Industrialized preparation method of WC-Co hard alloy with low cost and high performance

A cemented carbide, high-performance technology, applied in the field of industrialized preparation of WC-Co cemented carbide, can solve the problems of limited material quantity, high price, and inability to popularize, and achieve accurate control of phase purity, low price, and simplified production. The effect of the device

Active Publication Date: 2011-01-05

北硬科技香河有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with the current production equipment, these new sintering equipment are quite expensive, and the amount of materials prepared at one time is very limited, so the sintering process developed for this type of equipment can only be applied in the laboratory, but cannot be extended to practice. In industrial production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

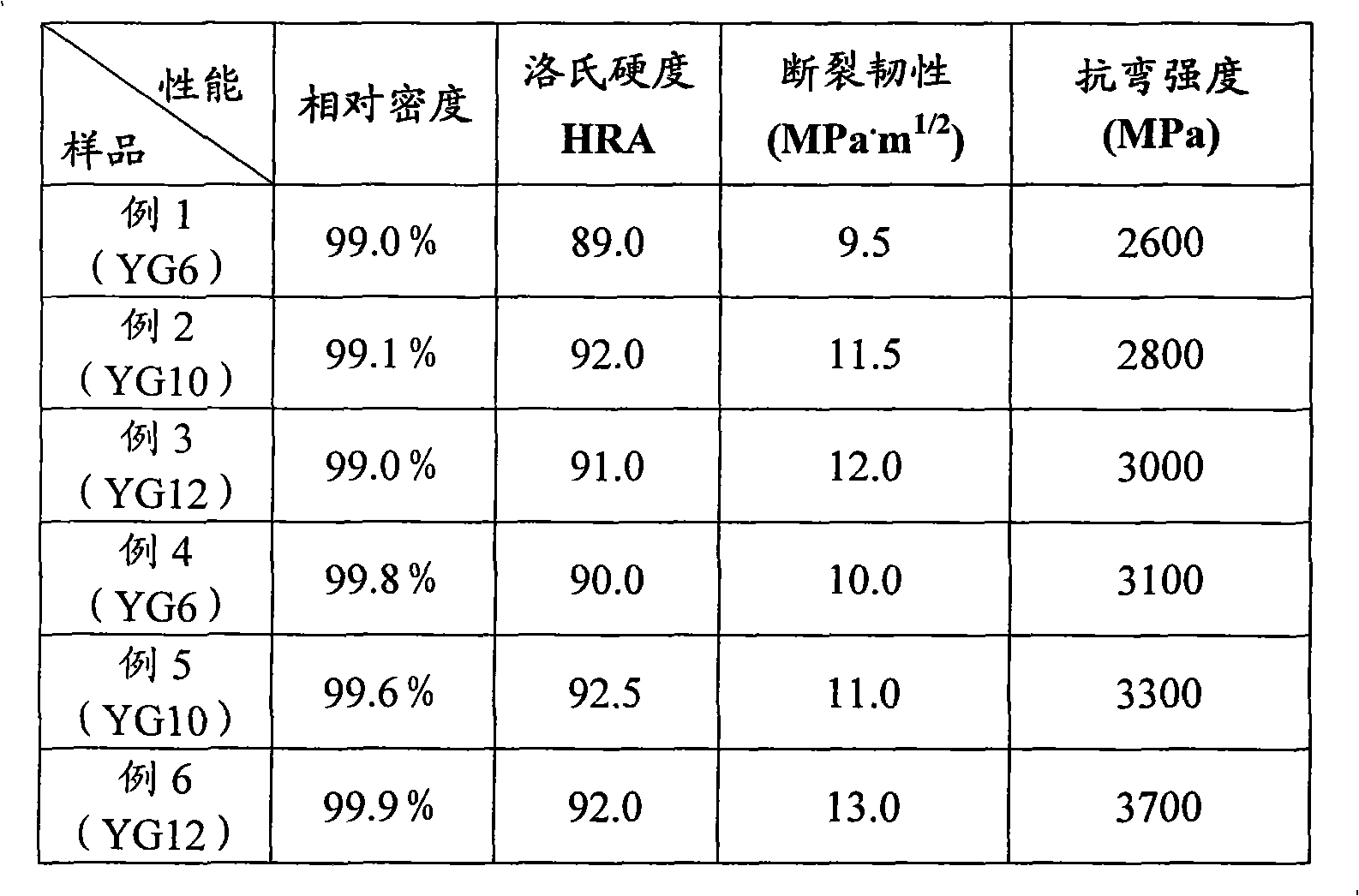

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

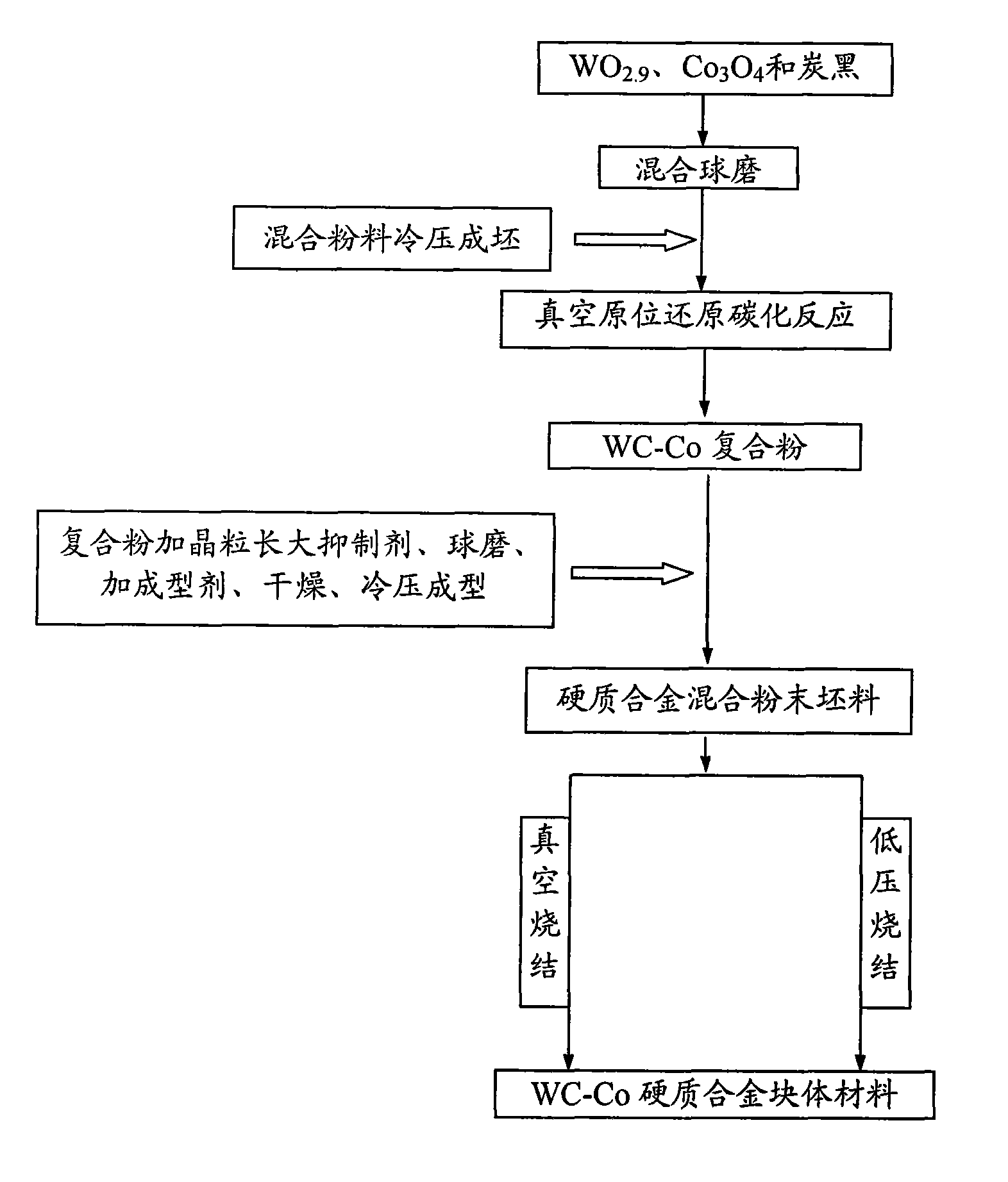

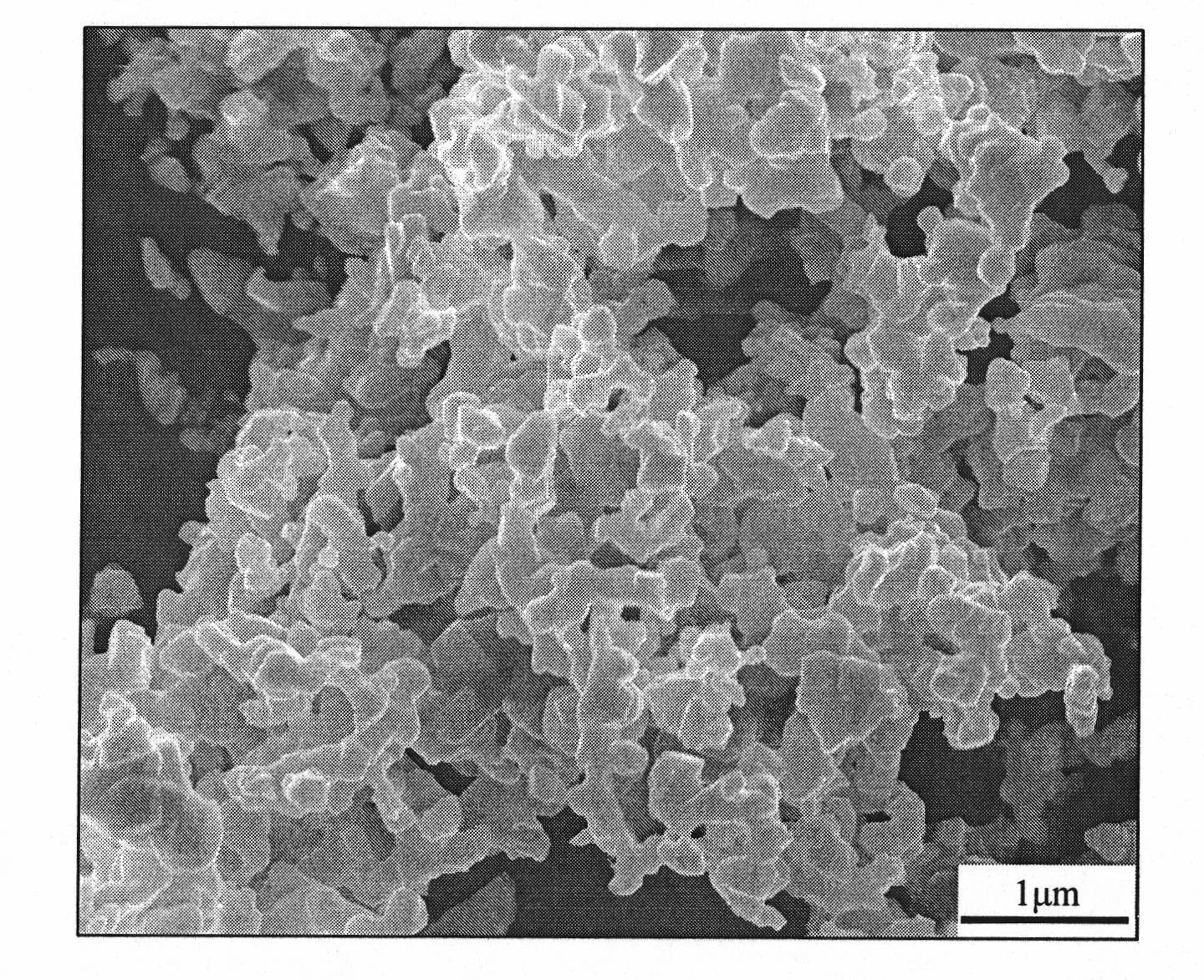

The invention relates to an industrialized preparation method of a WC-Co hard alloy with low cost and high performance, which belongs to the technical field of hard alloys and powder metallurgy. The method comprises the following steps: taking WO2.9, Co3O4 and carbon soot as raw materials, and computing the usage ratio of the three materials according to the requirement of the Co content in a final hard alloy block material; adding 0-1.0 percent by weight of grain growth inhibitor into the prepared WC-Co composite powder, and adding polyethylene glycol as a forming agent into a ball milling tank 4-8 hours before ball milling is finished, wherein 30-80ml of polyethylene glycol is added into the powder material per kilogram; acquiring WC-Co mixed powder with a nanocrystal structure after ball milling, and putting the mixed powder into a mould for press forming after vacuum drying; and sintering the mixed powder stock after press forming in a mode of vacuum sintering or low-pressure sintering. The industrialized preparation method markedly shortens a production period, the provided integrated preparation course markedly reduces the production cost while ensuring the high performance of the hard alloy and has a high performance-price ratio, and the preparation method is suitable for industrialized scale production.

Description

A low-cost and high-performance industrial preparation method of WC-Co cemented carbide technical field The invention relates to an industrialized preparation method of low-cost and high-performance WC-Co cemented carbide, which belongs to the technical field of cemented carbide and powder metallurgy. Background technique Due to its unique properties such as high hardness, wear resistance, flexural strength and good fracture toughness, WC-Co cemented carbide is widely used in the fields of cutting tools, molds, mining tools and wear-resistant parts. It is generally believed that the key technology for preparing high-performance cemented carbide lies in the preparation of WC and Co mixed powder and its sintering densification. The current basic route for preparing cemented carbide materials is to prepare WC powder and Co powder separately, then mix them uniformly by ball milling, and finally sinter and densify to obtain cemented carbide bulk materials. The primary link in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C29/08C22C1/05

Inventor 宋晓艳魏崇斌赵世贤

Owner 北硬科技香河有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com