Device for de-sugaring and processing dairy product

A technology for processing equipment and dairy products, which is applied in the direction of dairy products, other dairy products, mixers, etc., can solve the problems of difficult to guarantee the quality of dairy products, low production efficiency, and failure to achieve, so as to achieve easy observation and control, quality assurance , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

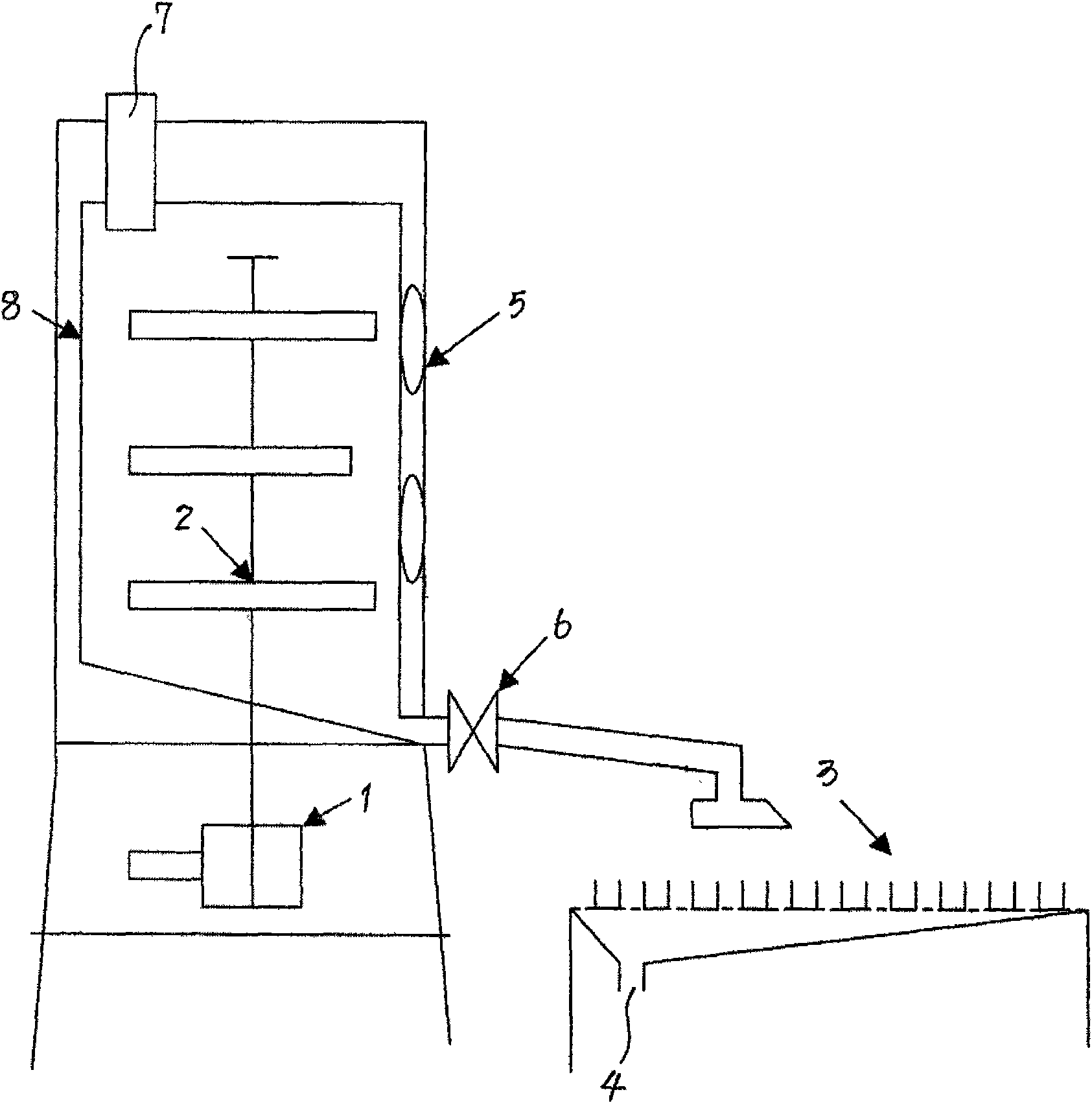

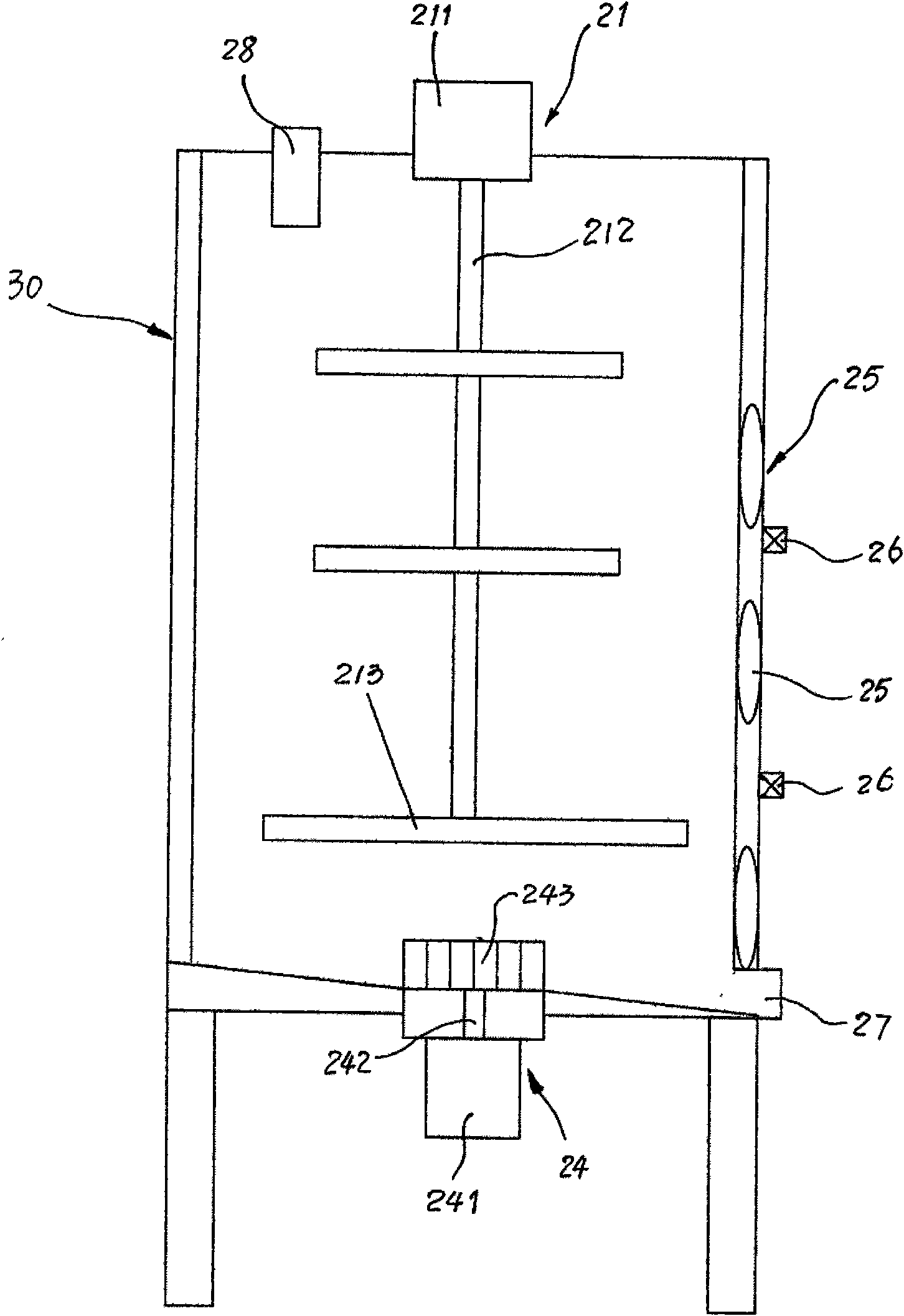

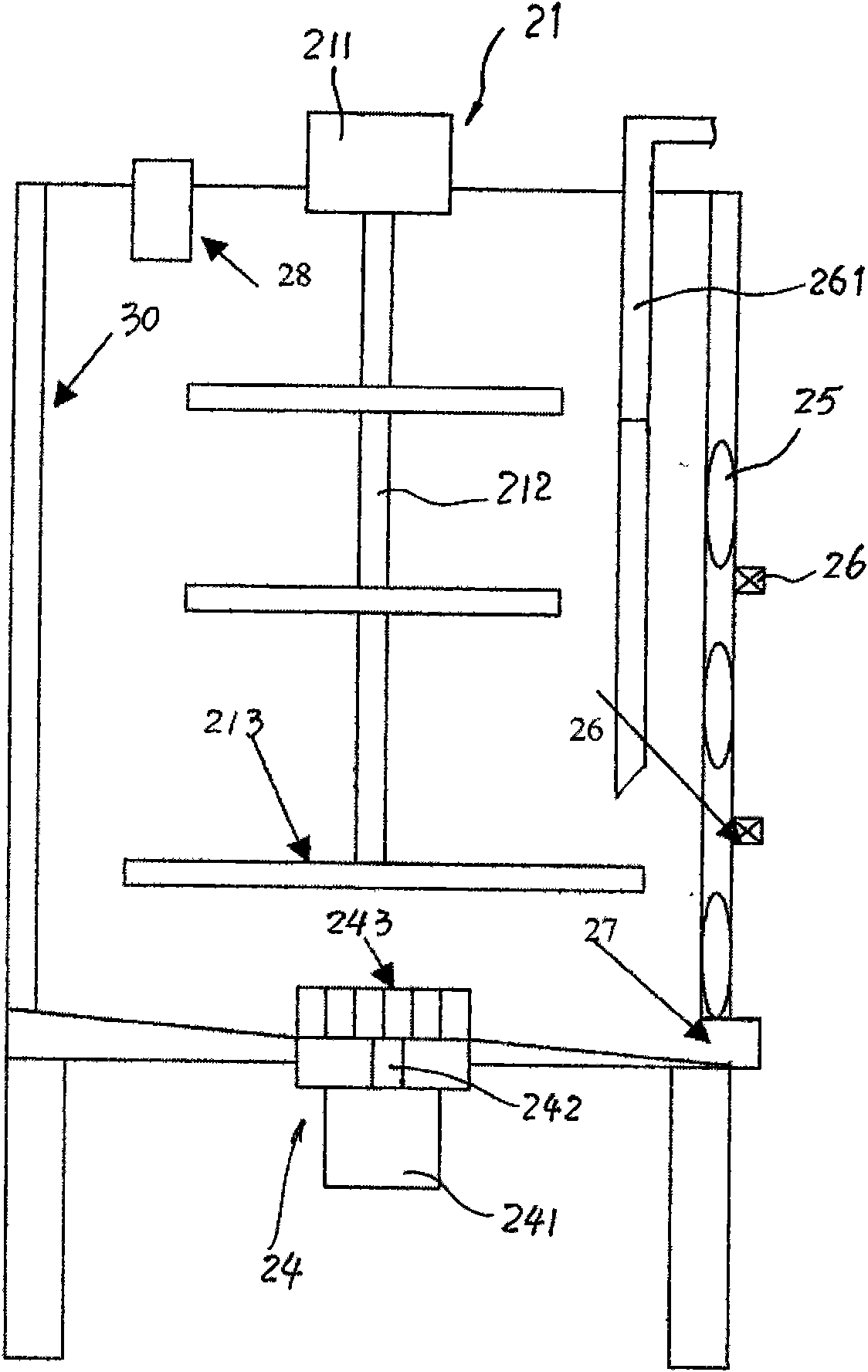

[0035] refer to figure 2 The tank body 30 described in Embodiment 1 of the present invention is an upright cylindrical shape with a volume of 2 cubic meters, a tank height of 3 meters, and a barrel inner wall diameter of 1.0 meters. The wall of the tank body 30 includes a temperature-regulating layer and an insulating layer. The temperature layer can be composed of cold and hot water circulation device, or it can be composed of electronic cooling and heating temperature adjustment device to ensure the processing temperature of the material liquid in the tank at each working stage. The top of the tank body 30 is provided with a feed opening 28, and the inner bottom of the tank body 30 is inclined, or flat, U-shaped, and a discharge opening 27 for shearing emulsified milk (reconstituted milk) is provided at the lowest point. The middle and lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com