Adjustable eccentric transmission device for machine tool, in particular for superfinishing or honing

An eccentric transmission and guiding device technology, which is applied in the direction of superfinishing machines, honing machines, grinding drives, etc., can solve the problems of time-consuming adjustment or change, inability to affect and optimize surface quality, high cost, etc., and achieve high efficiency The effect of structural form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

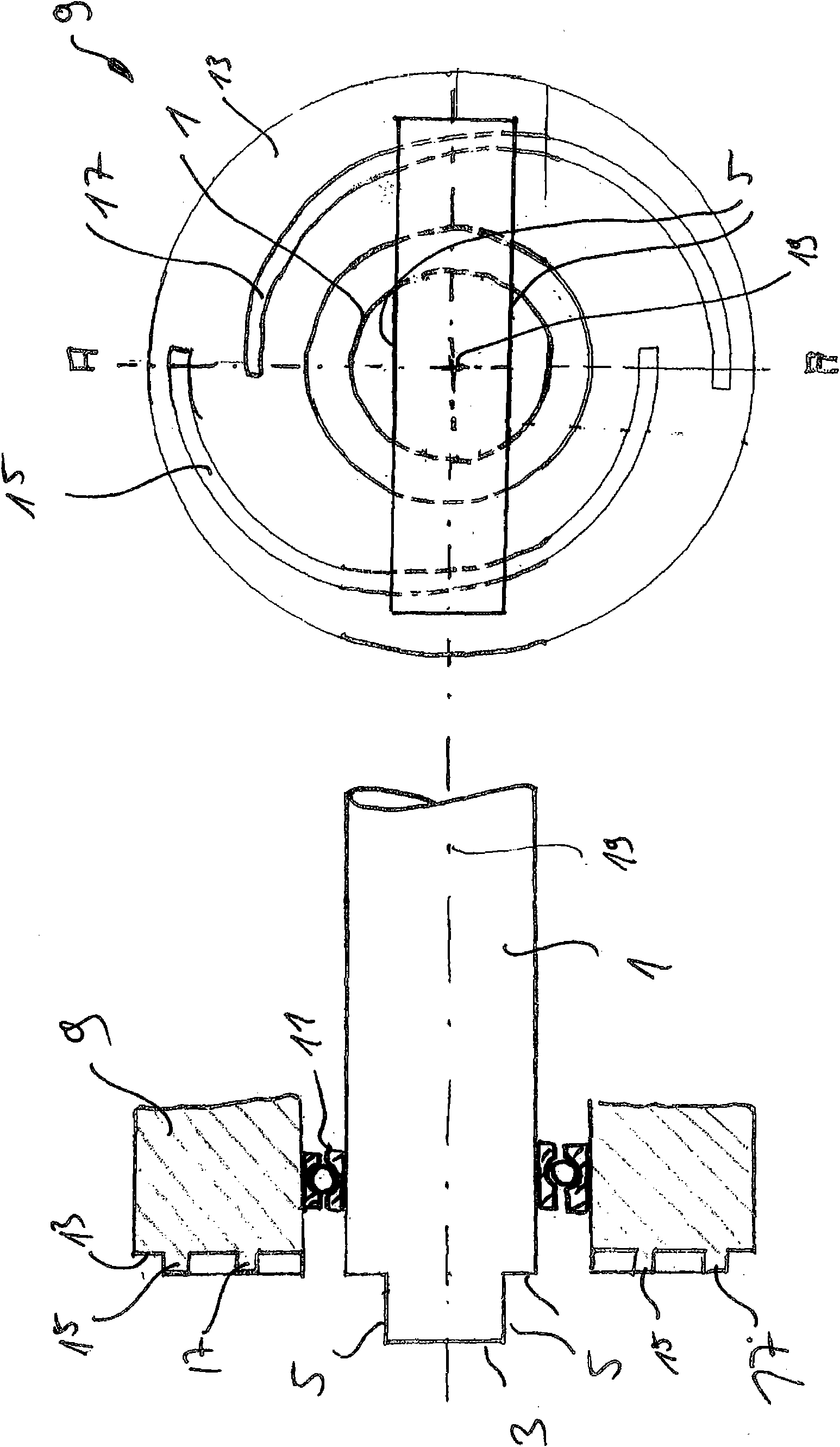

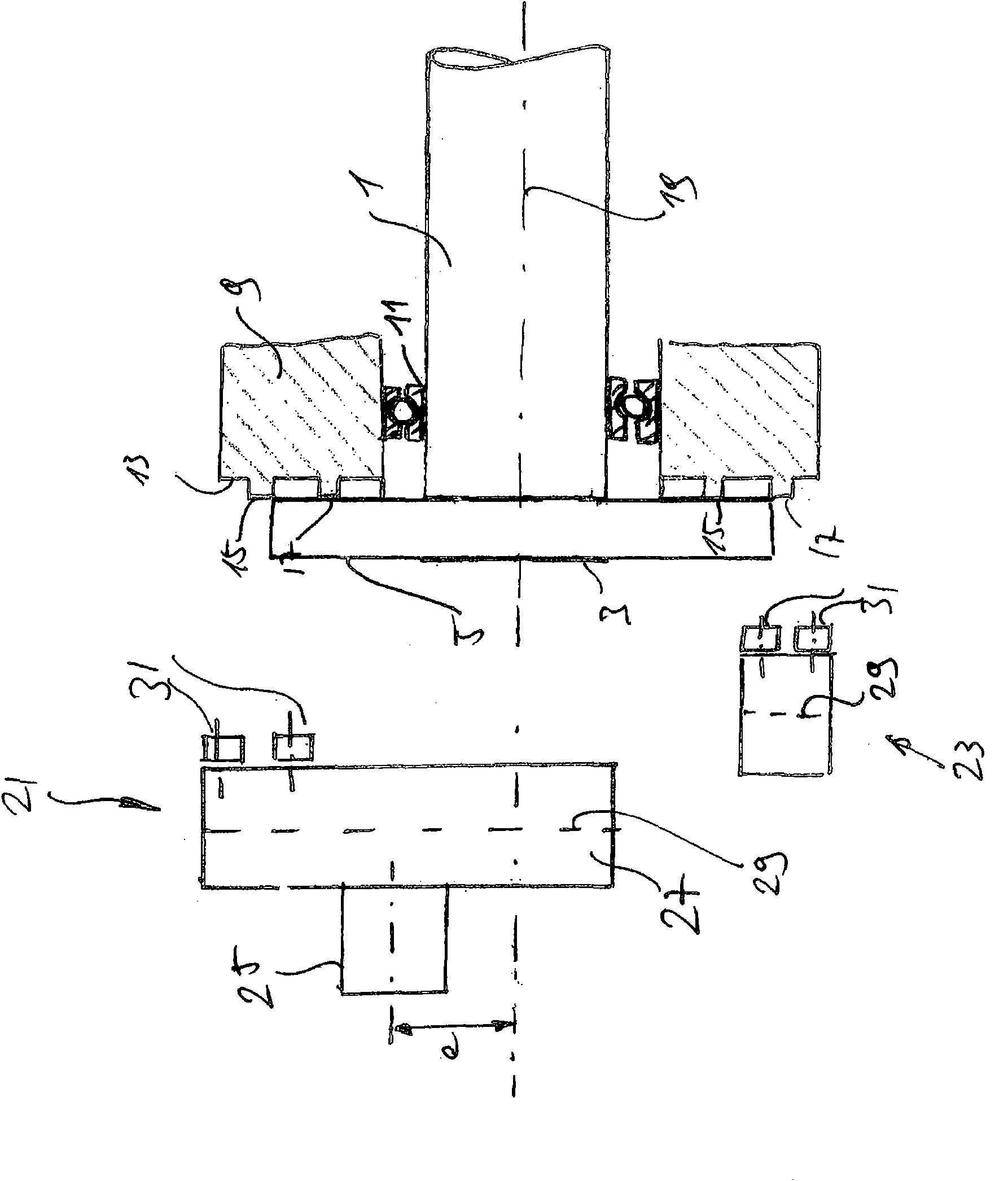

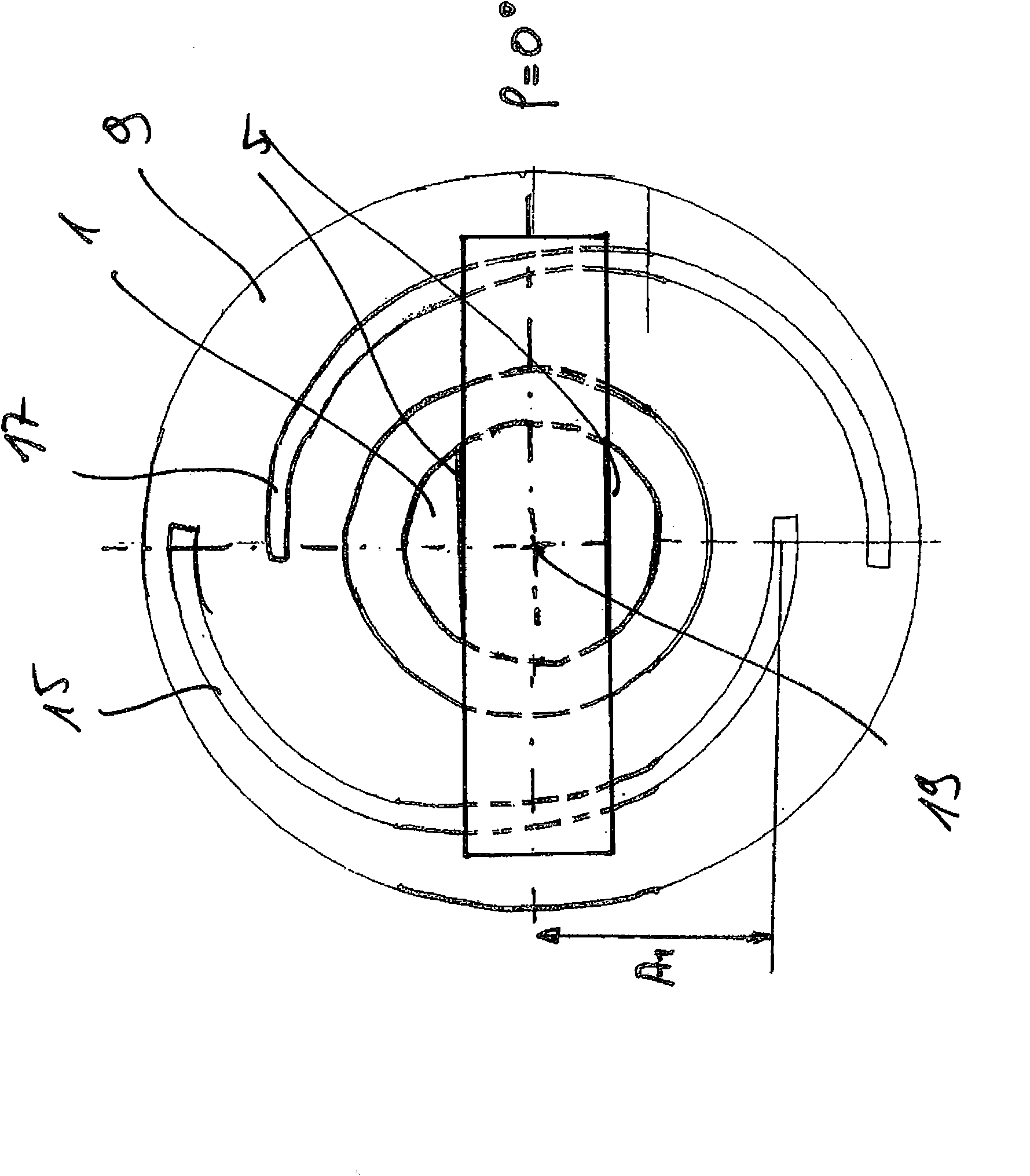

[0029] The figure shows a first axis 1 . The first shaft 1 is mounted rotatably in a housing, not shown. A linear guide 5 is formed on one end face 3 of the first shaft. A bearing 11 is arranged between the adjusting ring 9 and the first shaft 1 . This means that the setting ring 9 is rotatable relative to the first shaft 1 . One end face 13 of the setting ring 3 has a first guide rib 15 and a second guide rib 17 . The guide ribs 15 and 17 are helical within the scope of the invention, since the distance of the guide ribs from the axis of rotation 19 of the first shaft 1 is angle-dependent. exist figure 1 In the exemplary embodiment shown, the helical ribs 15 and 17 are designed as arc segments which are arranged eccentrically with respect to the axis of rotation 19 . However, it is also possible to design the helical ribs 15 and 17 as Archimedean or logarithmic spirals. It is also possible to design the lift of the helix to be related to the angle.

[0030] When the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com