A kind of hydrorefining process

A technology for hydrotreating and hydrotreating reactions, which is applied in the petroleum industry, refining to remove heteroatoms, and treat hydrocarbon oil, etc., can solve the problems of easy coking at the top and frequent head skimming of the device, and prolong the life of the catalyst and the operation cycle of the device. , Improve the economic benefits of enterprises, and inhibit the effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

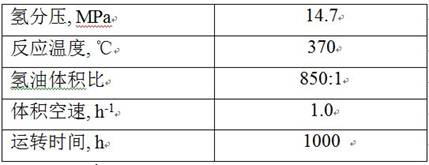

Embodiment 1

[0037] The reactor is filled with catalysts A1, B2, and C1 in equal proportions from the front to the rear, and the raw oil passes through the reactor bed after being contacted with hydrogen.

Embodiment 2

[0041] The reactor is loaded with A1, B1, and C1 catalysts in equal proportions from the front to the rear, and the raw oil passes through the reactor bed after being contacted with hydrogen.

Embodiment 3

[0045] The reactor is filled with catalysts A2, B2, and C1 in equal proportions from the front to the rear, and the raw oil passes through the reactor bed after being contacted with hydrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com