Y/silicate compound molecular sieve and method for preparing same

A technology of composite molecular sieve and pure silicon molecular sieve, applied in the field of new composite catalytic materials and their preparation, to achieve the effect of increasing straight chain alkanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] (1) Preparation of reaction mixture gel

[0022] Mix Y-type molecular sieve, sodium hydroxide, distilled water, templating agent and silicon source evenly under stirring to make a reaction mixture gel, and the molar ratio of each component is as follows:

[0023] (0~1.3)Na 2 O:(34.4~110)H 2 O:(0.75~11.3)SiO 2 : (0.046~0.7)R, SiO 2 / Y (mass ratio) = 0.1 ~ 7; the preferred ratio is: (0 ~ 1.2) Na 2 O:(42~97)H 2 O:(1~8)SiO 2 : (0.072~0.6)R, SiO 2 / Y (mass ratio) = 0.2 ~ 5; in the formula, R represents the template agent, and Y represents the Y-type molecular sieve;

[0024] (2) Crystallization

[0025] The reaction mixture gel prepared in (1) is crystallized at 80-180°C for 12-70h, the optimum temperature is 100-160°C, and the optimum crystallization time is 14-48h.

[0026] (3) After the crystallization is completed, a core-shell composite molecular sieve is obtained by suction filtration and washing.

[0027] The preparation method of the reaction mixture gel de...

Embodiment 1

[0038] Add 1.0g of sodium hydroxide, 45ml of distilled water, and 12g of NaY to the beaker successively, stir well, then add 15ml of tetrapropylammonium hydroxide aqueous solution (the content of tetrapropylammonium hydroxide is 25wt%), stir for 10min, and finally add 32ml of silicon Sol (SiO 2 content is 30wt%), stirred for 3 hours, loaded into synthetic bombs, and crystallized in an oven at 120°C for 32 hours. Then the obtained product is washed with distilled water until it becomes neutral to obtain a Y / Silicalite-I composite molecular sieve.

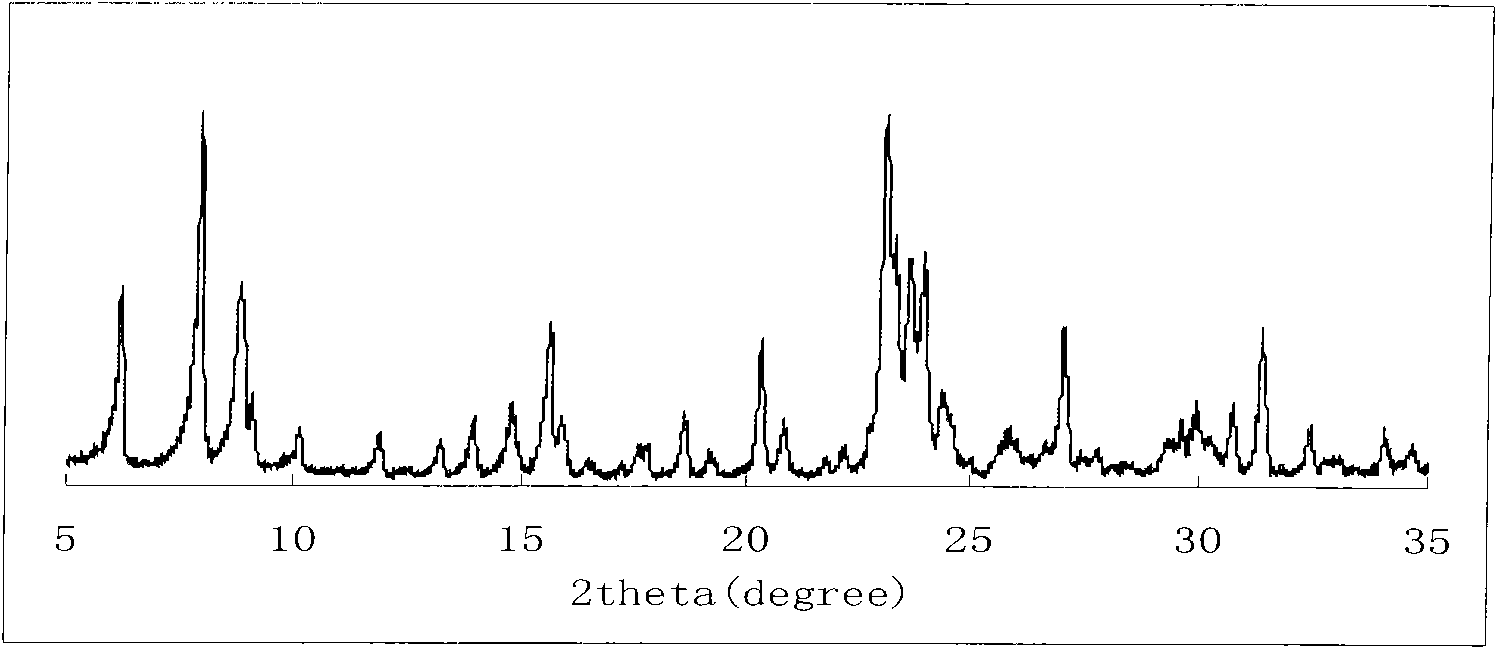

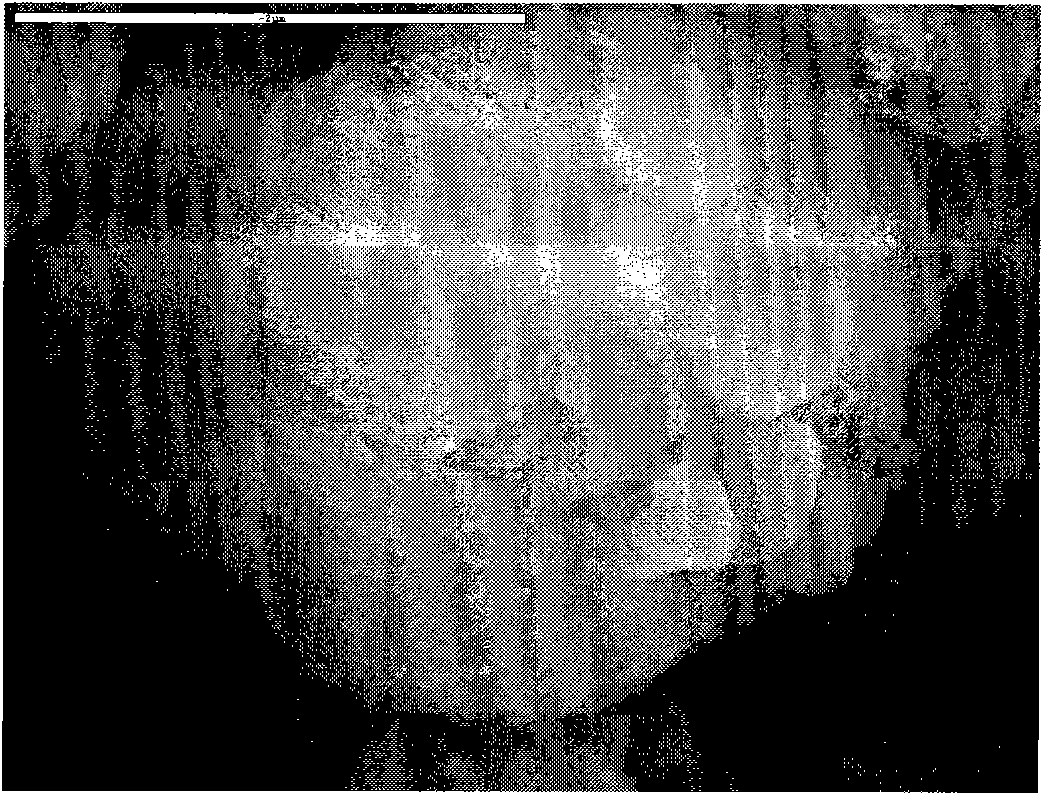

[0039] The XRD spectrum and scanning electron microscope photos of the composite molecular sieve are as follows: figure 1 , 2 shown. As can be seen from the XRD spectrum, in the spectrum, the diffraction peaks at 2θ=7.90°, 8.80°, (23.11±0.42)° are the main characteristic peaks of Silicalite-I, and 2θ=6.1°, 10.1°, 11.8°, The diffraction peaks at 15.6°, 18.6°, and 20.2° are characteristic peaks of Y-type molecular sieves. It shows...

Embodiment 2

[0041] Add 1.8g sodium hydroxide, 55ml distilled water, 9g USY molecular sieve to the beaker successively, stir evenly, then add 11ml tetrapropyl ammonium hydroxide, stir for 10min, finally add 32ml silica sol, stir for 3h, put into synthetic bomb, Crystallize in an oven at 160°C for 20h. Then the obtained product was washed with distilled water to neutrality to obtain USY / Silicalite-I composite molecular sieve.

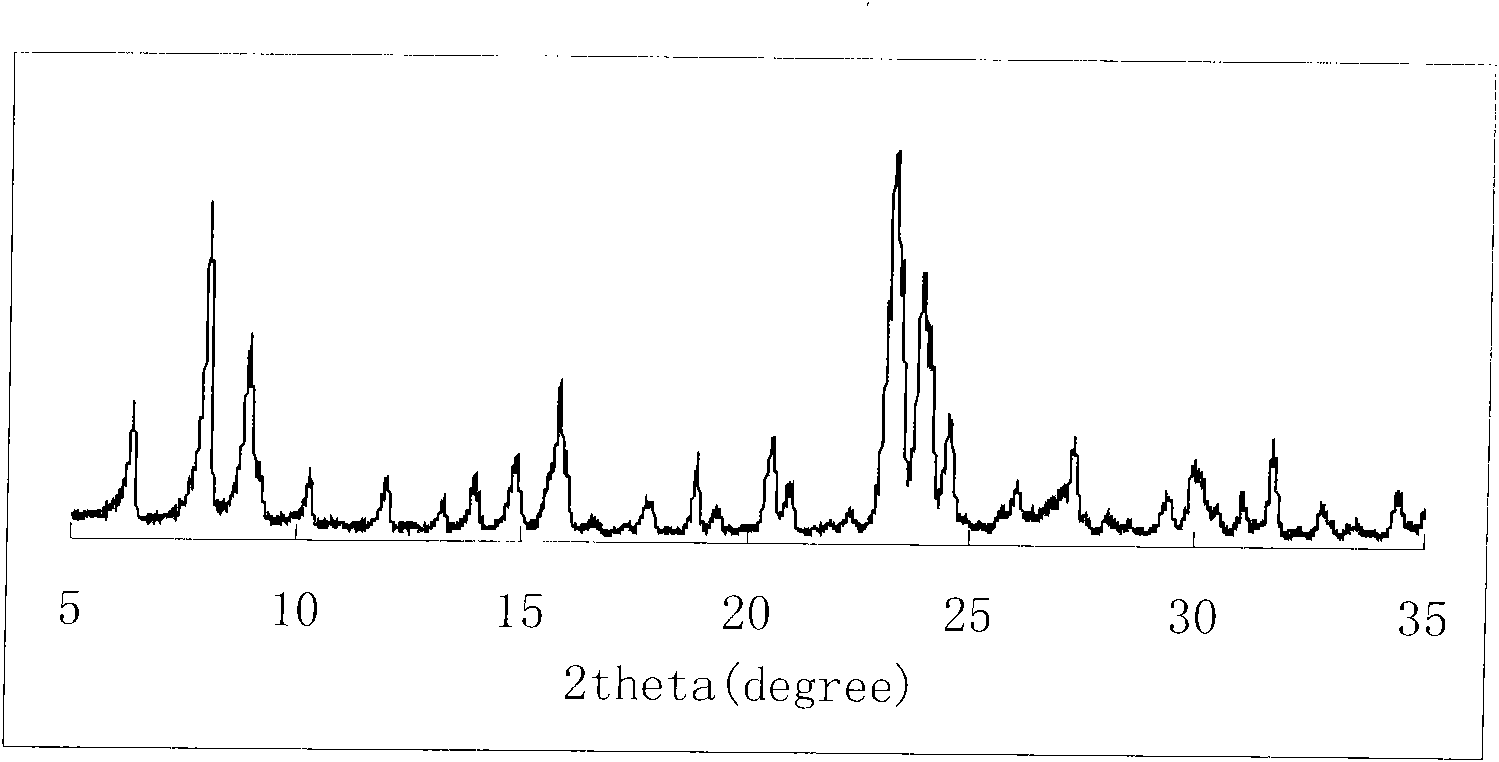

[0042] The XRD spectrum and scanning electron microscope photos of the composite molecular sieve are shown in image 3 , 4 . It can be seen from the XRD spectrum that there are main characteristic peaks of Silicalite-I and USY molecular sieves in the spectrum. It shows that the synthetic sample contains both Silicalite-I molecular sieve and Y-type molecular sieve. The content of Y molecular sieve in the compound molecular sieve is 33wt%. From the SEM photos, it can be clearly seen that the Y / Silicalite-I composite molecular sieve has a core-shell structure, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com