Novel wind power station

A power station, a new type of technology, applied in wind power generation, wind power motor combination, wind power generator components, etc., can solve the problems of high cost, difficult wind wheel, difficult transportation and installation, etc., and achieve reduced maintenance cost, ingenious assembly and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

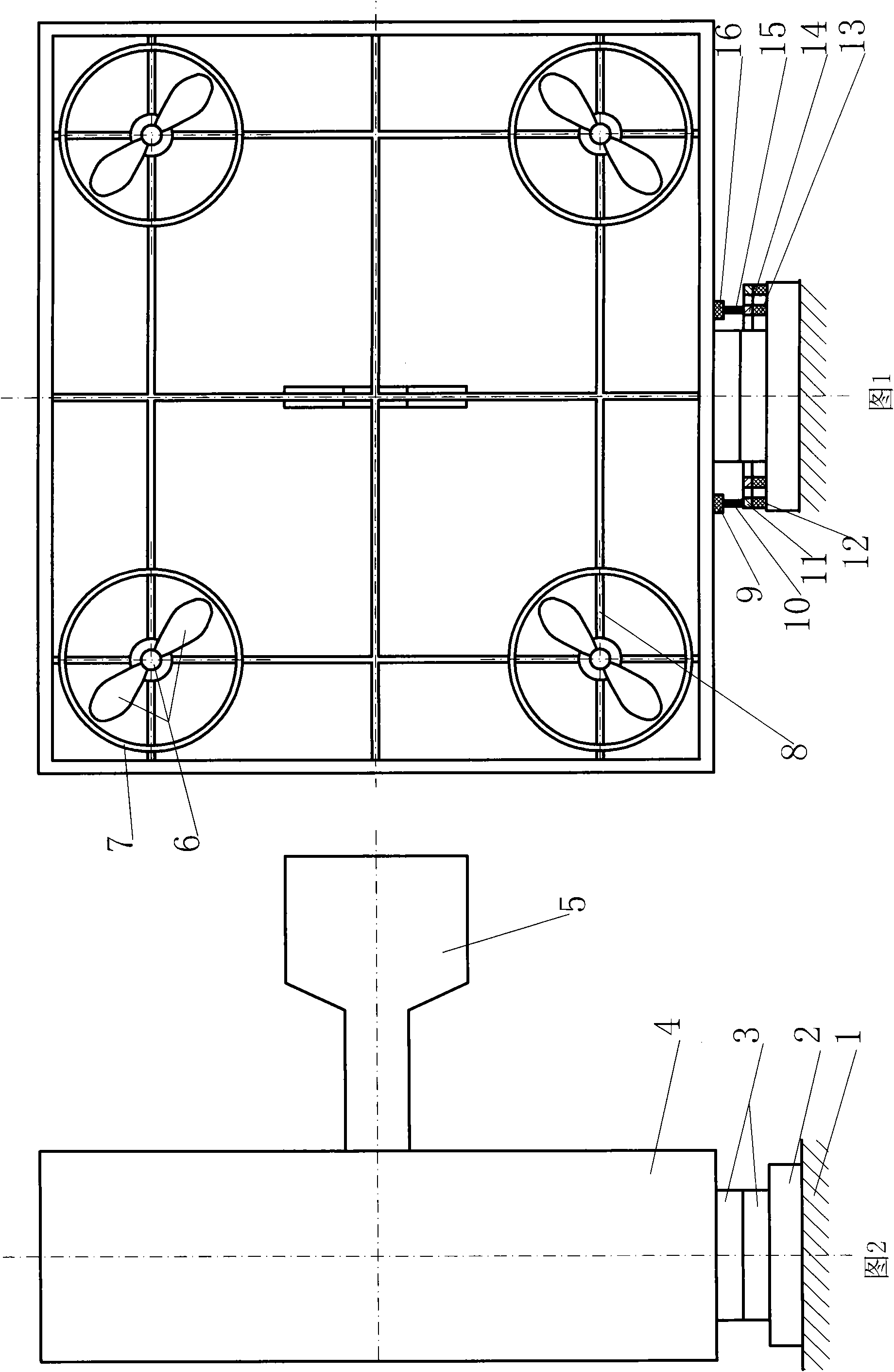

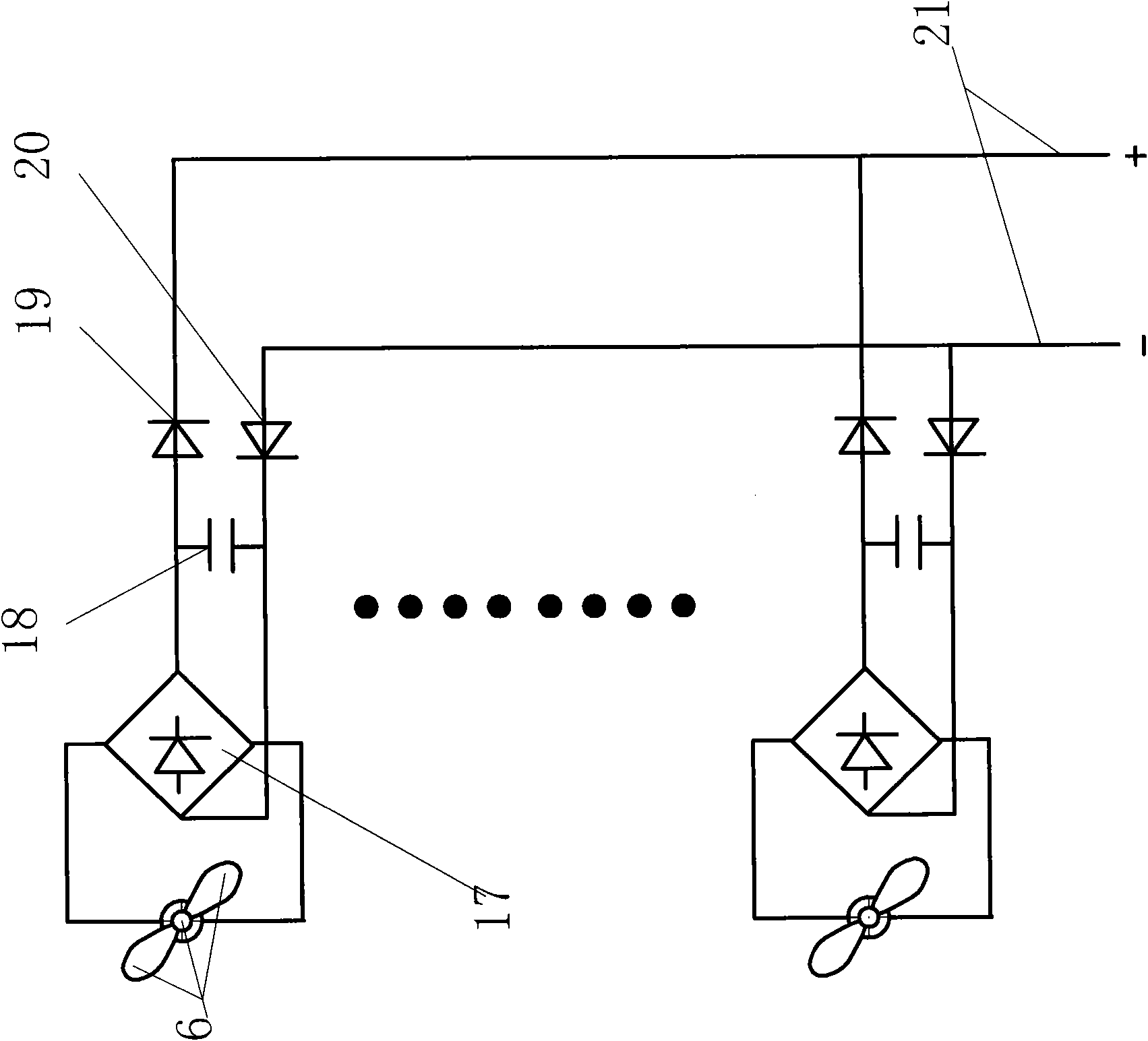

[0021] Embodiment one: if figure 1 figure 2 As shown, several small wind generators 6 are arranged and installed in a rectangular or circular frame 4. The wind generators 6 are composed of wind impellers and generators. The wind generators 6 are supported in the ring 7 by connecting rods 8, and each ring The outer circle of 7 is connected, and the outer circle of each annulus 7 near the inner wall of rectangle or circular frame 4 directly or connects with the inner wall of rectangular or circular frame 4 with connecting rod 8; A wind vane 5 is installed in the center of a vertical section, the bottom of the rectangular or circular frame 4 is connected to the base 2 with a thrust bearing 3, and the bottom of the rectangular or circular frame 4 is also fixed with insulating blocks 9 and 16, which are respectively connected on the insulating blocks 9 and 16 Carbon brush assemblies 10 and 15, the base 2 is set on the foundation 1; insulating rings 12 and 13 are arranged on the f...

Embodiment 2

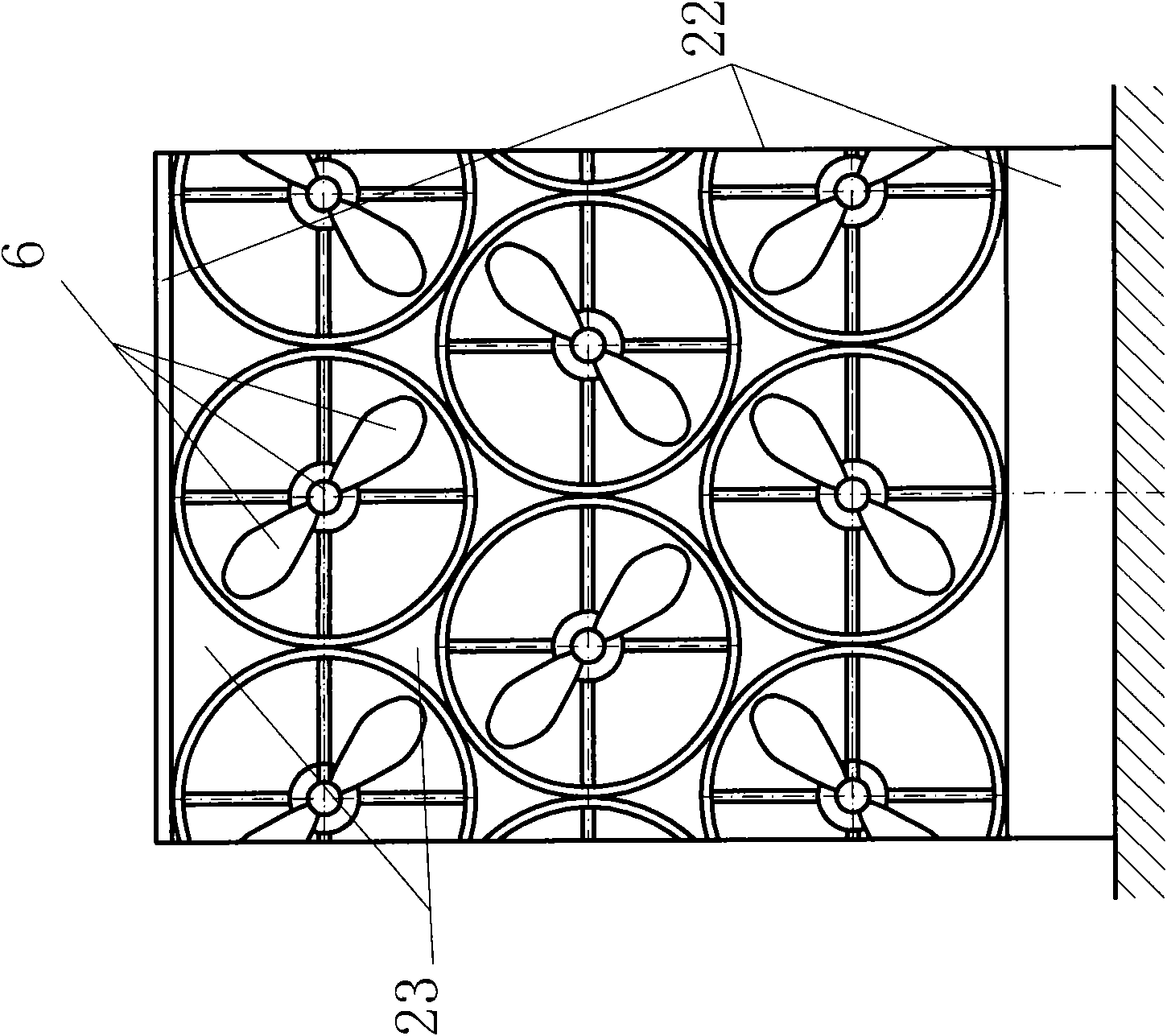

[0022] Embodiment two: if Figure 4 Figure 5 Show. Several small wind-driven generators 6 are arranged and installed in the vertical cylindrical frame 22, and the wind-driven generators 6 are supported in the rings 7 with connecting rods 8, and the outer circles of the rings 7 are connected to each other. The excircle of each annulus 7 of upper top or lower end directly or links with cylindrical frame 22 with connecting rod 8; The bottom of cylindrical frame 22 is fixed on the foundation. The power transmission method is basically the same as Scheme 1, but the generated electricity is directly output from the terminal of the bus 21, which is different from Scheme 1 only in this point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com