Bottom-blown air brick of top and bottom repeatedly blown converter and installing structure thereof

A converter bottom blowing, top and bottom combined blowing technology, applied in the manufacture of converters, etc., can solve the problem of blockage and short melting of bottom blowing air bricks, so as to ensure air permeability, improve service life, and solve the problems of blockage or short melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

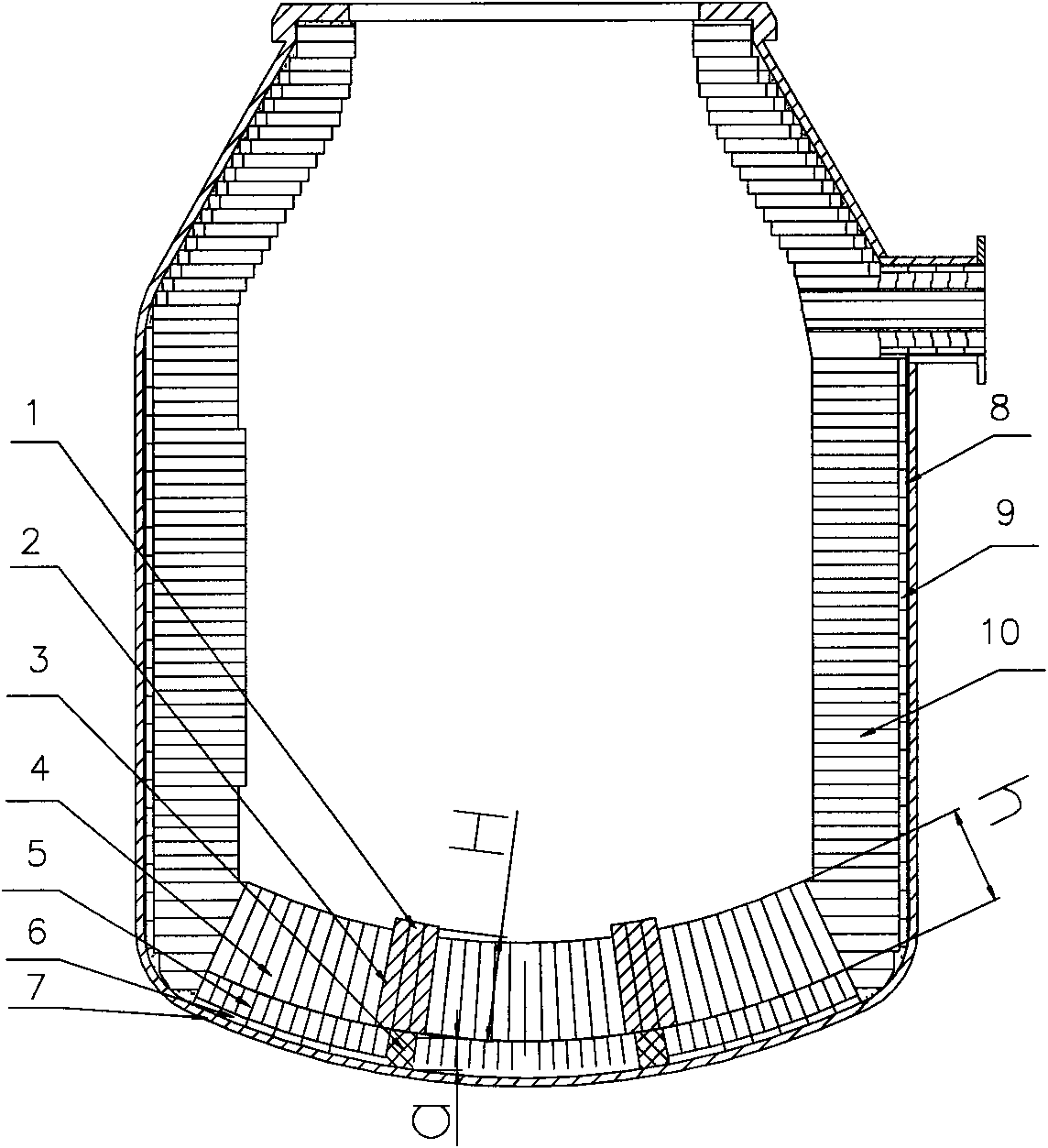

[0020] Such as figure 1 As shown, a top-bottom re-blowing converter bottom-blown air-permeable brick is composed of an air-permeable brick 1, an air-permeable brick seat brick 3 and two protective bricks 2, the protective brick 2 is located on both sides of the air-permeable brick 1, and the air-permeable brick seat brick 3 is located The lower part of the breathable brick 1, and the center hole is aligned up and down.

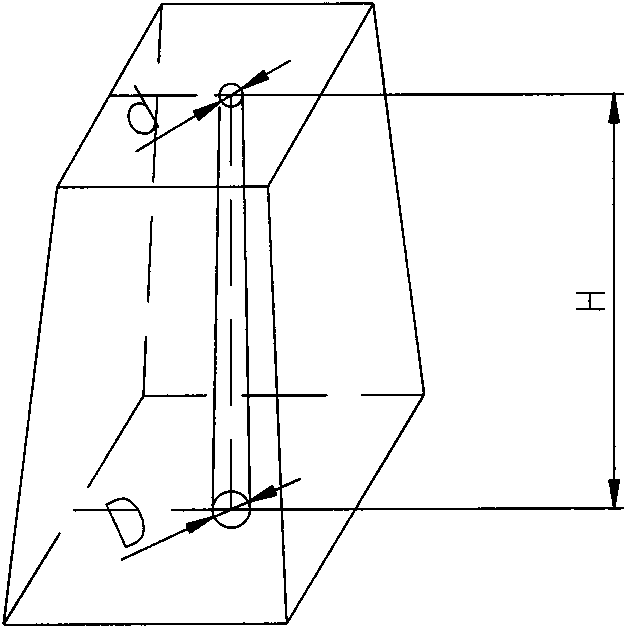

[0021] Such as figure 2 As shown, the materials of the breathable brick 1 and the protective brick 2 are both magnesia carbon, the grade is MT-18AA, the physical and chemical indicators are: MgO: 74.86%, C: 18.89%, bulk density: 2.96g / cm3, significantly Porosity: 2.98%, compressive strength at room temperature: 39.83Mpa, flexural strength (1400°C×0.5h): 12.4Mpa; breathable brick 1 and protective brick 2 have the same dimensions, both of which are wedge-shaped with trapezoidal surfaces. The lower two faces are rectangular, and the front, back, left, and righ...

Embodiment 2

[0025] Others are the same as in Example 1, except that the lower aperture D of the permeable brick 1 is 26 mm, and the upper aperture d is 24 mm.

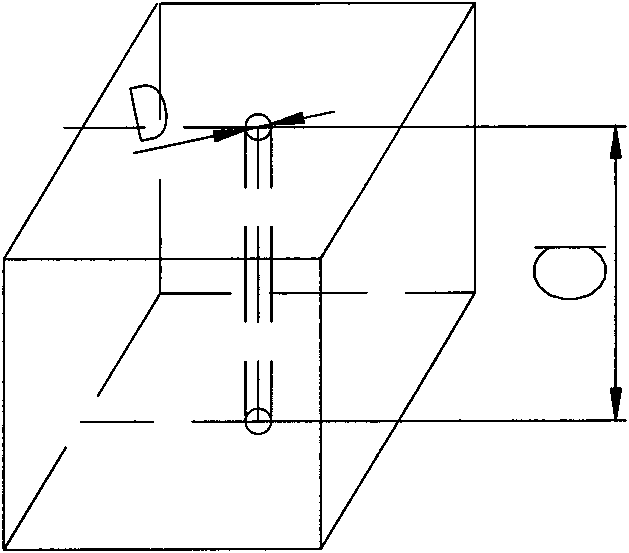

[0026] The central aperture D of the air-permeable brick seat brick 3 is 26mm. Bottom blowing ventilation brick 1 and both side protection bricks 2 are 110mm higher than furnace bottom working lining magnesia carbon brick 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com