Method for cutting glass by laser

A laser cutting and glass technology, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of low efficiency and achieve the effect of fast and high-quality cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

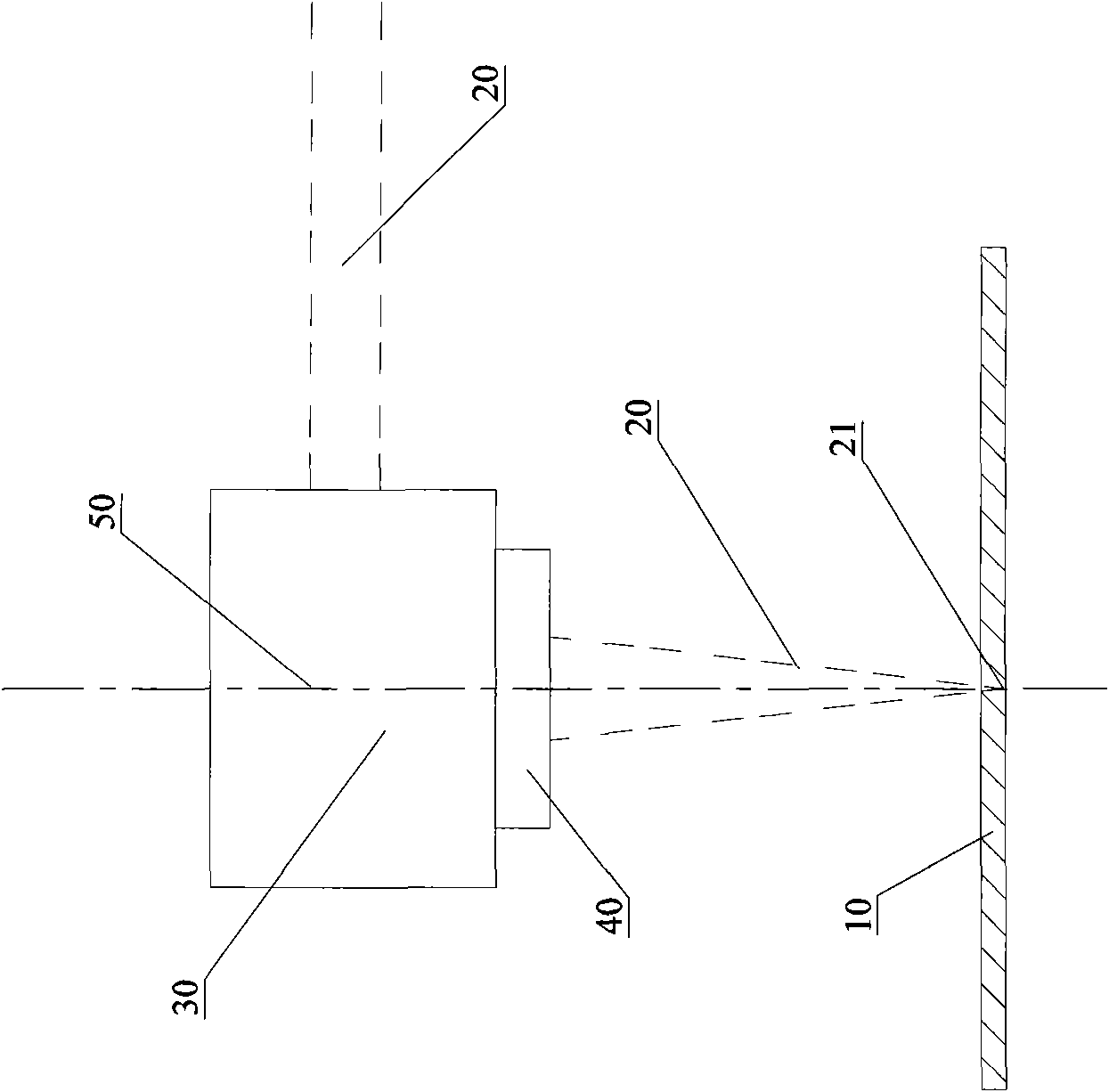

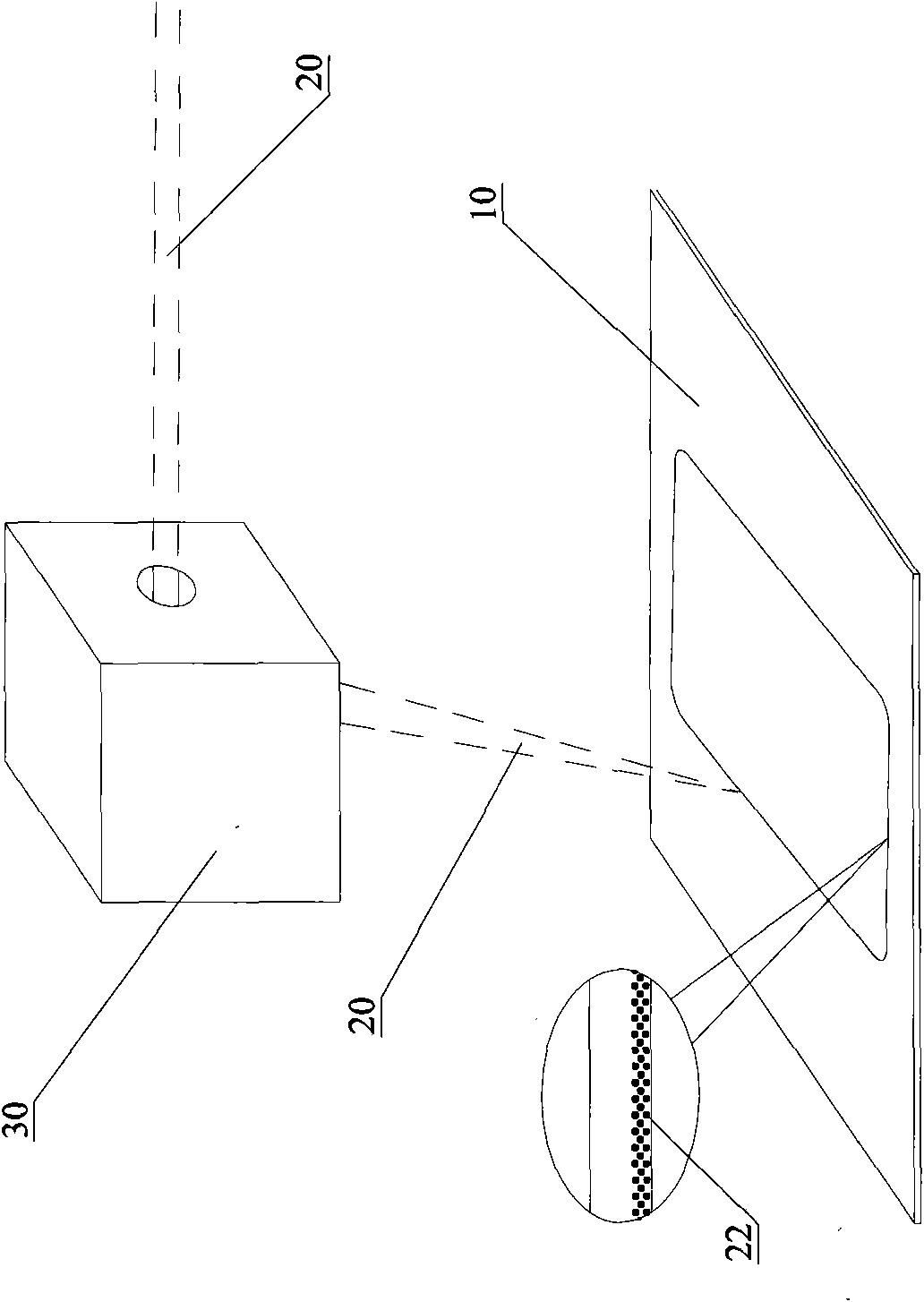

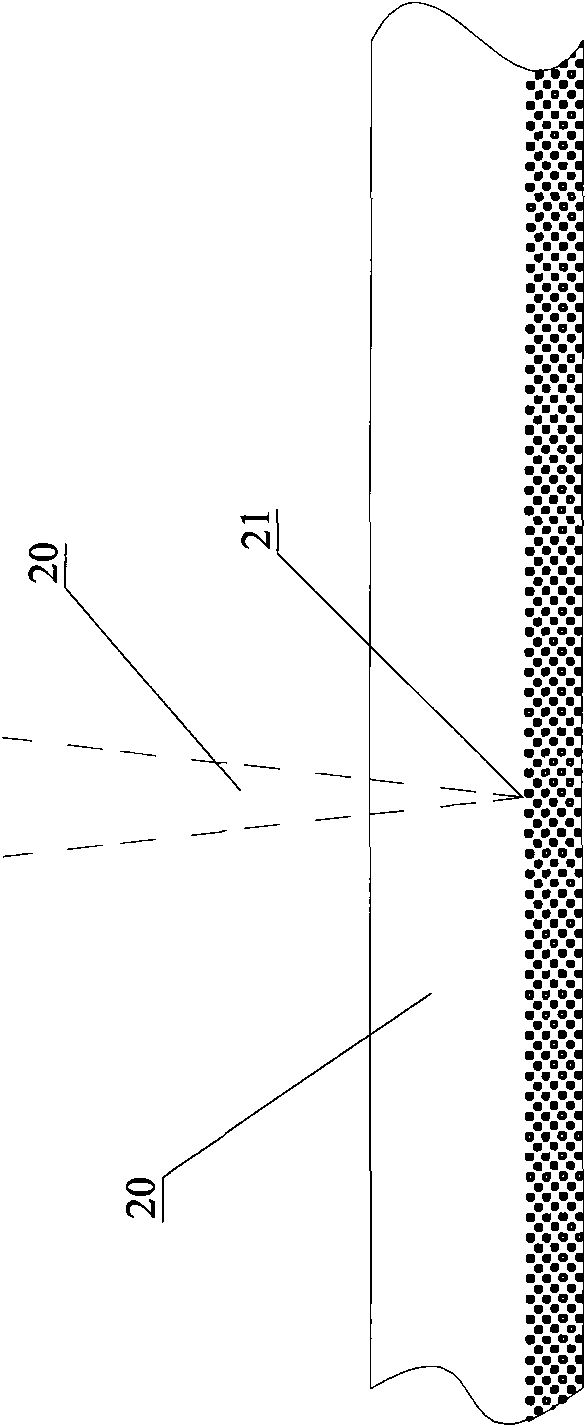

[0017] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0018] The method for laser cutting glass of the present invention adopts a Q-switched pulsed ultraviolet laser with a wavelength of 355nm or a Q-switched pulsed green laser with a wavelength of 532nm, and the processing material has a low absorption rate for the ultraviolet laser or the green laser and is easy to penetrate glass, or Transparent, fragile, hard materials like glass, and this method is suitable for cutting straight lines and large radius curves. However, the energy density of the laser near the focal point is extremely high, and it is easy to exceed the damage threshold of the material so that the material absorbs enough energy to cause the material to produce tiny burst points. The laser chooses a laser with high pulse single-point energy and narrow pulse width, so that it can have a larger peak power and it is easier to exceed the process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com