Hybrid autothermal catalytic process for converting alkanes to alkenes and catalysts useful for same

A catalyst, alkane technology, applied in the direction of carbon compound catalyst, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as deactivation of chromium-based catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

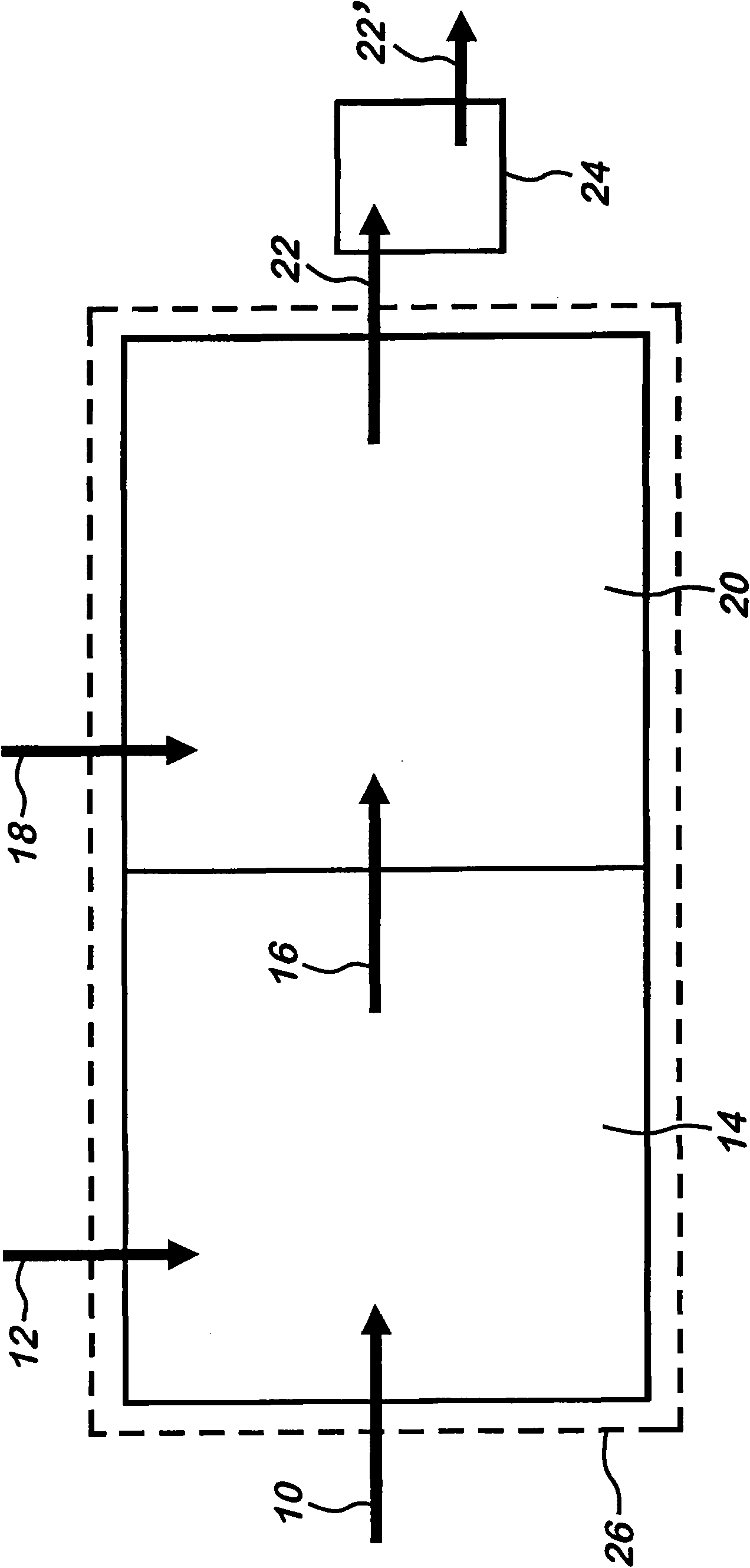

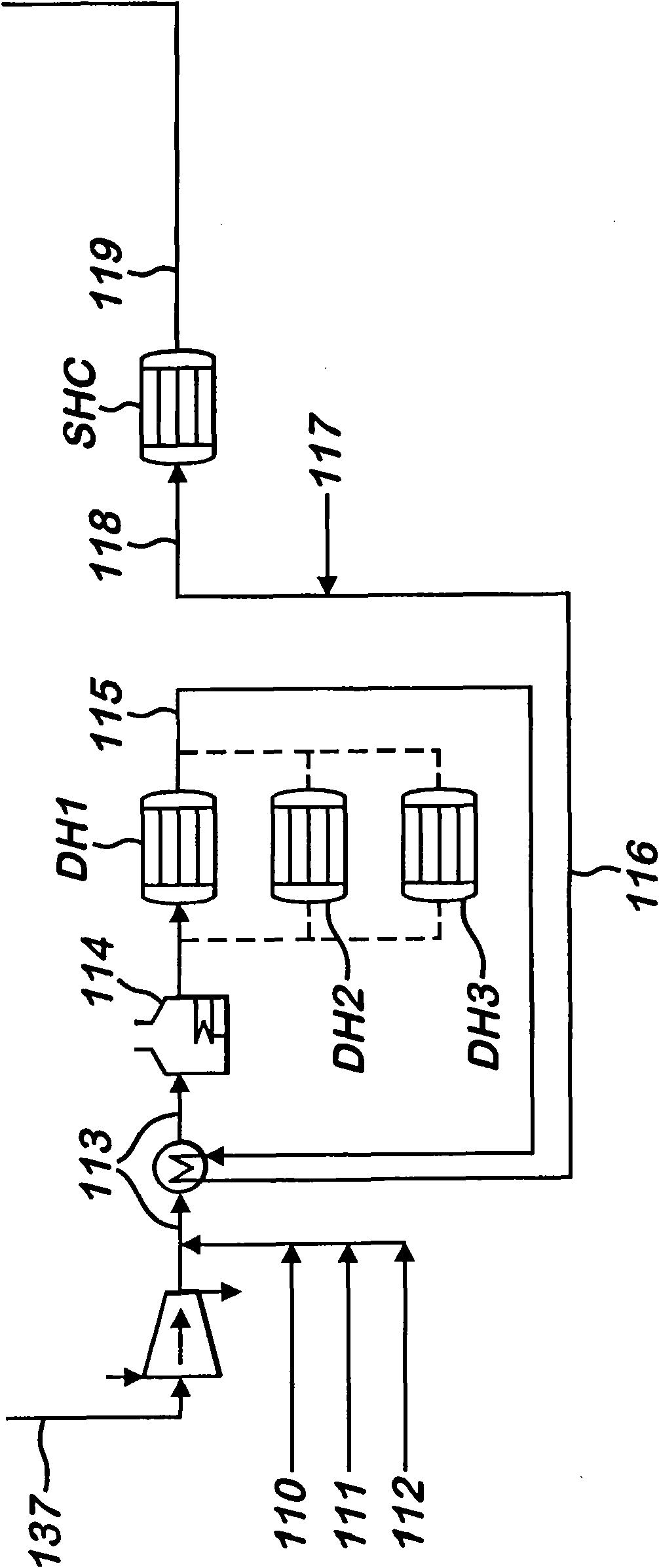

[0075] The following description is about figure 2 Schematic representation of the process equipment shown. Three mild oxidant shift reactors (SOC1, SOC2, SOC3), each comprising an oxidation reaction zone (not shown per se, but see figure 1 and related description above), wherein a suitable catalyst (also not shown per se, but can be found in figure 1 and related description above). One reactor at a time is operated for the conversion of propane to propylene in a heat-integrated mild oxidant conversion process. Catalyst regeneration is performed on a reactor when it is not in use, ie "offline". The mild oxidant shift reactors (SOC1, SOC2, SOC3) are automatically cycled on-line and off-line by a process control system (not shown).

[0076] The fresh (i.e. not containing any recycled material) feedstocks to the mild oxidant conversion reaction zone were: propane (110), 13140 kg / hr; carbon dioxide (111), 8573 kg / hr; nitrogen (112), 5287 kg / hr Hour. In addition to fresh f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com