Commercial LED illumination driver

A LED lighting and driver technology, applied in the field of driving circuits, can solve the problem of mining the quality of the power grid of LED driving circuits without considering the overall efficiency improvement and service life of LED light source driving circuits, and propose a complete solution without LED lighting driver design. The service life has not reached the expected value, etc., to achieve the effects of variable scene effects, improved energy efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

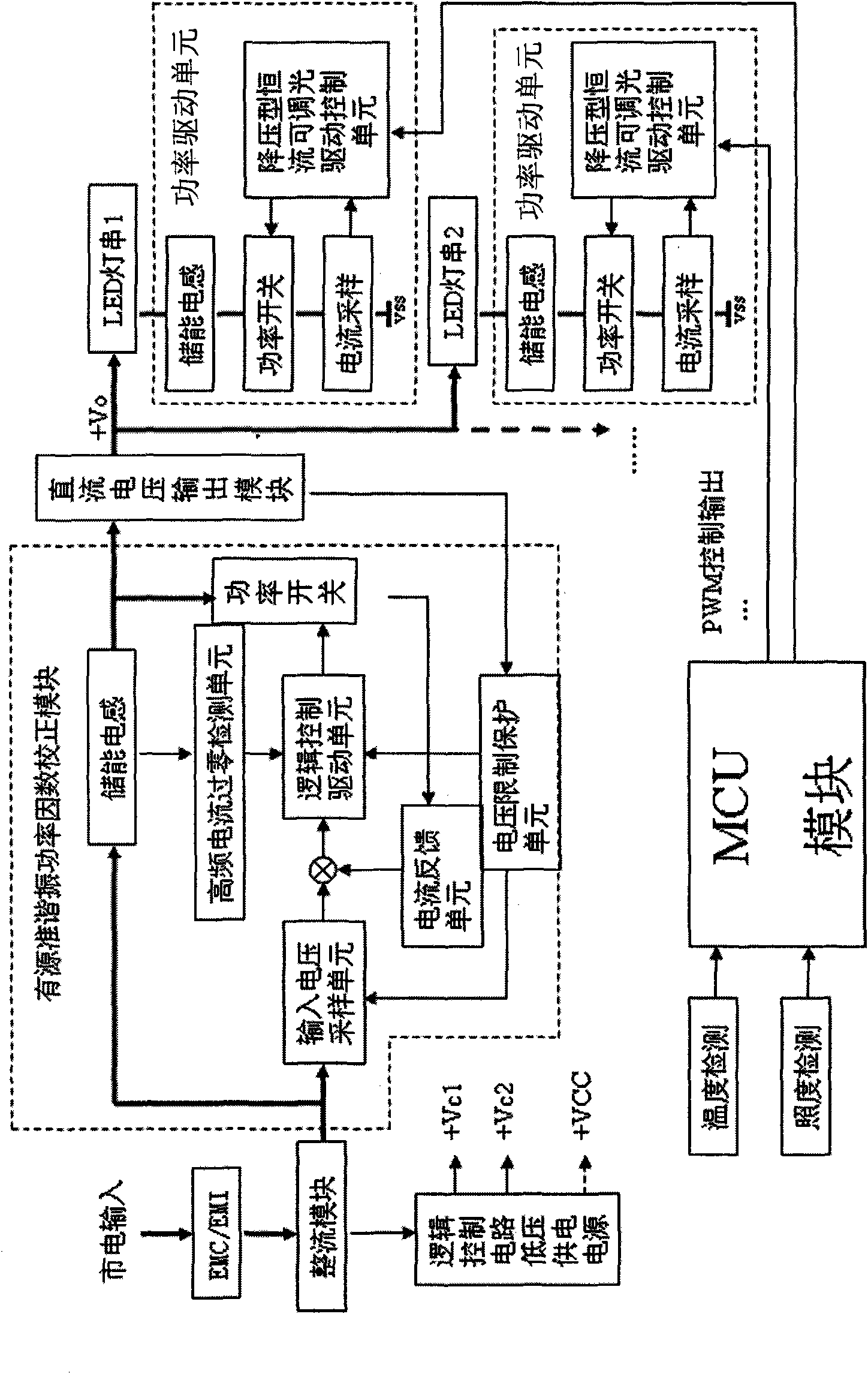

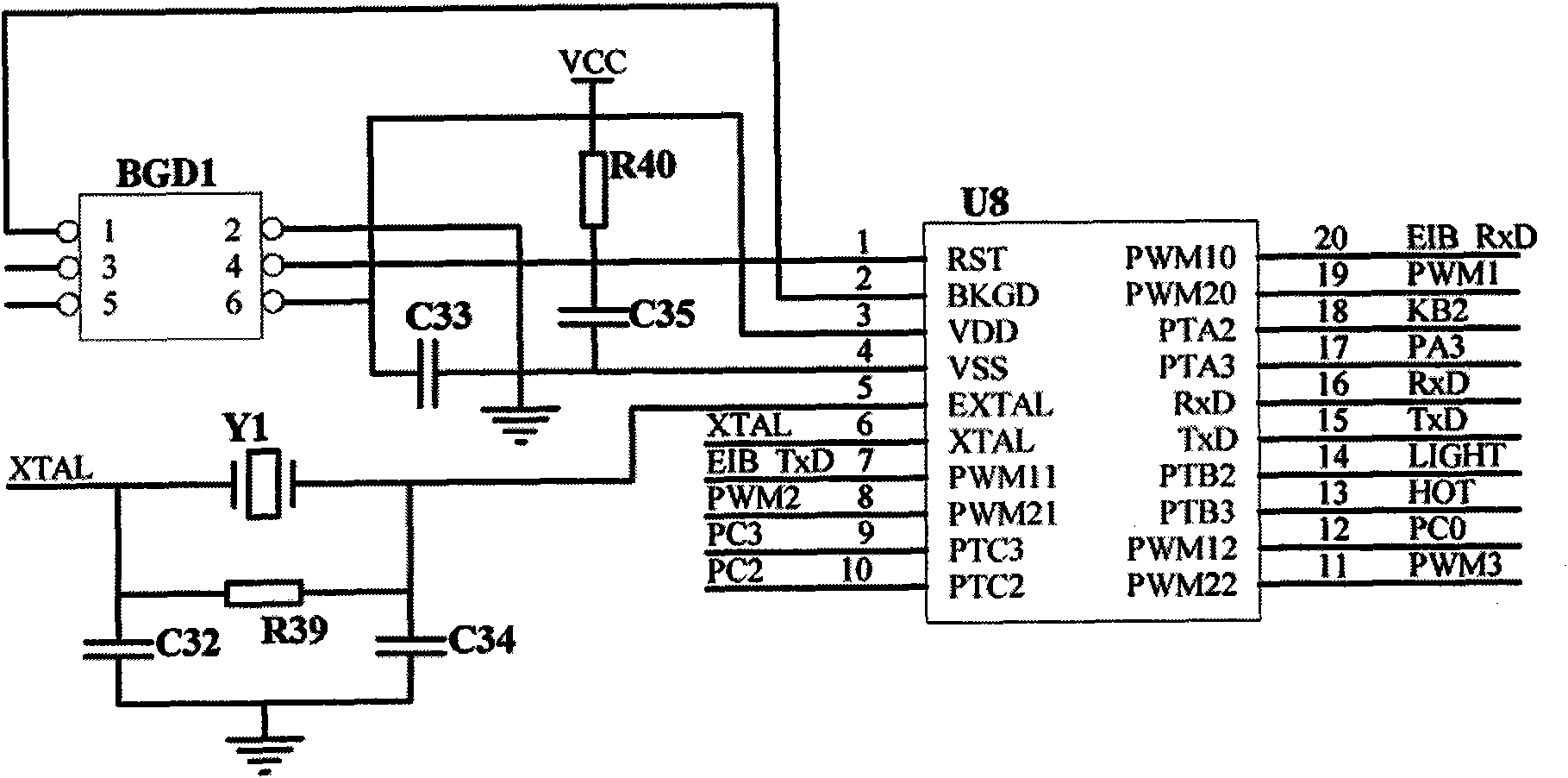

[0026] refer to figure 1 , figure 2 , a commercial LED lighting driver of the present invention, which includes

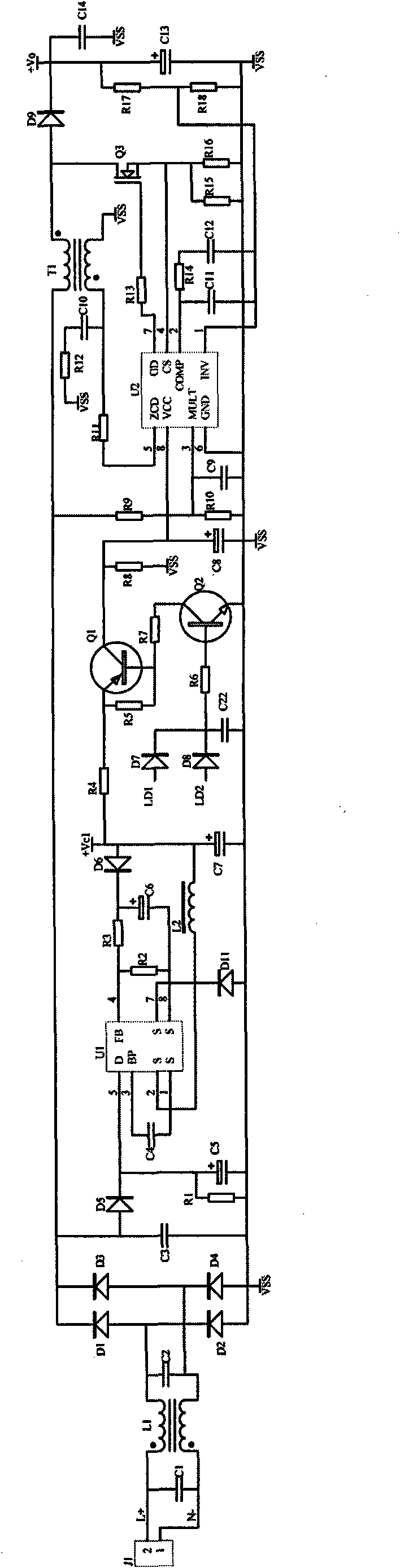

[0027] The electromagnetic filter module is EMC / EMI in the present invention, and its input end is connected to the power grid input, which can suppress and absorb the harmonics generated by the LED driver, so as not to affect the power grid quality; It is composed of filter capacitors C1 and C2 at both ends. Due to the quasi-resonant active power factor correction scheme, the harmonic influence of the drive on the grid is very small. Therefore, simple capacitor filtering and inductor harmonic suppression can achieve good EMC / EMI power grid quality control indicators.

[0028] The rectifier module, whose input end is connected to the output end of the electromagnetic filter module, rectifies and filters the input current, and is composed of rectifier diodes D1, D2, D3, D4 and filter capacitor C3 that form a bridge rectifier.

[0029] The active quasi-resonant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com