Deslagging and dephosphorizing method of electric stove

An electric furnace and dephosphorization technology, which is applied in the field of steelmaking dephosphorization, can solve the problems of low steel cleanliness, market demand, and high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

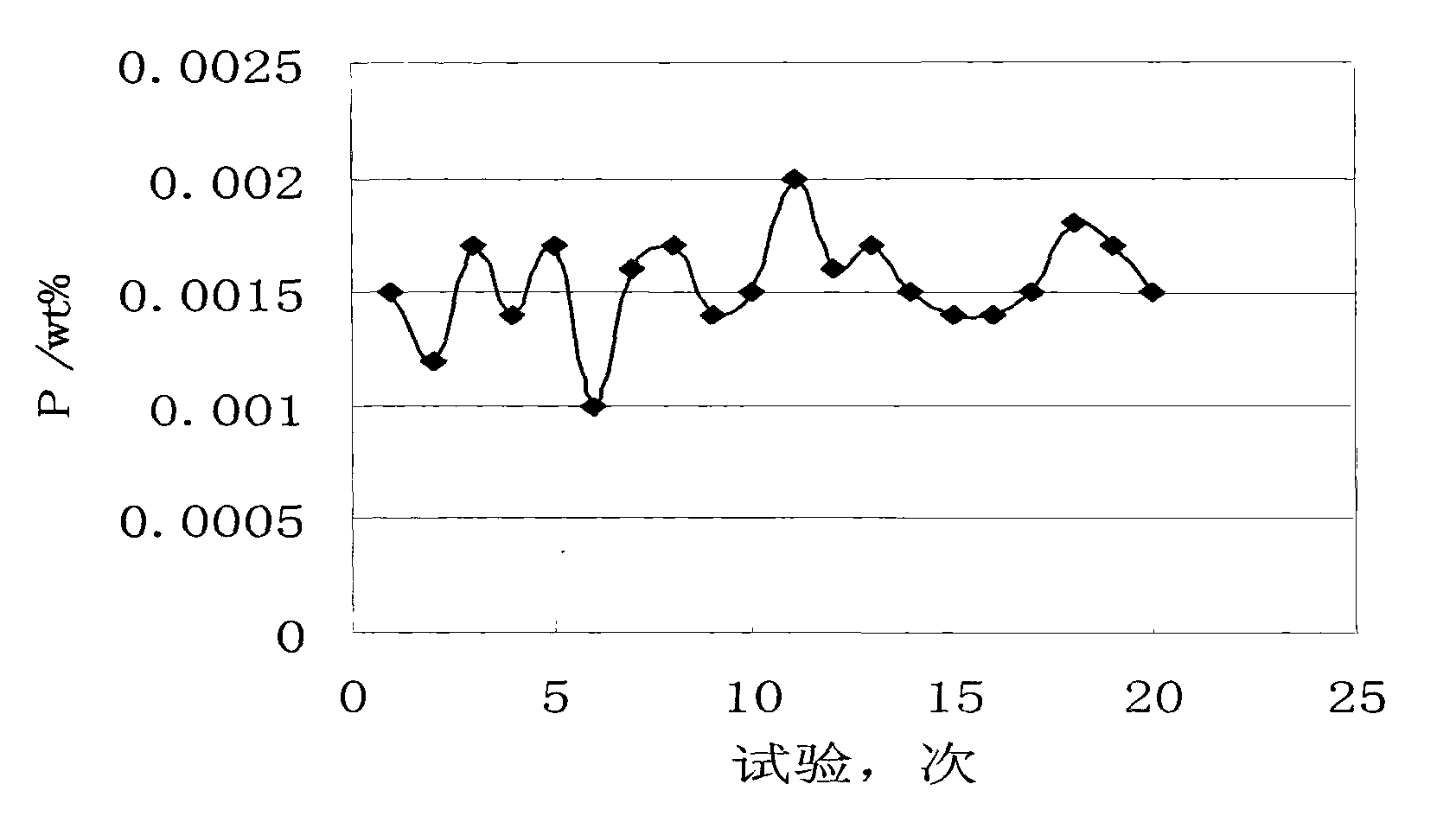

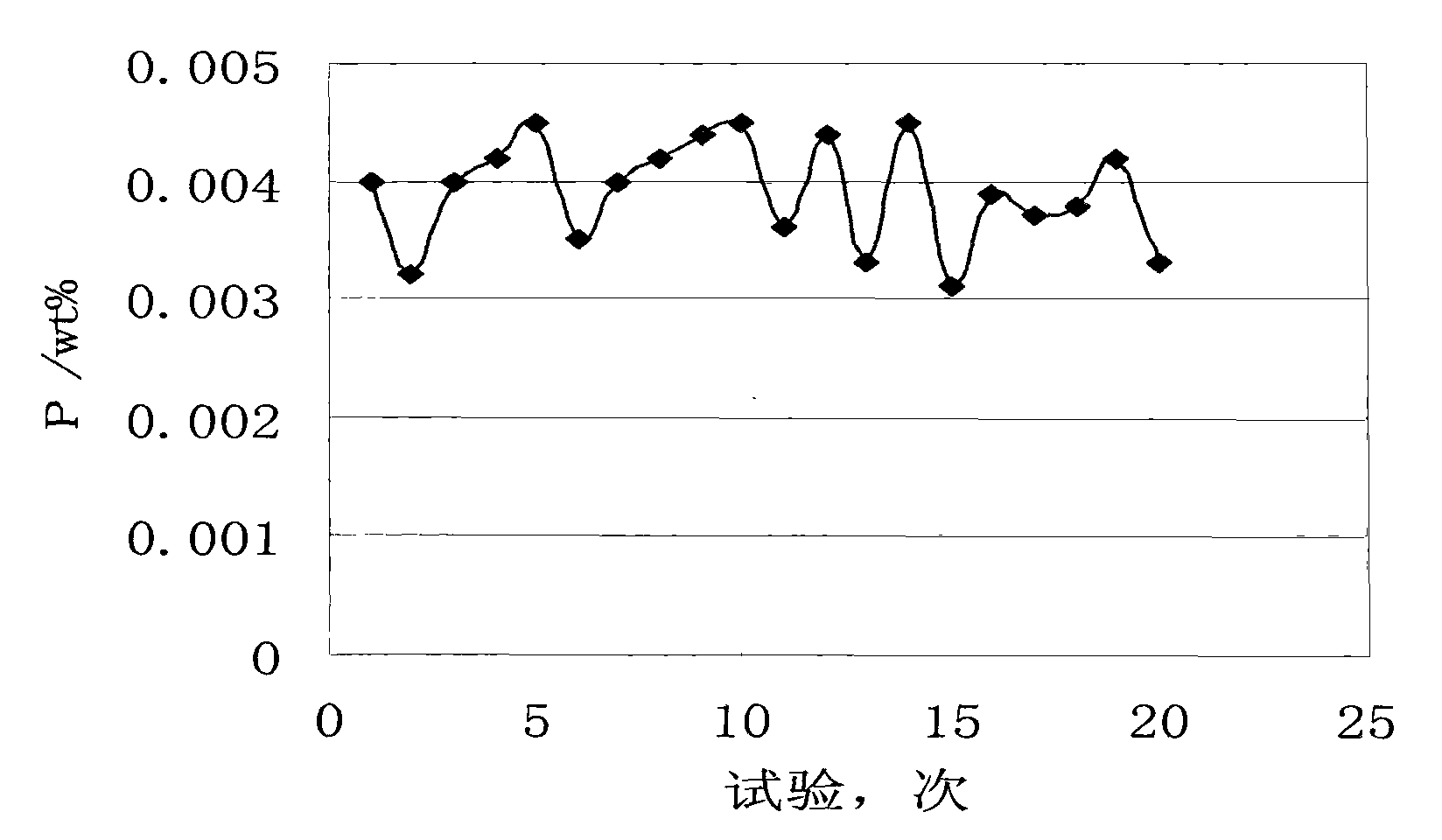

Examples

Embodiment 1

[0023] A method for slagging and dephosphorization of electric furnace, and its process steps:

[0024] 1) Slag making: add molten iron in the primary electric furnace, add scrap steel, blow oxygen to smelt, add active lime to 40kg / ton steel for slagging; add fluorite to 4kg / ton steel to adjust the properties of the slag to the requirements;

[0025] 2) Perform the first slag discharge: 20-22 minutes after oxygen blowing and smelting, and the temperature of molten steel rises to 1500~1505℃, the slag discharge starts, and the slag discharge accounts for 65% of the total slag volume, and phosphorus reduction is controlled. To a weight percentage of 0.014%;

[0026] 3) Carry out the second slagging: add active lime to 12kg / ton steel for slagging;

[0027] 4) Perform the second slag discharge: blow oxygen for 8-9 minutes, when the temperature of the molten steel rises to 1520-1530℃, start the second slag discharge, the slag discharge is 65% of the total slag volume, and the phosphorus red...

Embodiment 2

[0032] A method for slagging and dephosphorization of electric furnace, and its process steps:

[0033] 1) Slag making: add molten iron in the primary electric furnace, add scrap steel, and after oxygen blow smelting, add active lime to 42kg / ton steel for slagging; add fluorite to 4.2kg / ton steel to adjust the properties of the slag to the requirements ;

[0034] 2) Perform the first slag discharge: after 24 to 26 minutes of oxygen blowing and smelting, and the temperature of the molten steel rises to 1504~1507℃, the slag discharge starts, and the slag discharge accounts for 67% of the total slag volume, and the phosphorus reduction is controlled. To a weight percentage of 0.0125%;

[0035] 3) Carry out the second slagging: add active lime to 14kg / ton steel for slagging;

[0036] 4) Perform the second slag discharge: blow oxygen for 9 minutes, when the temperature of molten steel rises to 1535~1540℃, start the second slag discharge, the slag discharge is 68% of the total slag volume,...

Embodiment 3

[0041] A method for slagging and dephosphorization of electric furnace, and its process steps:

[0042] 1) Slag making: add molten iron in the primary electric furnace, add scrap steel, blow oxygen to smelt, add active lime to 45kg / ton steel for slagging; add fluorite to 4.5kg / ton steel to adjust the properties of the slag to the requirements ;

[0043] 2) Perform the first slag discharge: After 28-30 minutes of oxygen blowing and smelting, and the temperature of molten steel rises to 1506~1510℃, the slag discharge starts, and the slag discharge accounts for 70% of the total slag volume, and the phosphorus reduction is controlled. To a weight percentage of 0.0116%;

[0044] 3) Carry out the second slagging: add active lime to 16kg / ton steel for slagging;

[0045] 4) Perform the second slag discharge: oxygen blow for 10 minutes, when the temperature of the molten steel rises to 1545~1550℃, the second slag discharge starts, the slag discharge amount is 70% of the total slag amount, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com