Fireproof method of cloth dust collector

A bag dust collector and drying technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as cloth bag fire, achieve the effect of protecting cloth bags, simple process method, and preventing dust spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

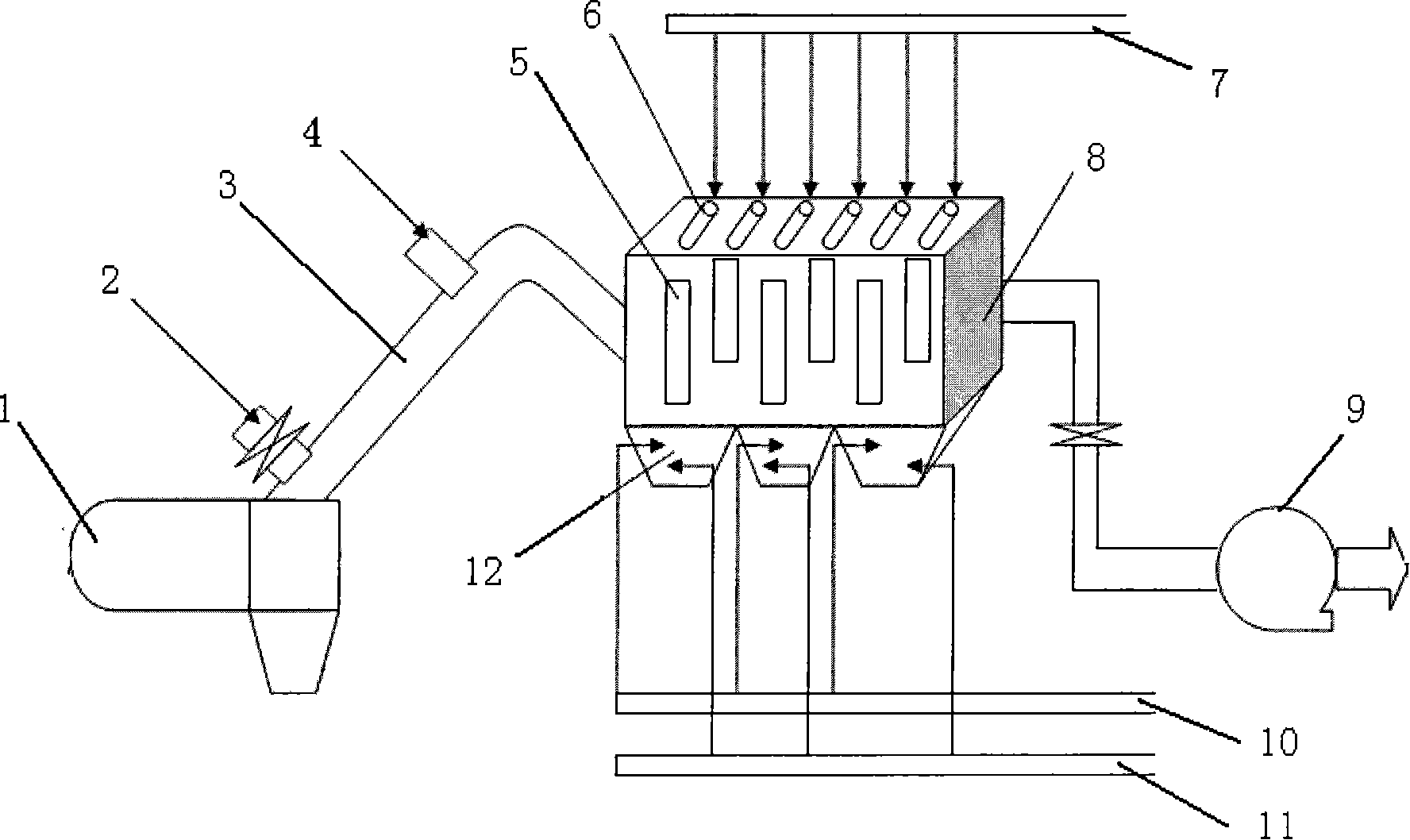

[0012] Such as figure 1 As shown, the dust-containing gas from the steam drying kiln 1 is transported to the bag filter 8 by the conveying pipeline 3, the tail gas is discharged by the fan 9, the dust is discharged from the ash hopper 12 below the bag filter, and the dust is distributed above the bag filter There is an anti-blow pipe 6. The flame retardant gas is sent into the anti-blow pipe 6 through the pipe 7 and blown into the bag 5, and at the same time, the flame retardant gas is added to the delivery pipe 3 leading to the inlet of the bag filter 8, so that the oxygen content in the bag filter is diluted to 16 %the following. Nitrogen is used as the blowback gas, and the flame retardant gas added to the delivery pipeline 3 is nitrogen and / or saturated water vapor, and the nitrogen used can be industrial waste nitrogen. Nitrogen and steam are fed through inlets 2 and 4 respectively, and can also be directly fed into drying kiln 1.

[0013] Since the air at the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com