Method and device for laminating mainly plate-shaped workpieces with the use of pressure and heat

A technology of heat action and workpiece, applied in the direction of chemical instruments and methods, lamination, lamination system, etc., can solve the problems affecting the cost efficiency of module manufacturing, achieve the effects of manufacturing economy, improving operation reliability, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

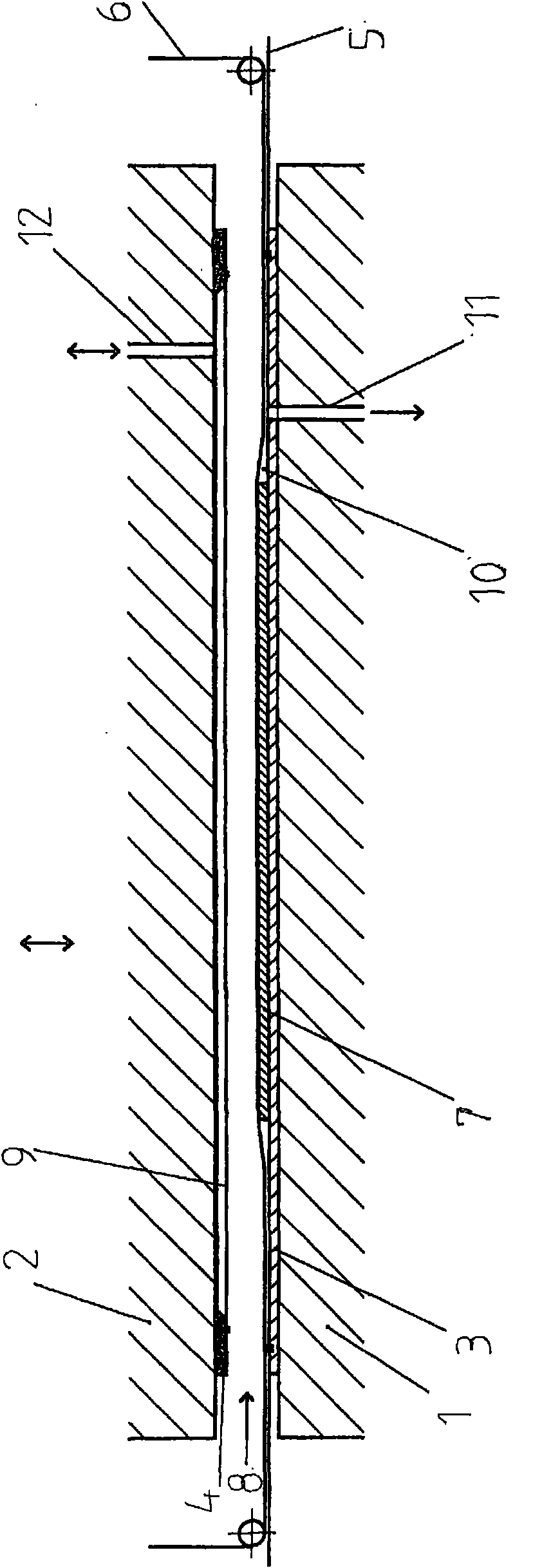

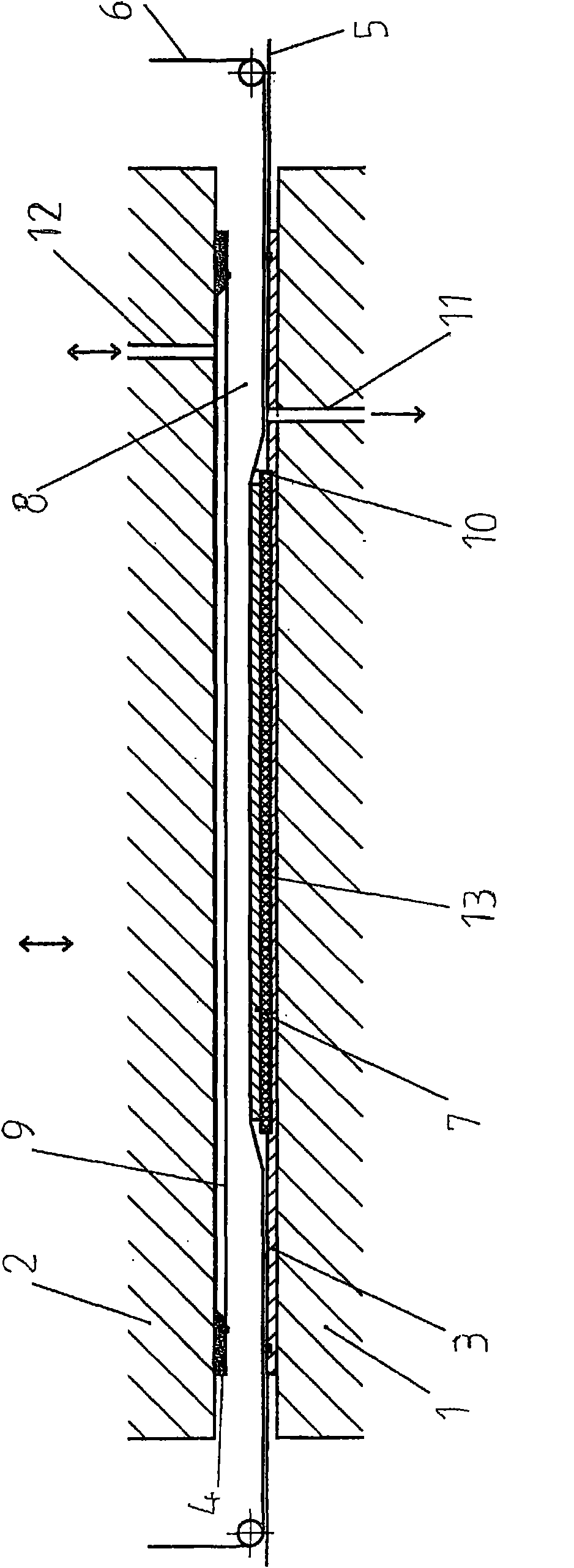

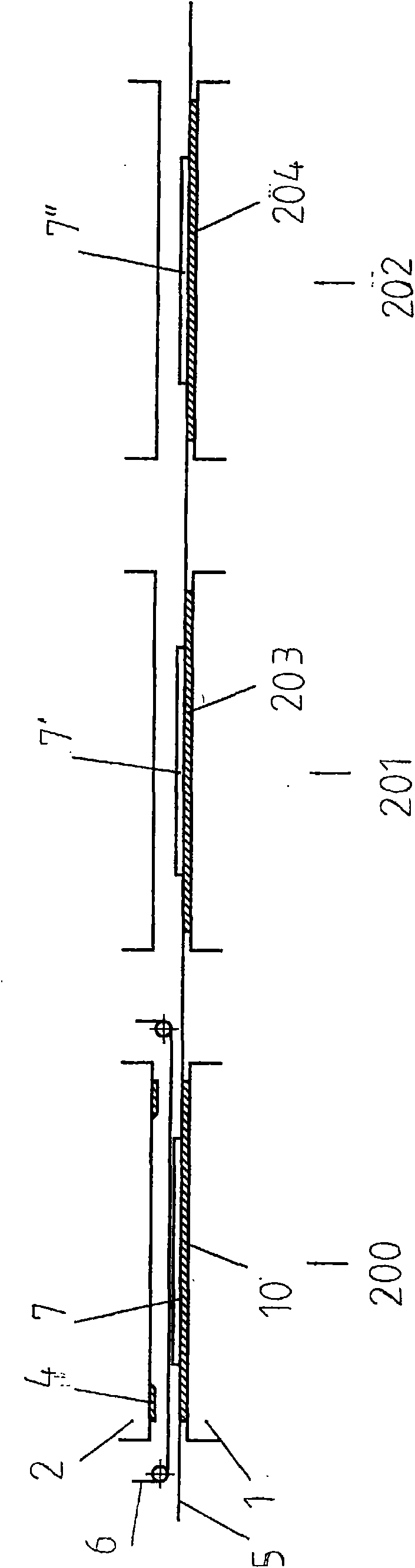

[0034] figure 1 A vacuum lamination press with a press lower part 1 , a press upper part 2 as well as a heating plate 3 and a sealing frame 4 is shown in a schematic partial side view. A conveyor belt 5 and a separating film 6 run between the heating plate 3 and the sealing frame 4 . On the heating plate 3, between the conveyor belt 5 and the release film 6, a workpiece 7 is arranged for pre-lamination after the press shown is closed. The heating plate 3, the press upper part 2 and the sealing frame 4 form the boundary of the vacuum chamber 8 when the press is closed, which is divided by the insulating membrane 6 into a space delimited by the press upper part 2, the sealing frame 4 and the insulating membrane 6. The pressure half 9 and a product half 10 delimited by the heating plate 3 and the insulating film 6 . The product half 10 can be evacuated via a channel 11 which is only schematically shown, while the pressure half 9 can likewise be evacuated or charged with compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com