Manufacture method of environment-friendly wood substrate composite material

An environment-friendly and composite material technology, applied in the field of manufacturing environment-friendly wood-based composite materials, can solve the problems of waste accumulation, waste of resources, environment, pollution, etc., and achieve the effect of improving the performance of the board and increasing the added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

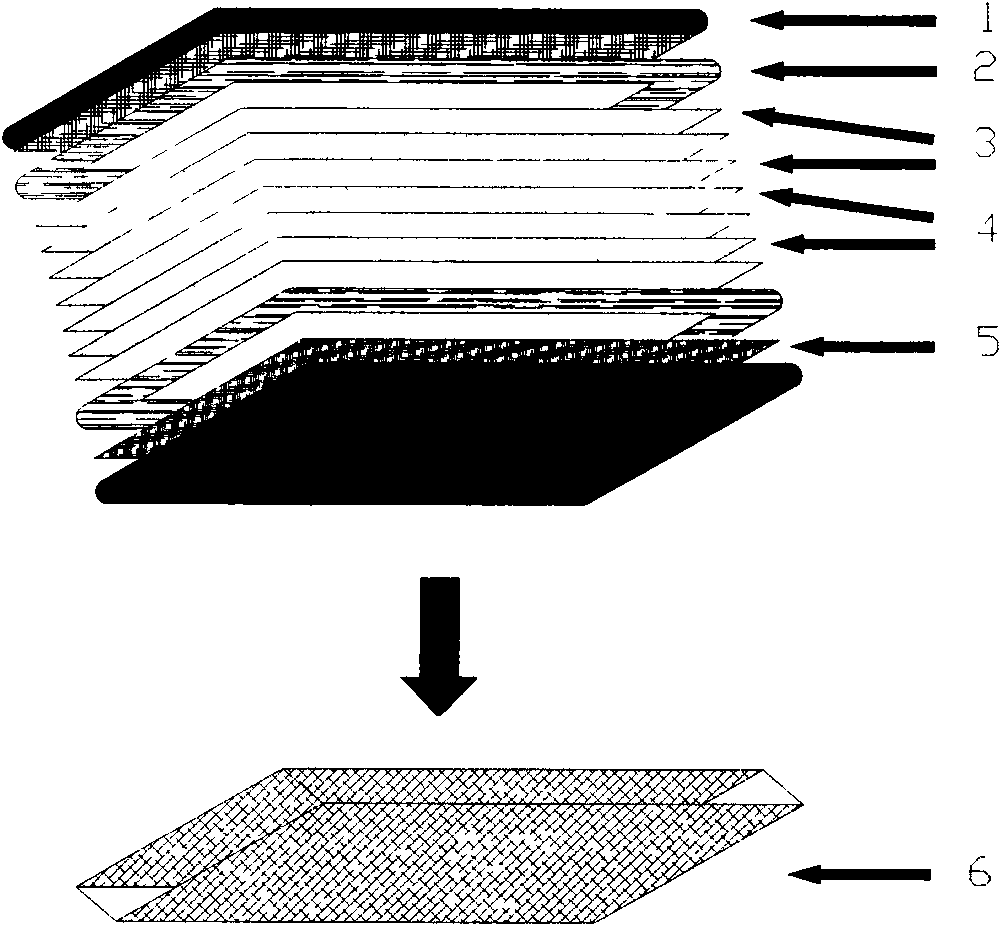

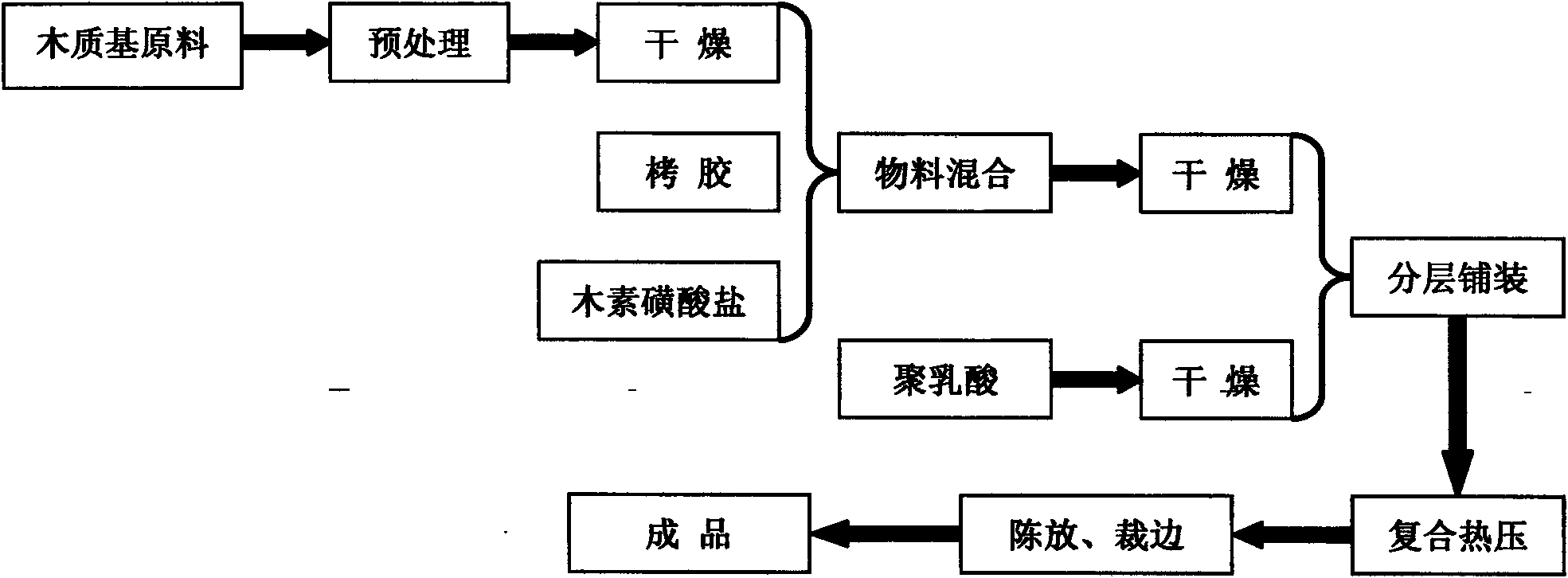

Embodiment 1

[0013] Wood fiber boards with a thickness of 3 mm are manufactured from wood fibers produced from forest residues and wood waste. Treat the wood fiber with 3% silane solution, then make the raw material treated at a drying temperature of 60°C for 1 hour, then add 5% larch extract and 5% lignosulfonate to the wood-based raw material for mixing, and The 5% degradable resin polylactic acid of the mixed material and the total material weight is paved in layers and pre-pressed into a slab, and then hot-pressed. The hot-pressing temperature is 160°C and the hot-pressing pressure is 3.5MPa. The time is 6 minutes, and finally the finished product will be put into storage after being aged and trimmed.

Embodiment 2

[0015] Wood fiber boards with a thickness of 6 mm are manufactured from wood fibers produced from forest residues and wood waste. Treat the wood fibers with 3% isocyanate solution, and then treat the raw materials at a drying temperature of 40°C for 20 minutes, then add 5% larch extract and 10% lignosulfonate to the wood-based raw materials for mixing. The 5% degradable resin polylactic acid of the mixed material and the total material weight is paved in layers and pre-pressed into a slab, and then hot-pressed. The hot-pressing temperature is 170°C, the hot-pressing pressure is 4MPa, and the hot-pressing time The time is 10 minutes, and finally the finished product is put into storage after being aged and trimmed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com