Asphalt mixed material road face abrasion simulator and test method thereof

A technology of asphalt mixture and test method, which is applied in the direction of testing wear resistance, etc., to achieve the effect of simple structure, convenient use and flexible testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

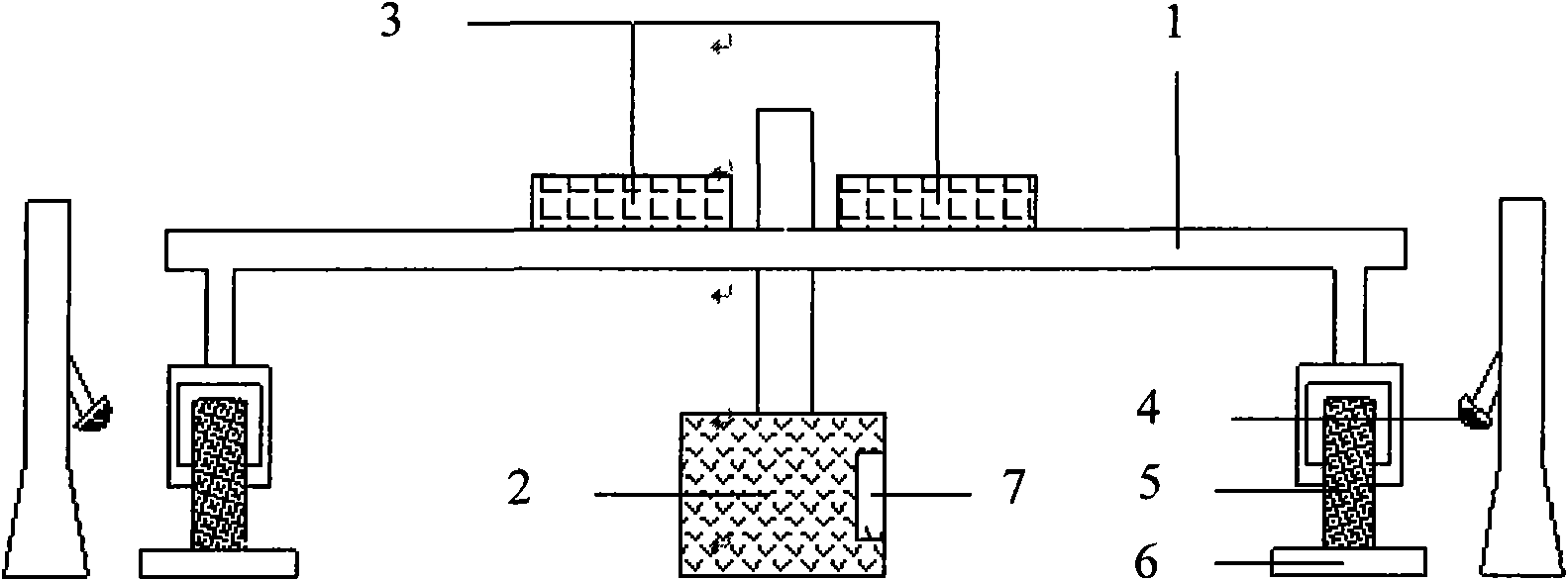

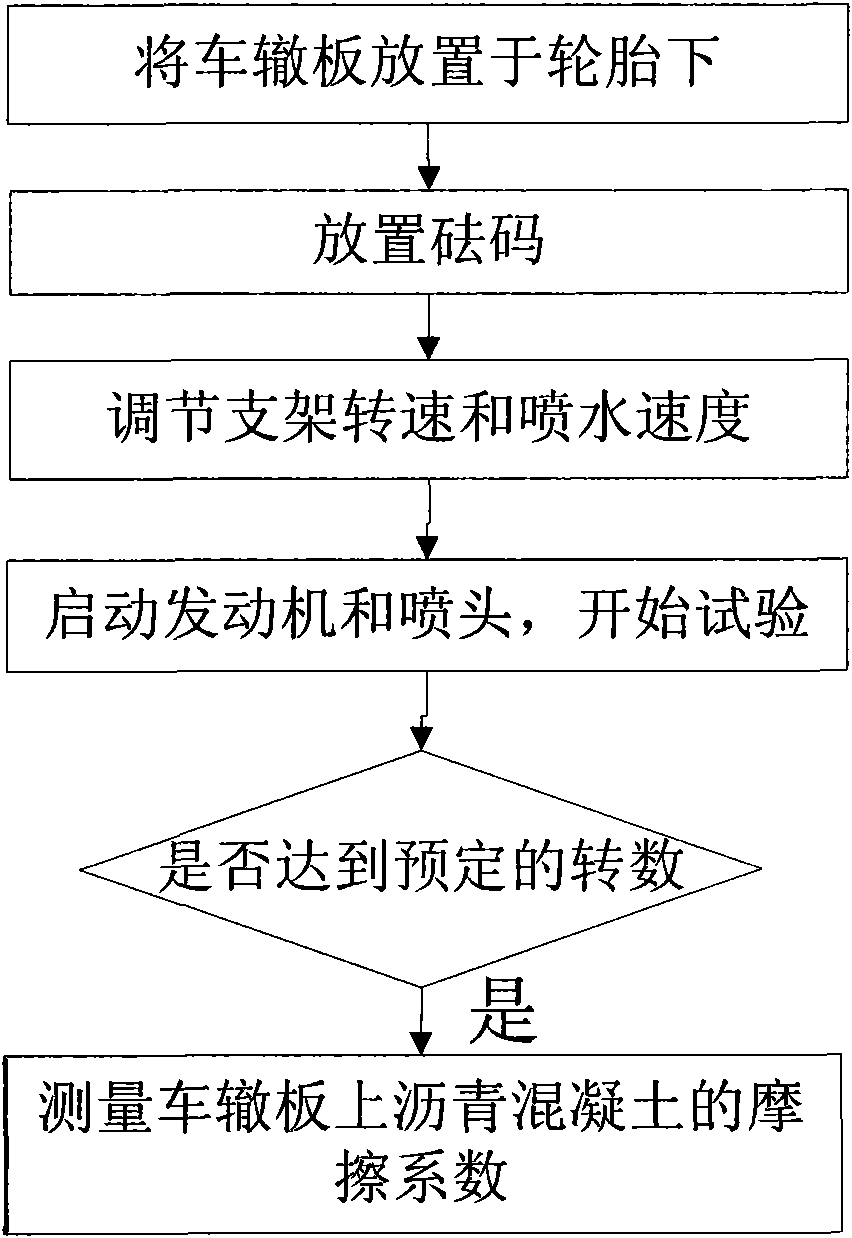

[0030] The asphalt mixture pavement wear simulator of the present invention is jointly formed by support 1, motor 2, weight 3, nozzle 4, tire 5, controller 7, as figure 1 As shown, its specific structure and assembly relationship are as follows:

[0031] The bracket 1 is an I-shaped steel beam that can bear 300KN tension and pressure. At both ends of the bracket 1, tires 5 are assembled on the bracket 1 according to the existing method of assembling tires for electric vehicles, and the motor 2 is assembled under the bracket 1. , the bracket 1 is controlled by the motor 2 and can rotate on a plane at a certain speed. When the bracket 1 is connected with the motor 2, it only bears force in the horizontal direction and can slide freely in the vertical direction. The support 1 is also provided with a device capable of placing a weight 3 . The we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com