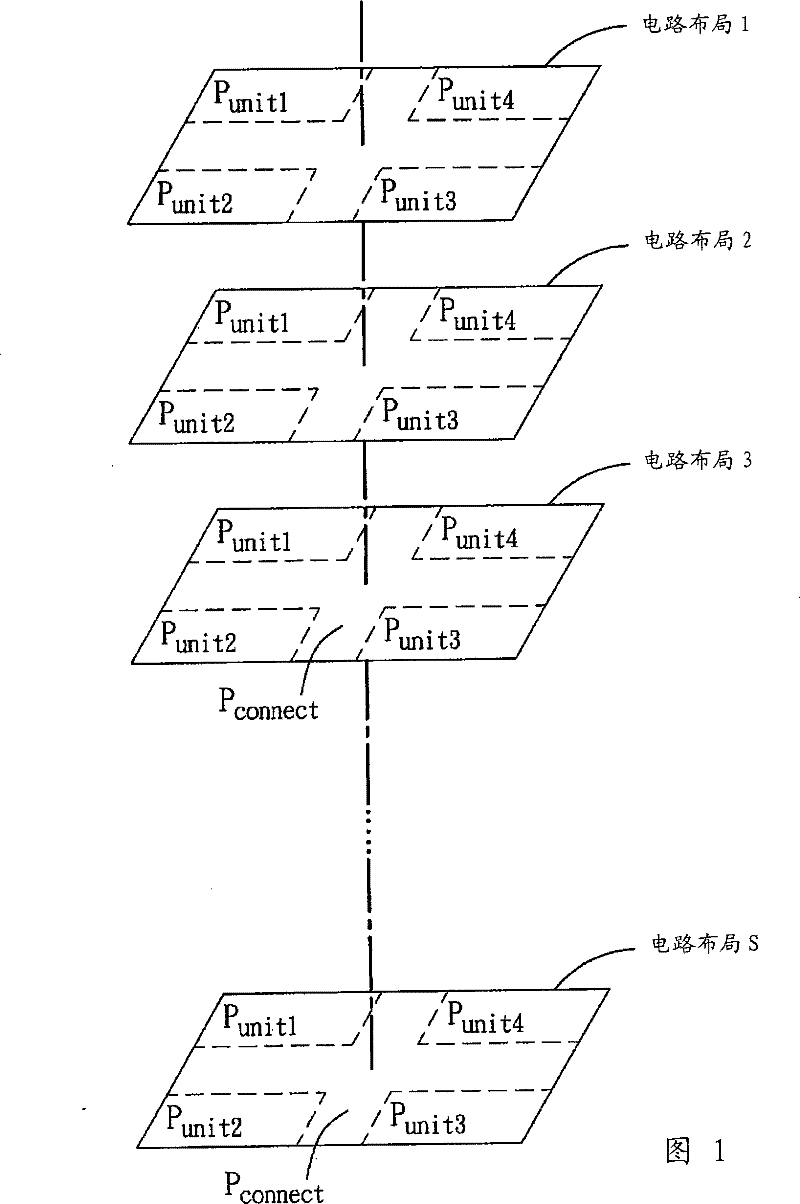

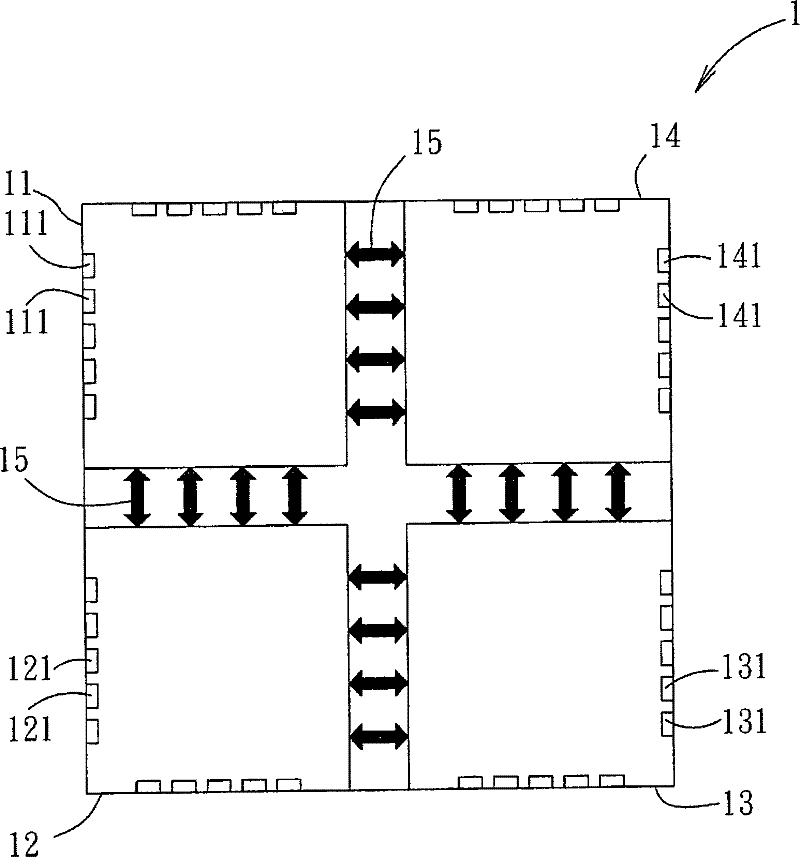

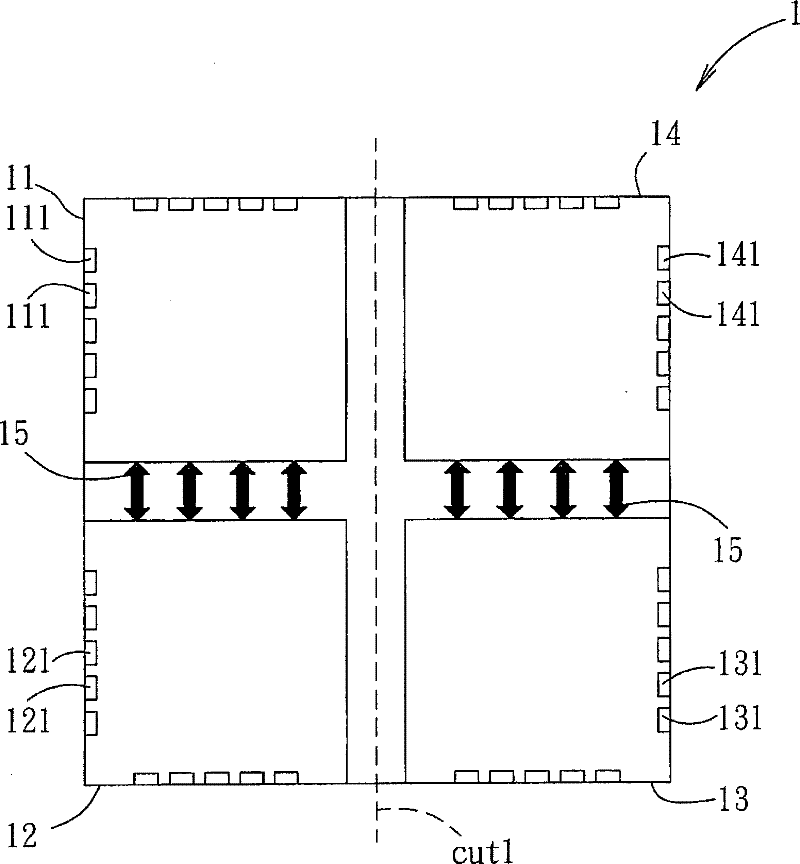

[0034] The preferred embodiment of the integrated circuit manufacturing method of the present invention is suitable for producing a variety of chips including different numbers of hardware units, and each hardware unit can operate independently or combined, for example: each hardware unit can be used as a receiver of a wireless communication system. The main principle is to integrate and route multiple hardware units with similar functions in the S-layer circuit layout (layout), and then after photomask fabrication and chip processing, it is cut and packaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com