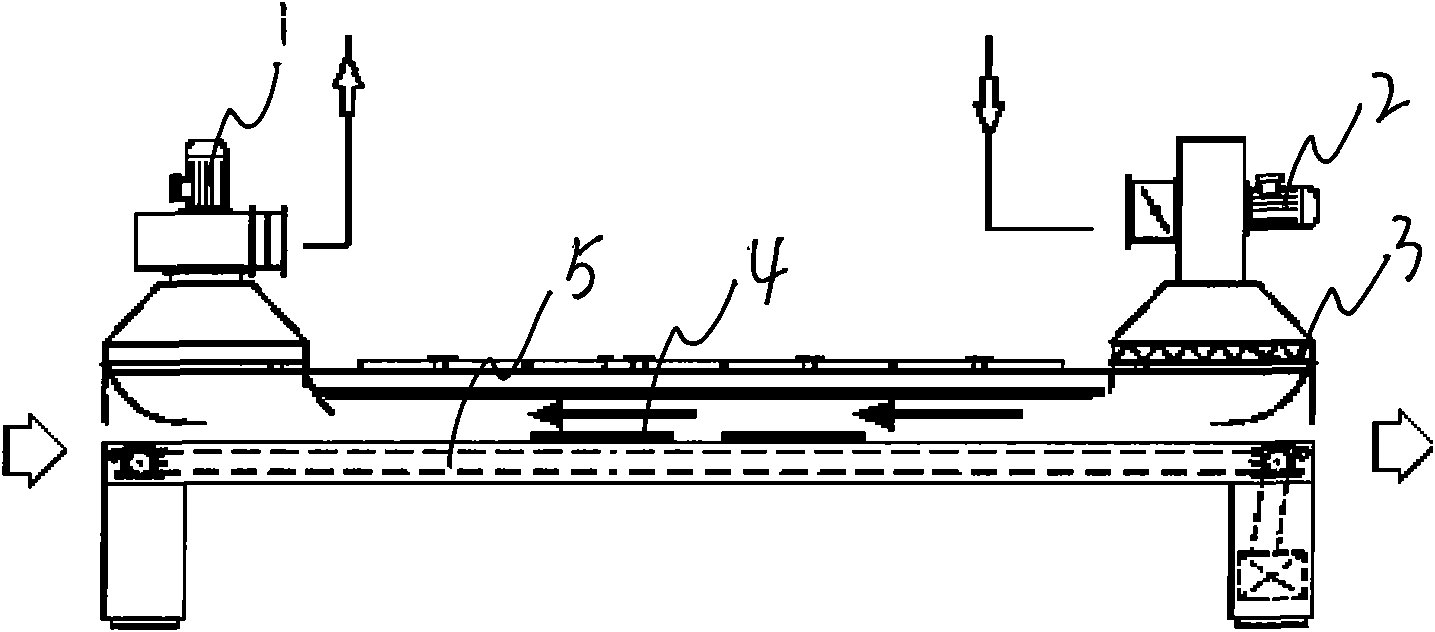

Headwind horizontal drier

A technology of drying machine and drying fan, which is applied in the direction of progressive drying machine, drying machine, drying solid materials, etc. It can solve the problems of slow drying speed, inability to achieve uniform drying, and small heating area of workpieces, so as to improve drying speed, The effect of increasing the heating area and increasing the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: with reference to attached figure 1 . Upwind horizontal dryer, which includes a dryer, one end of the dryer is provided with an inlet fan 2, and the other end is provided with an outlet fan 1, and the wind direction is opposite to the conveying direction of the workpiece 4, between the inlet fan 2 and the dryer There is heating and filter 3 between the air ducts, and heating and filter 3 are made of heater and filter, and filter is positioned at the rear portion of heater. The force generated by the wind speed in the wind direction is less than the adhesion force of the painted surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com