Diffraction optical element and optical pickup device

A technology of diffractive optical elements and optical pick-up devices, applied in the direction of optical elements, diffraction gratings, beam guiding devices, etc., can solve the problems of decreased precision, difficulty in focus control, difficulty in the linear range of focus error signals, etc., and achieve the goal of simplifying the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

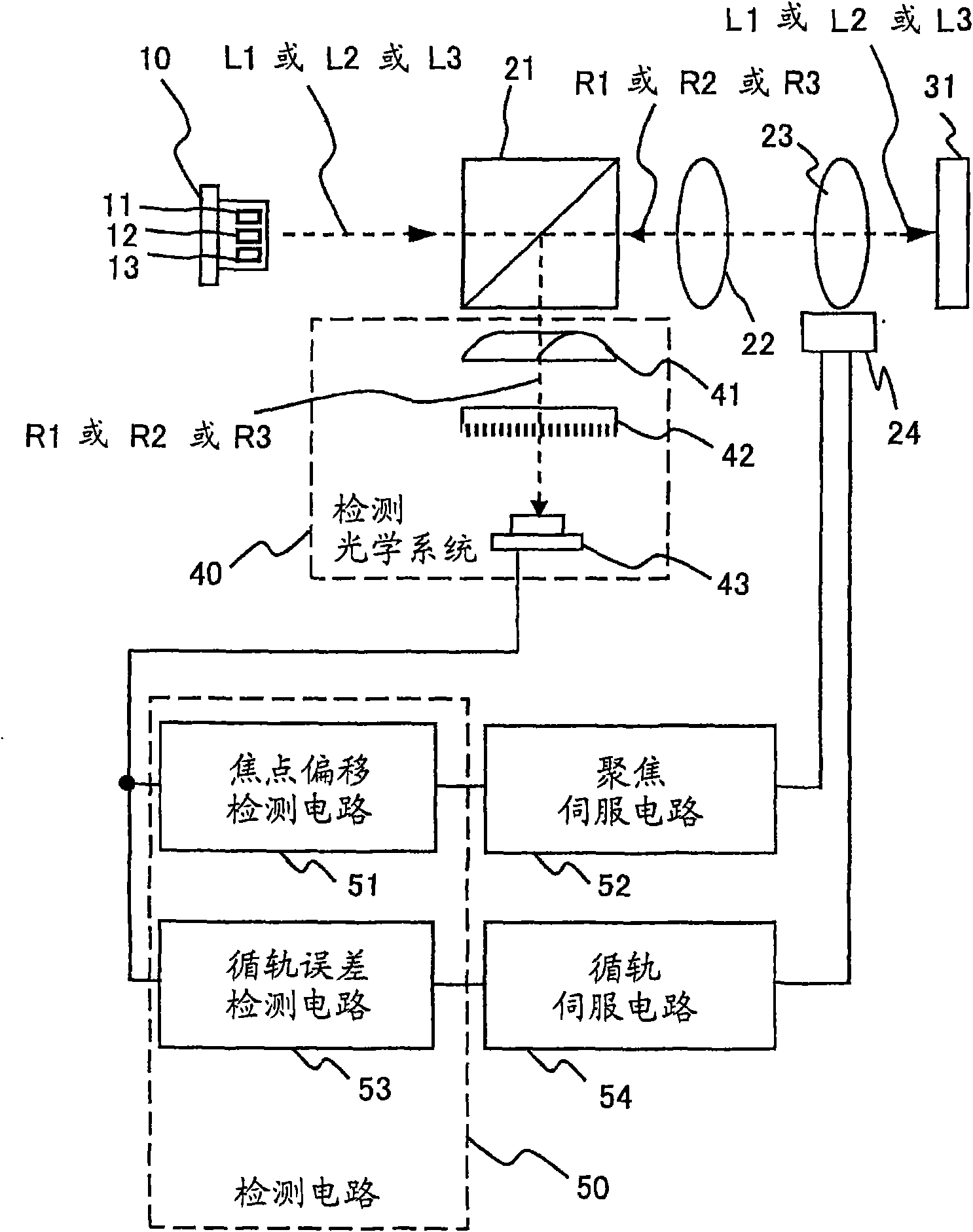

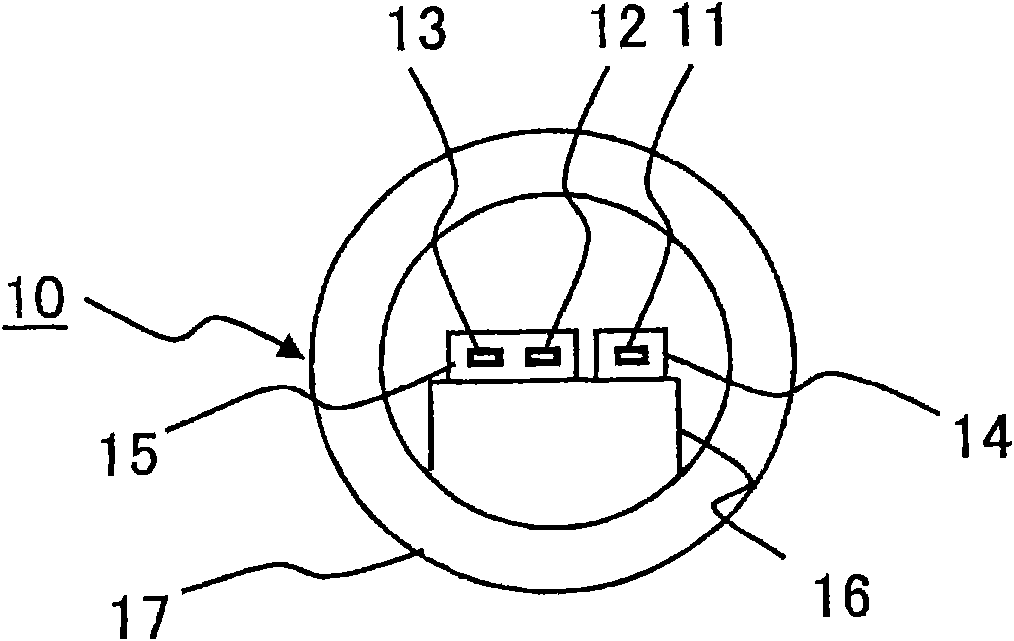

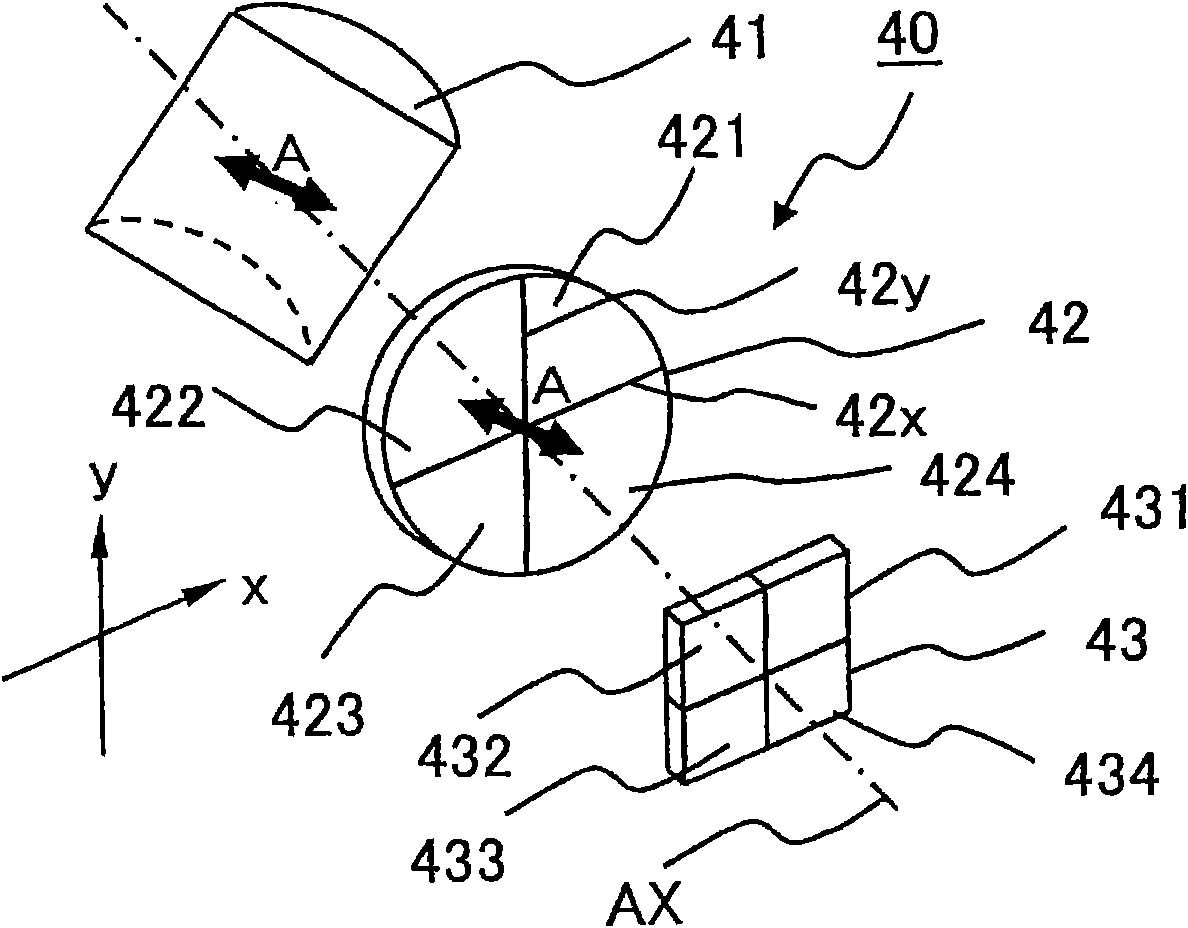

[0036] figure 1 It is a plan view schematically showing the configuration of the optical pickup device according to Embodiment 1 of the present invention. Such as figure 1 As shown, the optical pickup device of Embodiment 1 has: a semiconductor laser 10 as a laser light source, which excites a first laser light L1 having a first wavelength as a center wavelength, and a first laser light L1 having a second wavelength longer than the first wavelength as a center wavelength. 2 laser light L2, and a third laser light L3 having a third wavelength longer than the second wavelength as a center wavelength; a beam splitter 21; a laser beam (L1 or L2 or L3) emitted from the semiconductor laser 10 into parallel light Collimator lens (collimator lens) 22; Objective lens 23, it makes the laser light (L1 or L2 or L3) after emitting collimator lens 22 focus on the optical disk 31; And servo mechanism 24, it is used for carrying out the focus control of objective lens 23 and tracking cont...

Embodiment approach 2

[0071] Figure 15 It is a front view showing another semiconductor laser 10 a applicable to the optical pickup device according to Embodiment 2 of the present invention. exist figure 2 In the above, the semiconductor laser 10 in which three laser excitation regions 11, 12, and 13 are arranged in a row on the heat dissipation member 16 is exemplified, but it is also possible to use Figure 15 As shown, the first semiconductor laser element 14 a and the second semiconductor laser element 15 a are stacked on the heat dissipation member 16 . Here, the case where the second semiconductor laser element 15a has two laser excitation regions was exemplified, but the present invention is not limited to this aspect, and the number of semiconductor laser elements may be three. In addition, the optical pickup device of Embodiment 2 is the same as the optical pickup device of Embodiment 1 above except for the above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com