Soft-off circuit and method

A soft shutdown and circuit technology, applied in circuits, electronic switches, electrical components, etc., can solve problems such as large stress on the switch tube, and achieve the effects of solving output rebound, realizing shutdown pre-bias, and solving output energy recharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

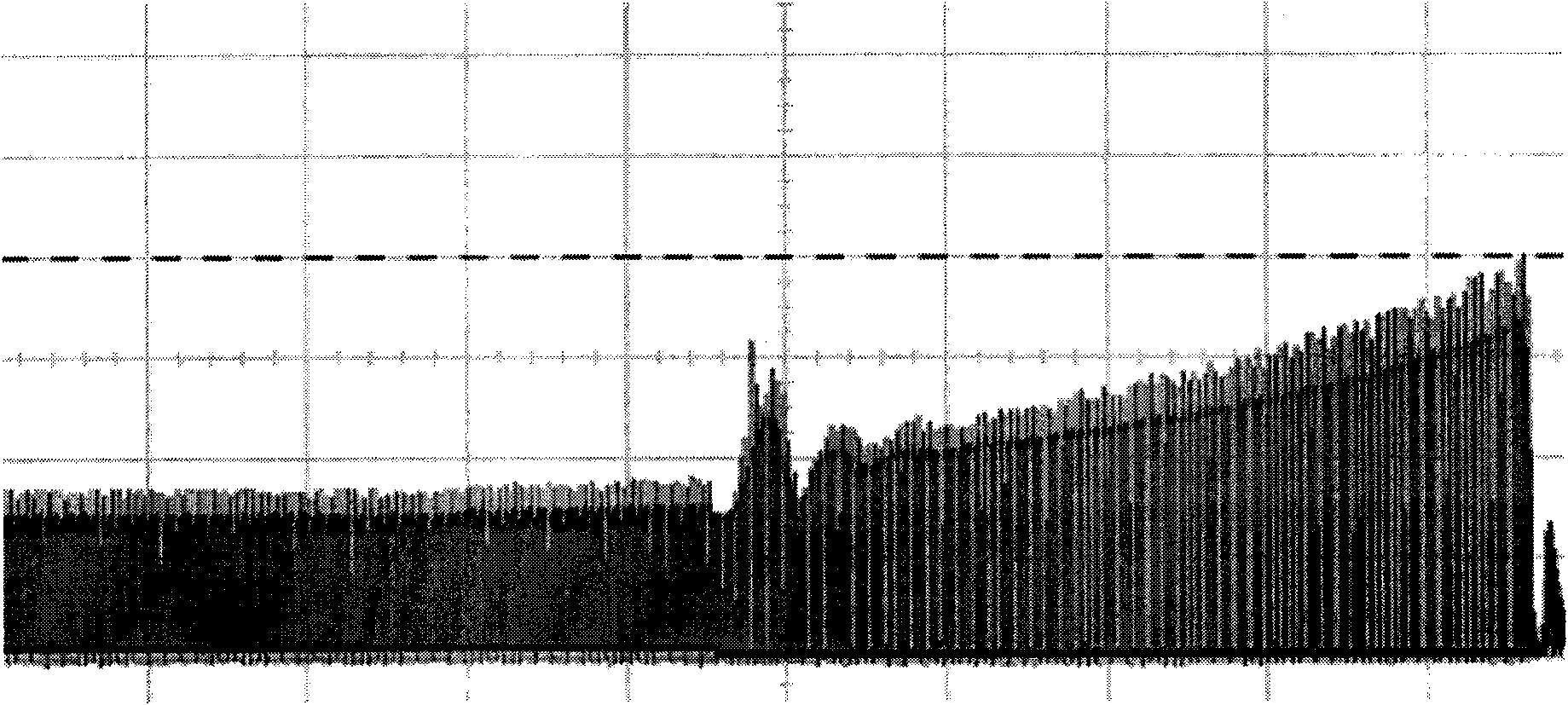

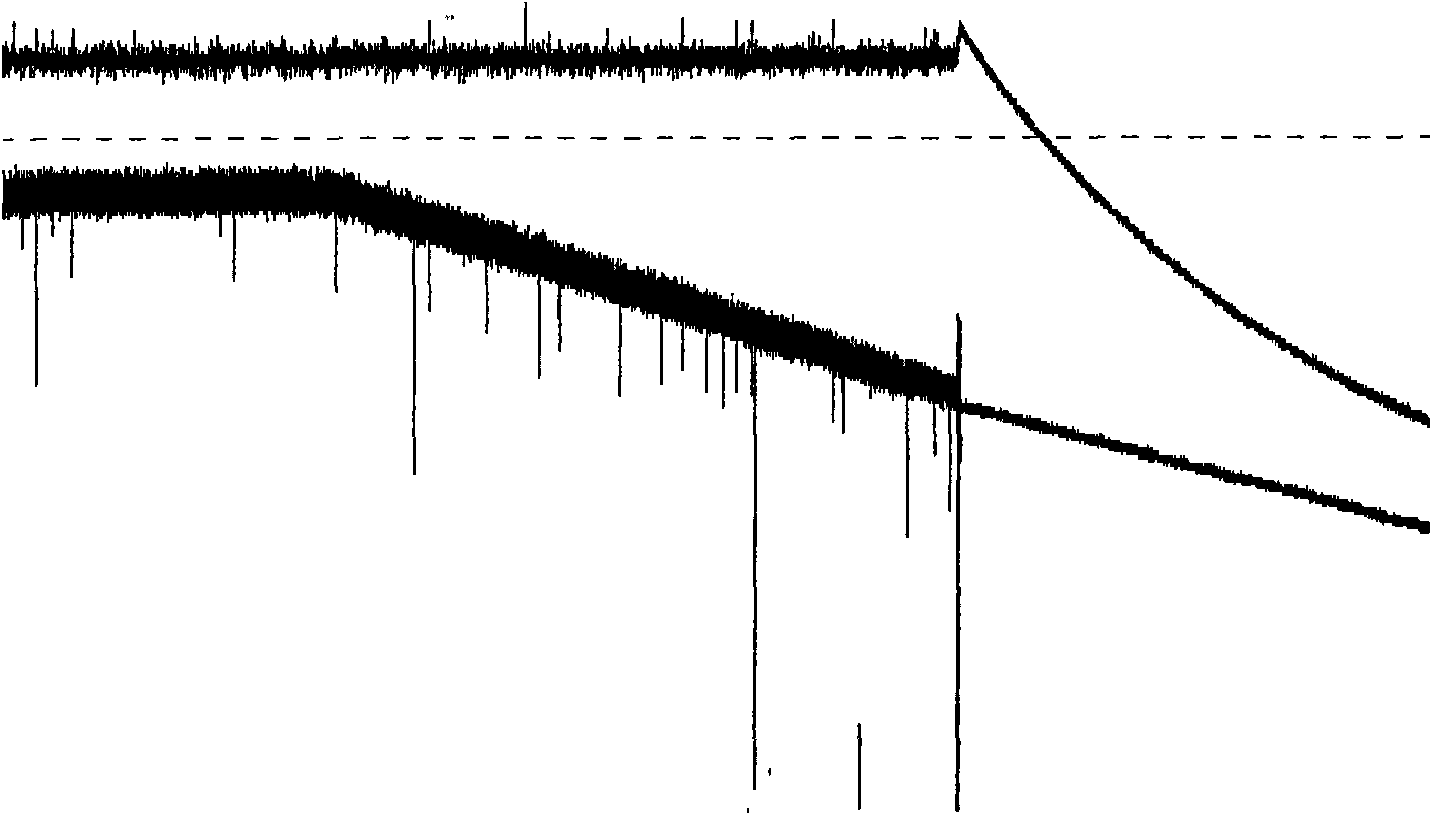

[0041] The basic idea of the present invention is to first limit the duty cycle or frequency, and then shut down after a period of time on the basis of a small duty cycle or frequency, thereby avoiding the stress increase of the switch tube caused by the soft shutdown of the prior art, which is easy damaged defect

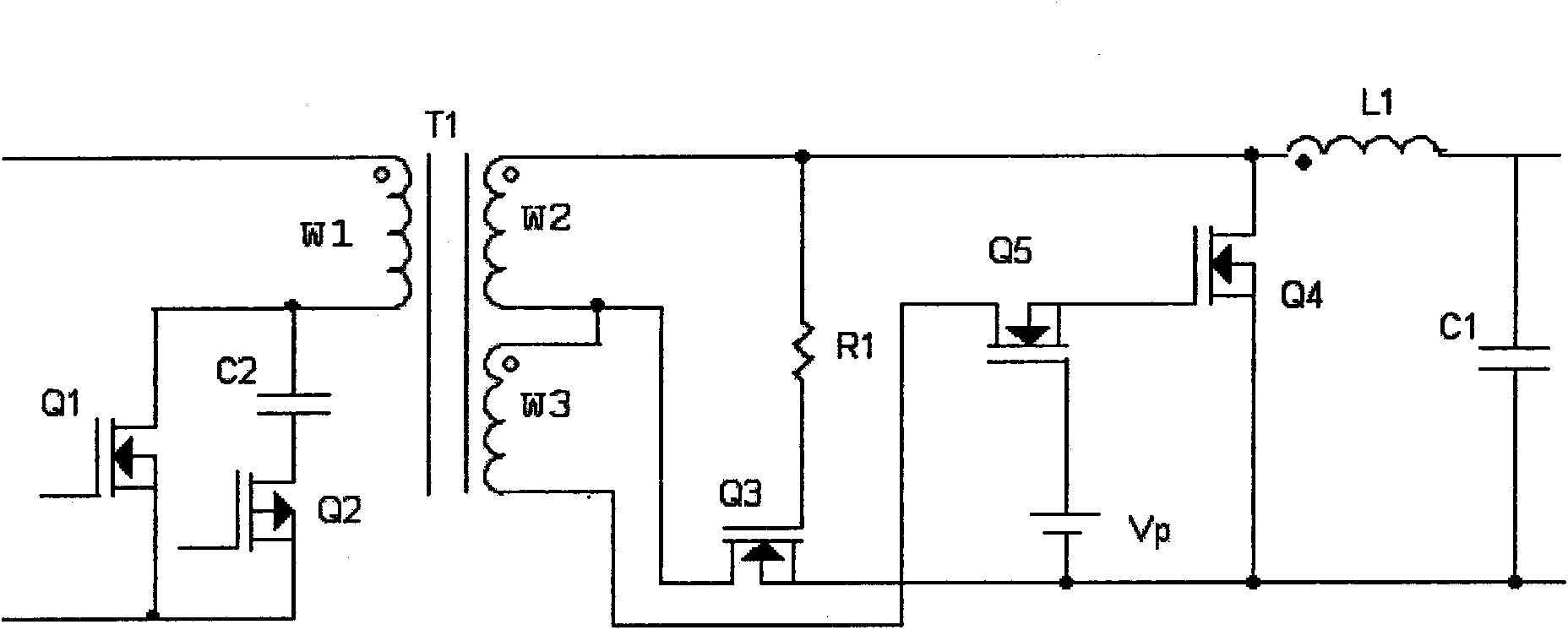

[0042] Figure 4 It is the circuit schematic diagram of the first embodiment of the soft shutdown circuit of the present invention. Such as Figure 4 As shown, the input end of the soft shutdown circuit of the present invention is connected to the external control signal, and the output end is connected to the input end of the frequency / duty ratio adjustment unit ( Figure 4 in the dotted box). The soft shutdown circuit includes: a triode Q1, whose base is connected to the input terminal of the soft shutdown circuit, whose emitter is grounded, and whose collector is connected to the input terminal of the frequency / duty ratio modulation unit via a resistor R2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com