Process for reducing carbon dioxide emission in a power plant

A carbon dioxide and power generation device technology, applied in the direction of direct carbon dioxide emission reduction, carbon dioxide storage, chemical instruments and methods, etc., can solve the problems of increasing the total cost of the method and operational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

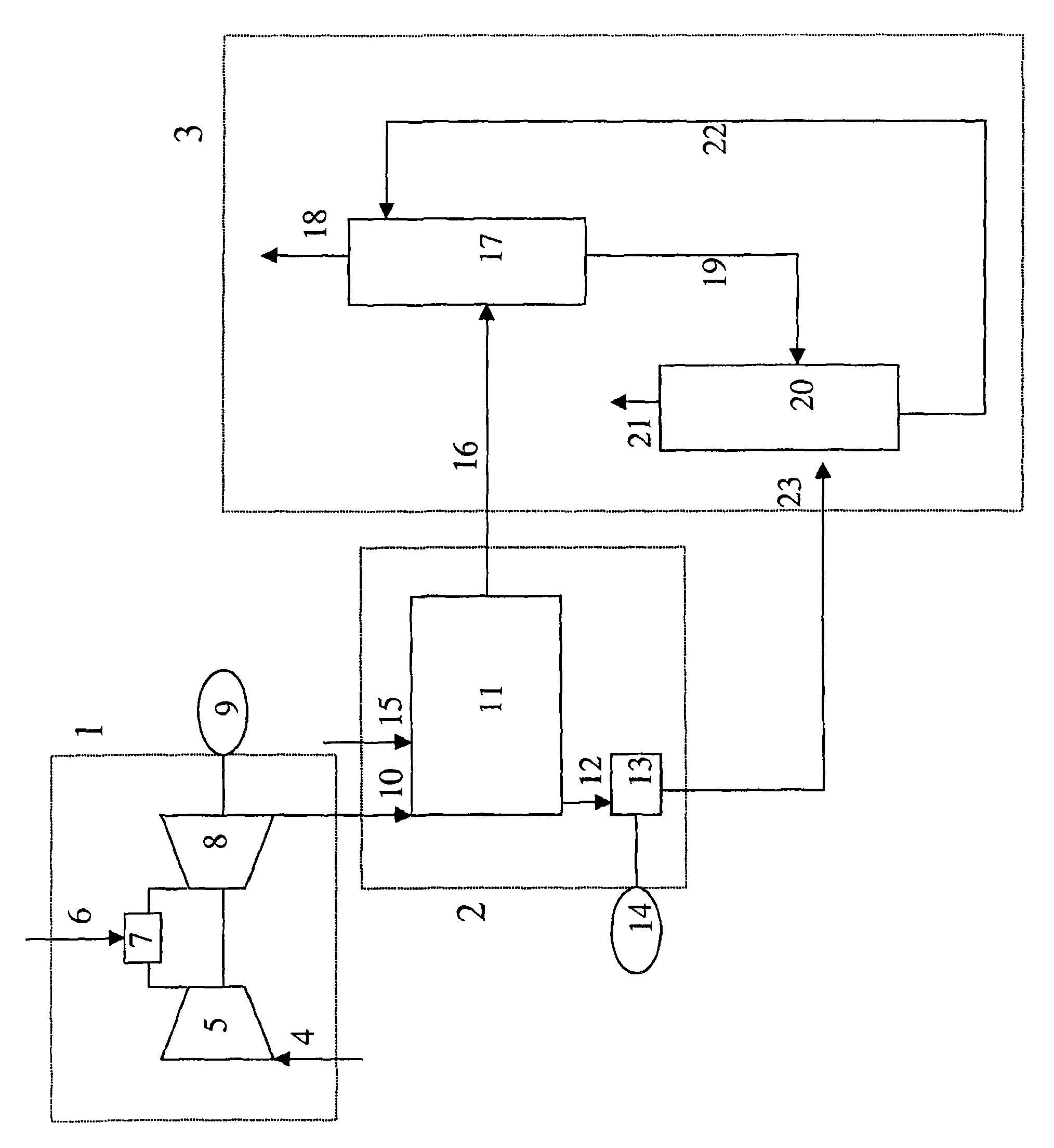

[0009] In the method, a power plant comprising at least one gas turbine is used. Typically, fuel and oxygen-containing gas are fed into the combustion zone of a gas turbine. In the combustion zone of a gas turbine, fuel is combusted to produce hot combustion gases. The hot combustion gases are expanded in a gas turbine (usually via an array of expander blades arranged in a row), and used to generate electricity by a generator. Suitable fuels for combustion in gas turbines include natural gas and syngas.

[0010] In step (a), the hot exhaust gas leaving the gas turbine is introduced into a heat recovery steam generator unit. The hot exhaust gas leaving the gas turbine has a certain high pressure. The pressure of the hot exhaust gas is determined by the setup and / or construction of the gas turbine. For example, a gas turbine typically includes a sequence of expander blades arranged in rows: by changing the number of expander blade rows, the back pressure of the gas turbine c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com